New method for comprehensively treating benzyl alcohol production waste water and device of new method

A technology for the production of waste water and comprehensive treatment, which is applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems that benzyl alcohol cannot be realized and the investment is large, and achieve small investment, high recovery rate, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

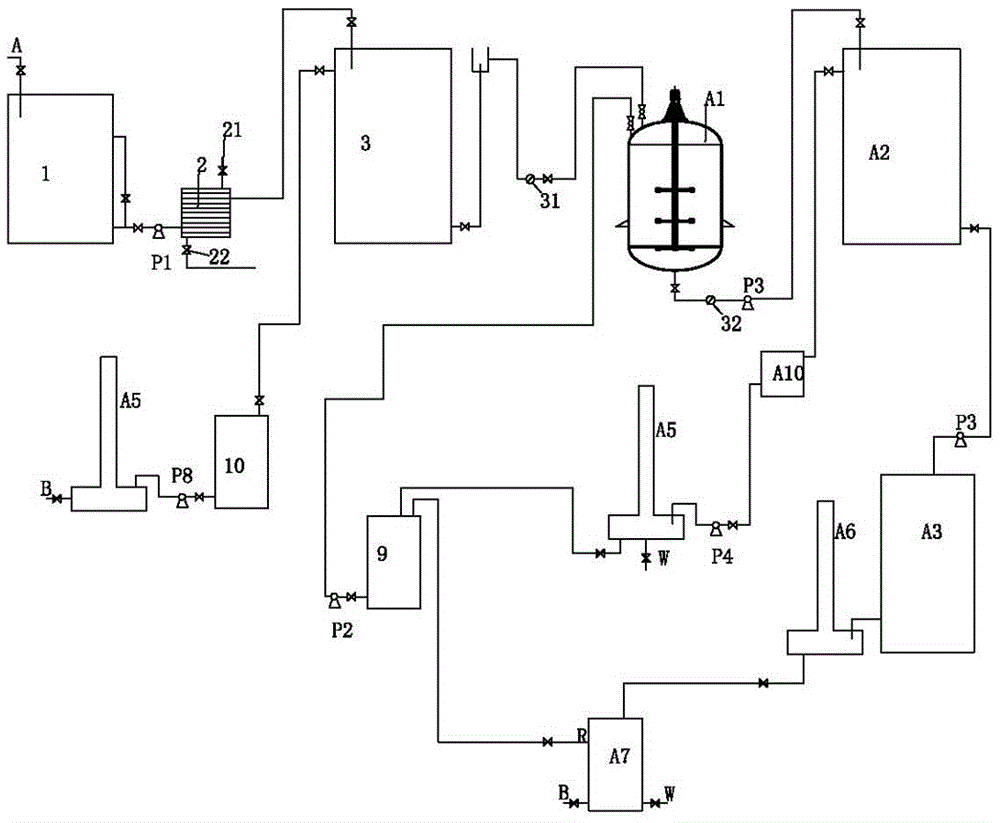

[0022] A recycling production device for comprehensive utilization of benzyl alcohol production wastewater, including a transfer tank 1, a crude product settling tank 3, and an extraction mixing tank A1, the bottom and middle of the transfer tank 1 are connected to the inlet of the condenser 2, and the outlet of the condenser 2 is connected to the crude product settling tank The top of 3 is connected, the lower water phase outlet of the crude product settling tank 3 is connected to the top wastewater inlet of the extraction mixing kettle A1 through the high overflow port on its right, the upper outlet of the crude product settling tank 3 is connected to the crude product oil tank 10, and the crude product oil tank 10 The transfer pump P8 is connected with the rectification tower A5, and the crude product oil phase is rectified to obtain benzyl alcohol with a purity >99%, which is discharged from outlet B and returned to production for use.

[0023] The dibenzyl ether inlet at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com