Environment-friendly bowling shoe vamp leather material

A technology of bowling ball and shoe upper leather, applied in footwear, applications, clothing, etc., can solve the problems of smelly feet and insufficient air permeability, and achieve the effect of durable antibacterial, good air permeability, comfortable and beautiful wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

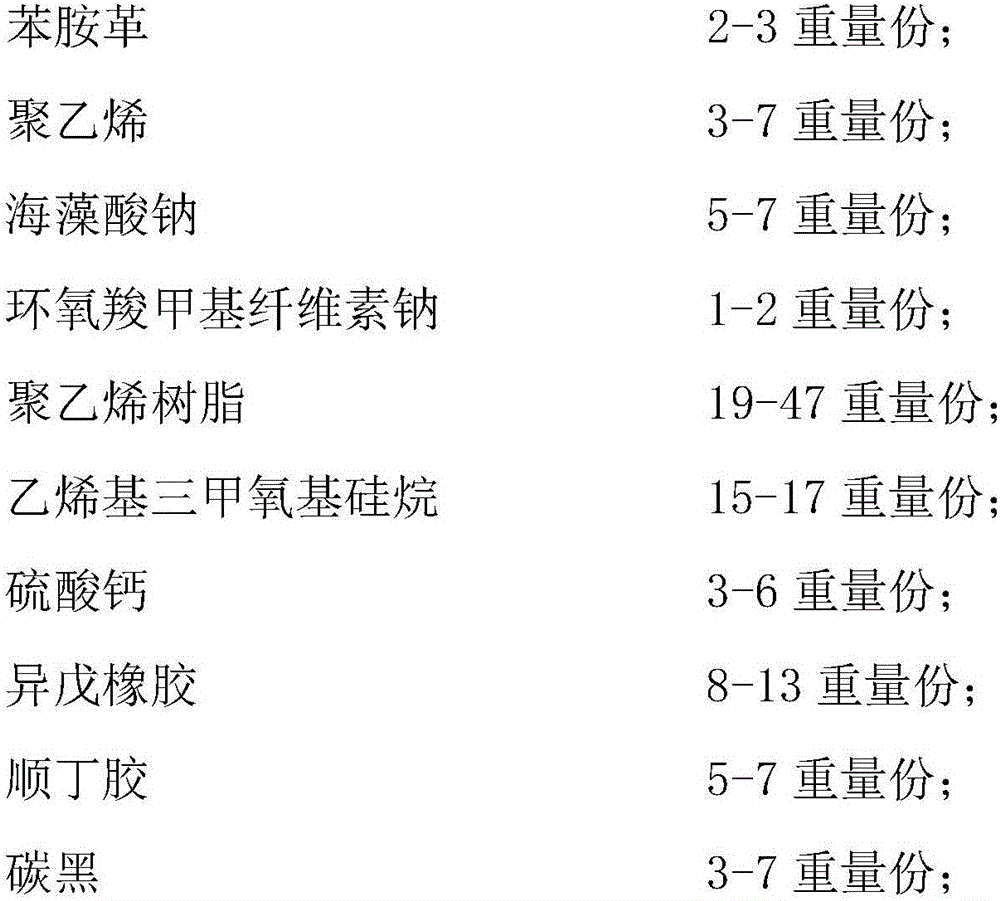

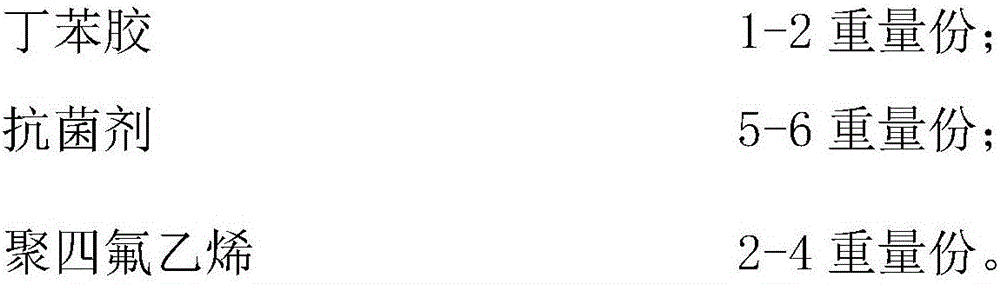

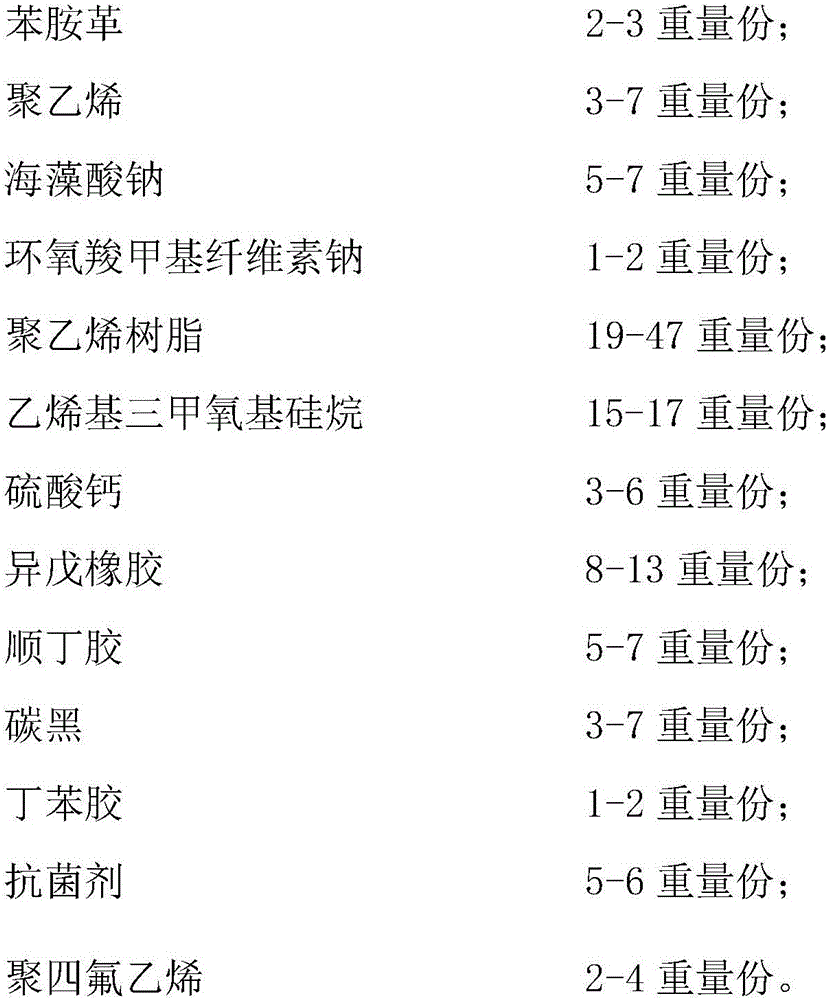

[0019] The invention provides a technical solution: an environment-friendly bowling shoe upper leather material, which is made of the following raw materials in parts by weight:

[0020]

[0021] Aniline leather is a kind of leather made by selecting leather with no damage on the surface and uniform grain surface in the hides that have been made into leather, and then lightly finishing with CX dyeing water or a small amount of color paste and resin. Aniline leather The original natural pattern of the animal skin is retained, the leather is soft and plump, the air permeability is good, the color is bright and pure, the antibacterial agent is one or more of zinc oxide, copper oxide, ammonium dihydrogen phosphate and lithium carbonate, and the anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com