Biodegradable polylactic acid film and preparation method thereof

A polylactic acid and film technology, applied in the field of film products, can solve problems such as environmental hazards, white pollution, accumulation of plastic waste, etc., and achieve the effect of enhancing thermal insulation performance, less demanding, and improving strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

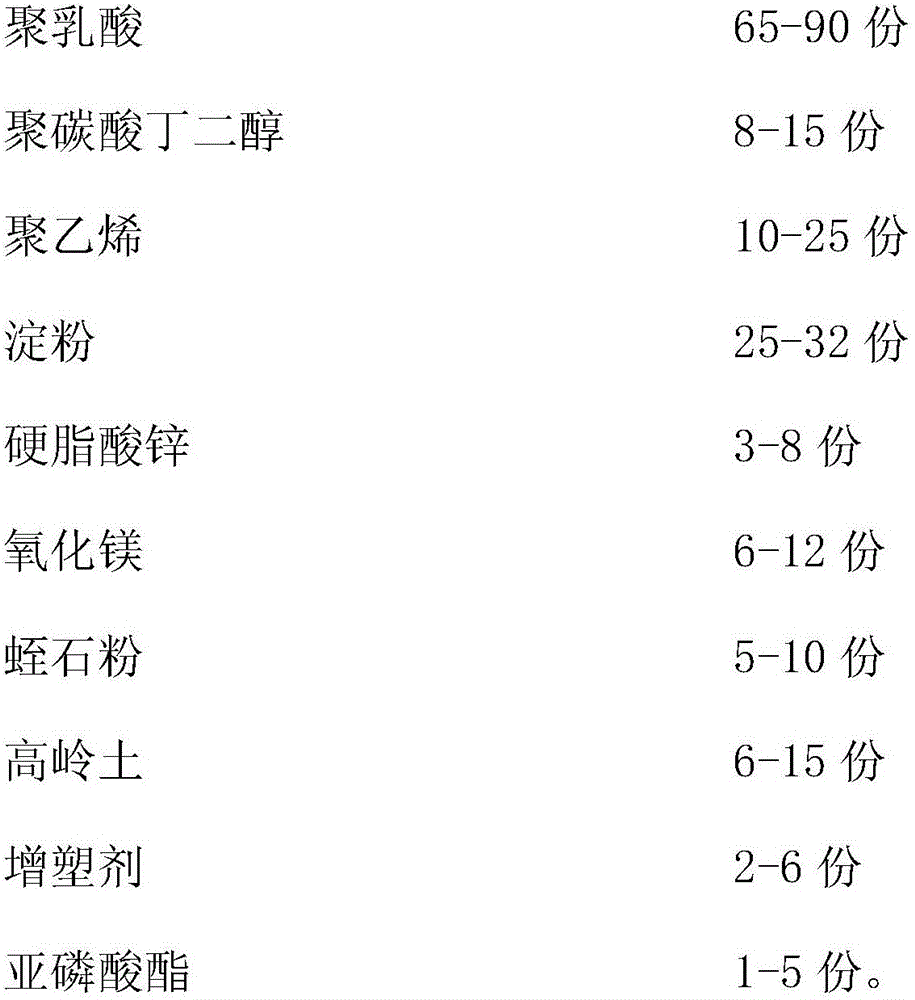

[0025] A biodegradable polylactic acid film is composed of the following raw materials by weight: 65 parts of polylactic acid, 8 parts of polybutylene carbonate, 10 parts of polyethylene, 25 parts of starch, 3 parts of zinc stearate, and 6 parts of magnesium oxide , 5 parts of vermiculite powder, 6 parts of kaolin, 2 parts of plasticizer, 1 part of phosphite; Wherein, starch is the mixture of corn starch, potato starch and tapioca starch, and the weight ratio of corn starch, potato starch and tapioca starch is 2 :1:1; the plasticizer is epoxidized soybean oil.

[0026] A preparation method of a biodegradable polylactic acid film, specifically comprising the following steps:

[0027] (1) take by weighing the raw material of corresponding weight portion respectively, polylactic acid, polybutylene carbonate, polyethylene, starch, zinc stearate, magnesium oxide, vermiculite powder, kaolin, plasticizer and phosphite are added to the mixing In the machine, the heating temperature i...

Embodiment 2

[0032] A biodegradable polylactic acid film is composed of the following raw materials by weight: 90 parts of polylactic acid, 15 parts of polybutylene carbonate, 25 parts of polyethylene, 32 parts of starch, 8 parts of zinc stearate, and 12 parts of magnesium oxide , 10 parts of vermiculite powder, 15 parts of kaolin, 6 parts of plasticizer, 5 parts of phosphite; Wherein, starch is the mixture of corn starch, potato starch and tapioca, and the weight ratio of corn starch, potato starch and tapioca is 2 :1:1; the plasticizer is epoxidized soybean oil.

