Antibacterial acrylic plate

An acrylic sheet and inorganic antibacterial agent technology, applied in the field of plastics, can solve the problems of restricting the widespread use of PMMA plastics, poor molding flow performance, low impact resistance, etc., and achieve the effects of high construction efficiency, long-term weather resistance, and good antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

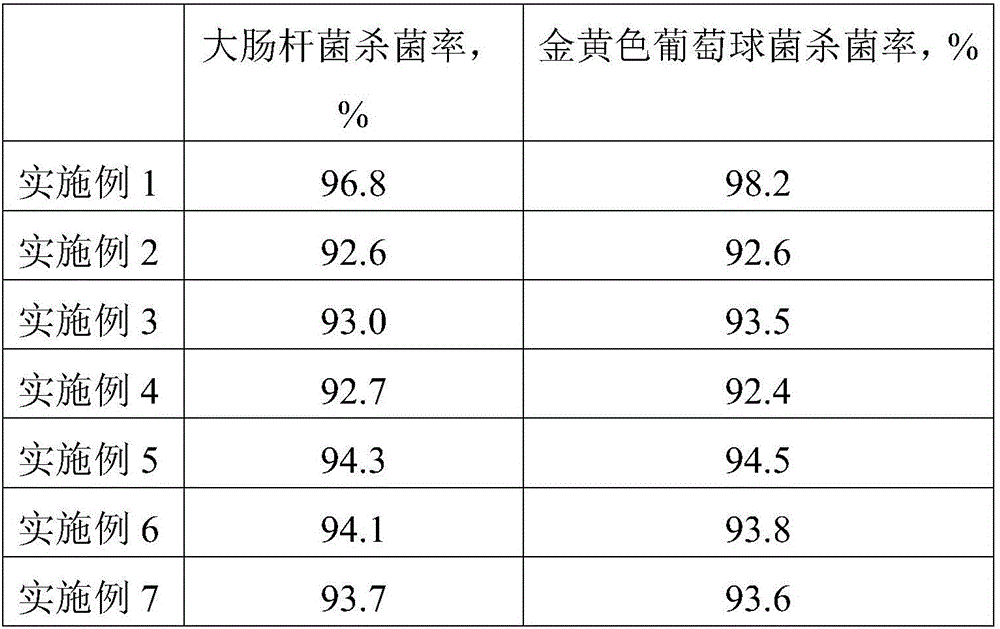

Examples

Embodiment 1

[0027] Antibacterial acrylic sheet material (parts by weight): 100 parts of methyl methacrylate, 0.4 part of dicumyl peroxide, 20 parts of aluminum hydroxide, 0.3 part of n-octanol, 3 parts of inorganic antibacterial agent, 0.6 part of antistatic agent

[0028] The inorganic antibacterial agent is obtained by uniformly stirring and mixing zirconium phosphate, magnesium titanate and magnesium niobate in a mass ratio of 1:1:1.

[0029] The antistatic agent consists of dioctadecylmethyl tertiary amine, octadecylmethyldihydroxyethylammonium bromide, and dodecyltrimethylammonium bromide in a mass ratio of 1:1:1. Stir to mix well.

[0030] Antibacterial acrylic sheet preparation, including the following steps:

[0031] (1) Mix methyl methacrylate and dicumyl peroxide evenly, then heat and polymerize in a water bath at 82°C for 30 minutes, and finally cool to room temperature to obtain a viscous plexiglass prepolymer;

[0032] (2) Mix organic glass prepolymer, aluminum hydroxide, n...

Embodiment 2

[0036] It is basically the same as Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing magnesium titanate and magnesium niobate at a mass ratio of 1:1. Obtain the antibacterial acrylic sheet material of embodiment 2.

Embodiment 3

[0038] It is basically the same as that of Example 1, except that the inorganic antibacterial agent is obtained by uniformly stirring and mixing zirconium phosphate and magnesium niobate at a mass ratio of 1:1. Obtain the antibacterial acrylic sheet material of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com