Substrate surface microfluidics method

A substrate surface, microfluidic technology, applied in the process of producing decorative surface effects, chemical instruments and methods, microstructure technology, etc., can solve the problems of difficult to achieve precise control of liquids, development bottlenecks, etc. The effect of convenience, overcoming harsh requirements, and breaking through the bottleneck of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, see figure 1 , a method for substrate surface microfluidics, comprising the steps of:

[0039] a. Select a silicon wafer as the substrate, and use hydrophobic substances as modifiers to modify the surface of the substrate. The specific steps are as follows: first, the silicon wafer is ultrasonically treated with chloroform, acetone, ethanol, and water for 10 minutes, and then blown dry with nitrogen for later use; prepare chloroform : The molar ratio of n-ethane is 40ml of the mixed solution of 3:7, then add OTS 10ul, after stirring evenly, the modifier is obtained, put the spare silicon substrate after the above treatment into the modifier, and let it stand in the fume hood for 5 -7 hours, after taking the silicon wafer out of the modifier, rinse the silicon wafer with chloroform, acetone, and ethanol respectively, blow dry the silicon wafer with nitrogen, and then bake the silicon wafer at 80°C for 10 minutes. A modified surface layer is formed on th...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

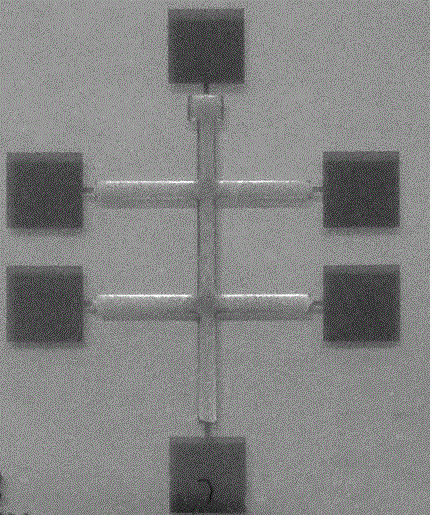

[0045] In this example, see figure 2 , a method for substrate surface microfluidics, comprising the steps of:

[0046] a. Select glass as the substrate, use hydrophobic substances as modifiers, and modify the surface of the substrate, specifically: first, ultrasonically treat the glass with chloroform, acetone, ethanol, and water for 10 minutes, and then dry it with nitrogen for later use; prepare chloroform: Add 40ml of a mixed solution with a molar ratio of ethane of 3:7, add OTS 10ul, stir well to obtain a modifier, put the spare glass substrate after the above treatment into the modifier, and let it stand in a fume hood for 5-7 hours , after taking the glass out of the modifier, rinse the glass with chloroform, acetone, and ethanol respectively, blow the glass dry with nitrogen, and then bake the silicon wafer at 80°C for 10 minutes to form a modified surface layer on the glass surface. ...

Embodiment 3

[0051] This embodiment is basically the same as the previous embodiment, and the special features are:

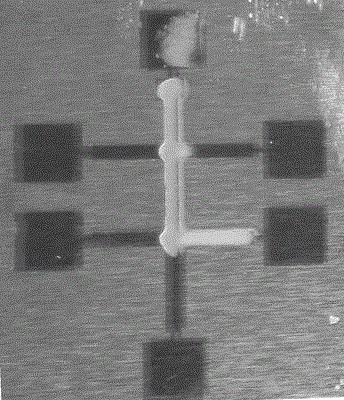

[0052] In this example, see image 3 , a method for substrate surface microfluidics, comprising the steps of:

[0053] a. This step is identical with embodiment two;

[0054] B. this step is identical with embodiment two;

[0055] c. Utilize the method of electric heating, select the electric current to control the heating method, through the electric selection area, make the part of the gold pattern on the hydrophobic substrate be connected with the external circuit, form the external circuit system, and apply it to the hydrophobic substrate by controlling the external circuit system The current of the gold pattern on the hydrophobic substrate is heated locally, and the other regions of the gold pattern on the hydrophobic substrate that are not energized are not heated by electricity and have a lower temperature. The local temperature change of the gold pattern is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com