[0033] A preparation method of a biodegradable polylactic acid film, specifically comprising the following steps:

[0034] (1) take by weighing the raw material of corresponding weight portion respectively, polylactic acid, polybutylene carbonate, polyethylene, starch, zinc stearate, magnesium oxide, vermiculite powder, kaolin, plasticizer and phosphite are added to the mixing In the machine, the heating temperature is 90°C, t...

Embodiment 3

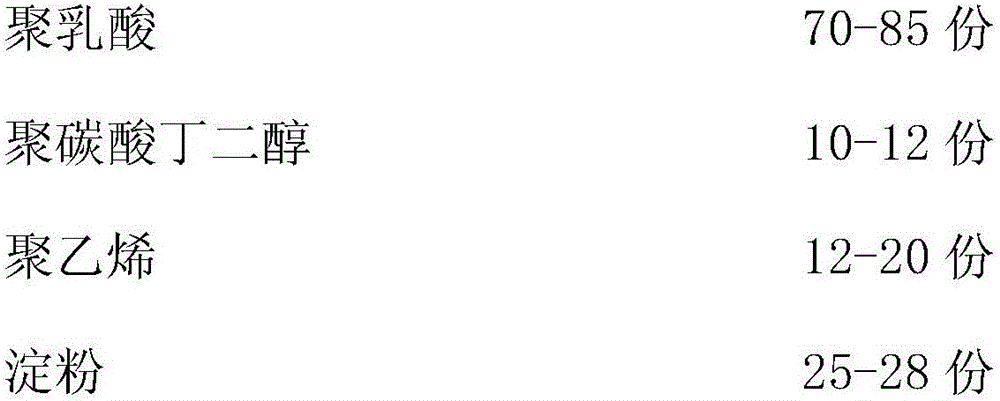

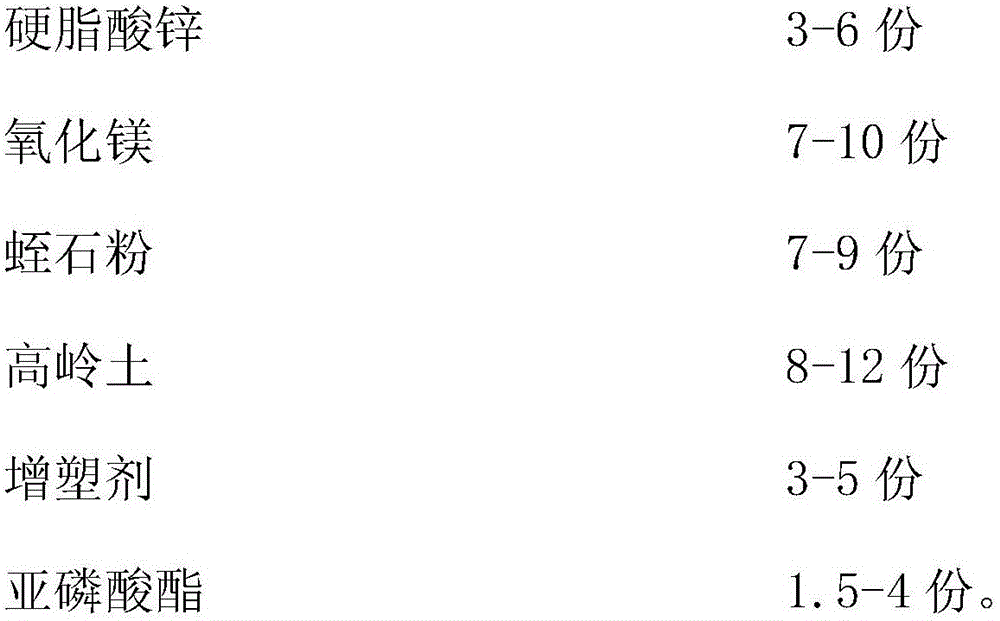

[0039] A biodegradable polylactic acid film is composed of the following raw materials by weight: 70 parts of polylactic acid, 10 parts of polybutylene carbonate, 12 parts of polyethylene, 25 parts of starch, 3 parts of zinc stearate, and 7 parts of magnesium oxide , 7 parts of vermiculite powder, 8 parts of kaolin, 3 parts of plasticizer, 1.5 parts of phosphite; Wherein, starch is the mixture of corn starch, potato starch and tapioca, and the weight ratio of corn starch, potato starch and tapioca is 2 :1:1; the plasticizer is epoxidized soybean oil.

[0040] A preparation method of a biodegradable polylactic acid film, specifically comprising the following steps:

[0041] (1) take by weighing the raw material of corresponding weight portion respectively, polylactic acid, polybutylene carbonate, polyethylene, starch, zinc stearate, magnesium oxide, vermiculite powder, kaolin, plasticizer and phosphite are added to the mixing In the machine, the heating temperature is 80°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com