High-density carboxyl-modified magnetic microspheres and preparation method thereof

A technology of magnetic microspheres and carboxyl modification, which is applied in the field of high-density carboxyl-modified magnetic microspheres and its preparation. It can solve the problems of less bioligand coating, low carboxyl density, and low carboxyl activity. The effect of large, high carboxyl group density, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) In the air, 7g FeCl 2 4H 2 O was added to 50 mL of deionized water to obtain a concentration of 0.14 g / mL of FeCl 2 aqueous solution. to 50mL FeCl 2 Add 30 mL of ammonia water to the aqueous solution, and after stirring for 45 minutes, the color gradually turns light green, then dark green, and finally black;

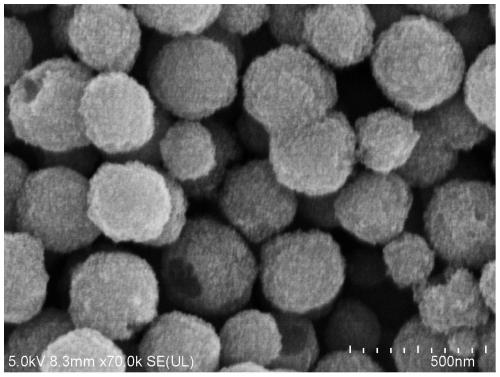

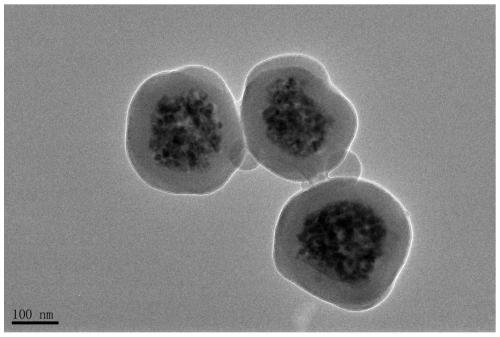

[0041] (2) Add 1.1 g of oleic acid to step (1), mix evenly, place the mixed solution in a closed reaction kettle, heat and react at 110° C. for 4 hours, then alternately wash once with deionized water and ethanol, Disperse in n-hexane after magnetic separation to obtain the black paramagnetic nano-Fe coated with oleic acid3 o 4 1;

