Electronic gun chamber for electron beam smelting furnace inflated with argon

An electron beam smelting furnace and electron beam technology, applied in the direction of discharge tube electron guns, circuits, discharge tubes, etc., can solve the problems of unclear scanning trajectory of electron beams, affecting the quality of smelting ingots, affecting electron beams, etc., and achieve sufficient effective power Excellent performance, stable quality, clear track effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments will be further described in detail below in conjunction with the accompanying drawings.

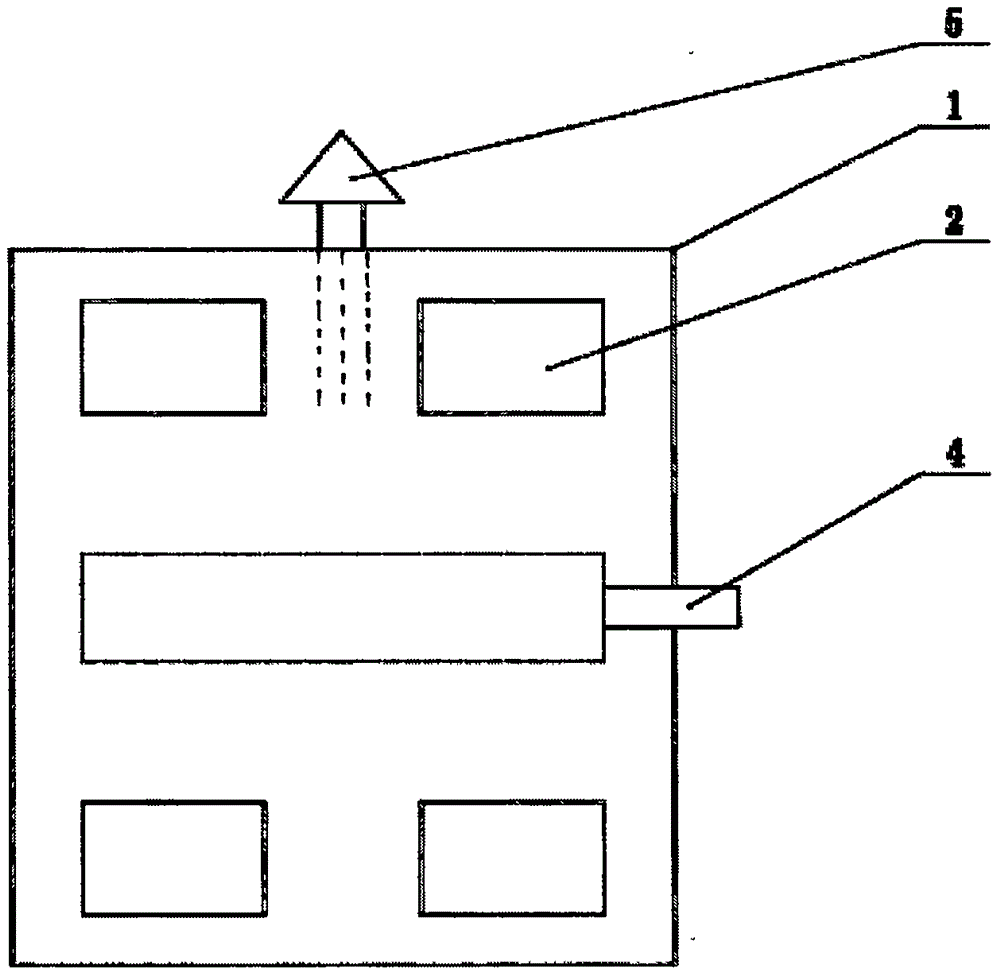

[0015] Such as figure 1 As shown, it is a schematic diagram of the internal structure of an electron gun chamber for an argon-filled electron beam melting furnace according to the present invention, and the electron beam furnace has a vertical cylinder structure. It includes an electron beam gun chamber 1, a focusing coil 2, an argon gas flow control valve 4, and an electron beam 5. The dashed box on the left side of the argon gas flow control valve 4 represents the schematic diagram of the argon flow; the dotted line at the bottom of the electron beam 5 represents the electron beam A sign of flow. The present invention installs the argon gas flow control valve 4 in the gun chamber 1, fills the electron beam gun chamber 1 with argon gas, moderately or matches the flow rate, and the argon gas is ionized to generate positive charges, thereby achieving stable electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com