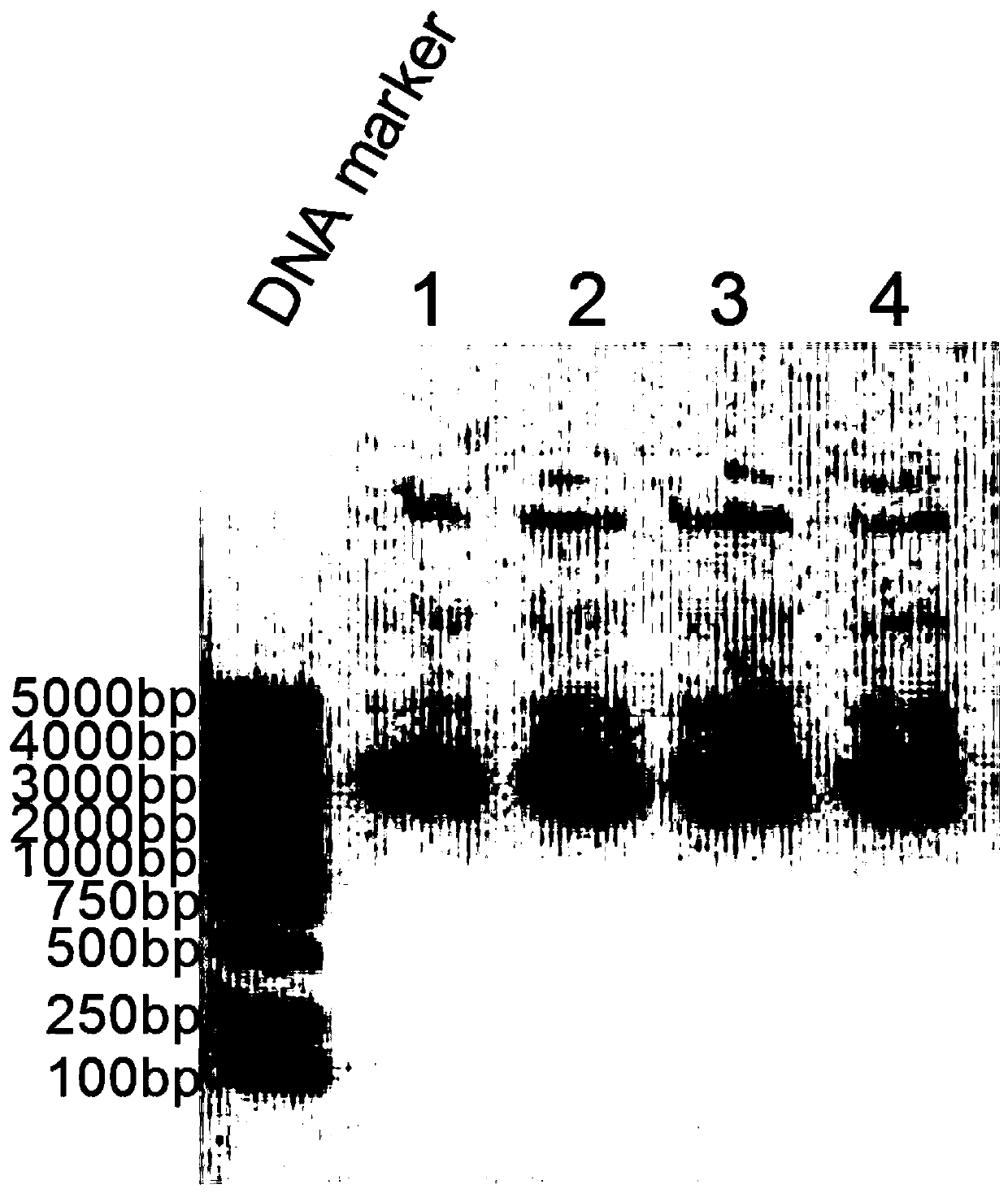

[0042] (3) to the paramagnetic nano-Fe containing 10mg oleic acid 3 o 4 1 solution, add 125 mg ammonia water, 30 mg tetraethyl orthosilicate and 30 mg (3-aminopropyl) triethoxysilane, react for 1 day, perform magnetic separation, and alternately wash twice with ethanol and water to obtain amino Modified silica-coated mag...

Embodiment 2

[0045] (1) In the air, 10g FeCl 2 ·H 2 O was added to 100 mL of deionized water to obtain a concentration of 0.10 g / mL of FeCl 2 aqueous solution. to 100mLFeCl 2 ·H 2 Add 20 mL of ammonia water to the O aqueous solution, and after stirring for 60 minutes, the color gradually turns light green, then dark green, and finally black;

[0046] (2) Add 1 g of oleic acid to step (1), mix evenly, place the mixed solution in a closed reaction kettle, heat and react at 60° C. for 5 hours, then alternately wash twice with deionized water and ethanol, Disperse in octane after magnetic separation to obtain the black paramagnetic nano Fe coated with oleic acid 3 o 4 2;

[0047] (3) to the paramagnetic nano-Fe containing 10mg oleic acid 3 o 4 Add 250 mg of ammonia water, 20 mg of tetraethyl orthosilicate and 10 mg of (3-aminopropyl) triethoxysilane to the solution of 2, conduct magnetic separation after 2 days of reaction, and alternately wash twice with ethanol and water to obtain...

Embodiment 3

[0050] (1) In the air, 50gFeCl 2 ·H 2 O was added to 100 mL of deionized water to obtain a concentration of 0.50 g / mL of FeCl 2 aqueous solution. to 100mLFeCl 2 ·H 2 Add 50 mL of ammonia water to the O aqueous solution, and after stirring for 90 minutes, the color gradually turns light green, then dark green, and finally black;

[0051] (2) Add 5g of oleic acid to step (1), mix evenly, place the mixed solution in a closed reaction kettle, heat and react at 130°C for 3 hours, then alternately wash twice with deionized water and ethanol, Disperse in n-octane after magnetic separation to obtain the black paramagnetic nano-Fe coated with oleic acid 3 o 4 3.

[0052] (3) to the paramagnetic nano-Fe containing 10mg oleic acid 3 o 4 Add 125 mg of ammonia water, 40 mg of tetraethyl orthosilicate and 5 mg of (3-aminopropyl) triethoxysilane to the solution of 3, conduct magnetic separation after 3 days of reaction, and alternately wash twice with ethanol and water to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com