Modified white graphene composite anticorrosive paint and preparing method thereof

A technology of white graphene and anti-corrosion coating, applied in the field of materials, can solve the problems of easy failure of anti-corrosion coating and loss of anti-corrosion effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

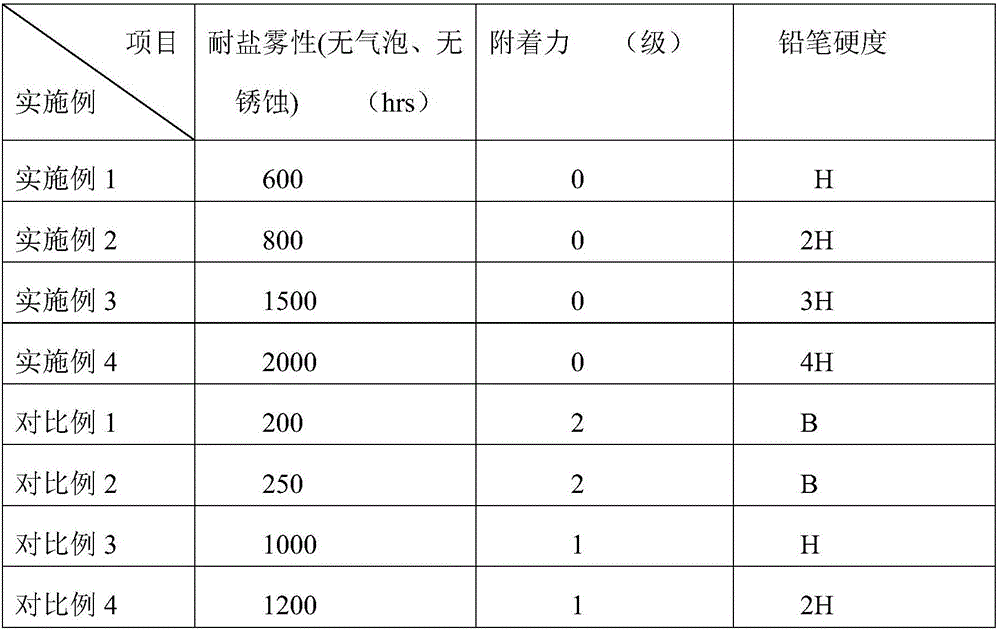

Examples

Embodiment 1

[0025] Step 1) Preparation of modified white graphene: soak 5-10 layers of white graphene with 0.1% long-chain borane aqueous solution for 24 hours to obtain long-chain borane-modified white graphene solution.

[0026] Step 2) Dissolve 43.9 parts of alkyd resin, 12 parts of calcium carbonate, 7.5 parts of titanium dioxide, 0.5 parts of carbon black, 1 part of BYK UMEN, 0.1 part of BYK 065 in 25 parts of xylene / n-butanol / ethyl acetate mixed solvent Stir uniformly in medium to obtain a matrix resin solution; 5 parts of modified white graphene dispersions prepared in step 1) are stirred evenly with the above-mentioned matrix resin solution to obtain a high-performance alkyd resin anticorrosive coating of composite modified white graphene.

Embodiment 2

[0028] Step 1) Preparation of modified white graphene: soak 5-10 layers of white graphene with 0.1% oleylamine aqueous solution for 24 hours to obtain oleylamine-modified white graphene solution.

[0029] Step 2) dissolve 33 parts of epoxy-modified acrylic resin, 12 parts of barium sulfate, 8 parts of red iron oxide, 1.5 parts of Tego 740W, 0.5 parts of Tego 810 in 30 parts of water and stir evenly to obtain matrix resin; 10 parts of the modified white graphene dispersion liquid are stirred evenly with the above-mentioned matrix resin liquid, and the high-performance epoxy-modified acrylic resin anticorrosion coating of composite modified white graphene is obtained.

Embodiment 3

[0031] Step 1) Preparation of modified white graphene: soak 5-10 layers of white graphene with 0.1% sodium dodecylsulfonate for 24 hours to obtain a long-chain borane-modified white graphene solution.

[0032] Step 2) Dissolve 43.9 parts of epoxy resin, 12 parts of talc powder, 8 parts of iron oxide red, 1 part of BYK P-104, 0.1 part of BYK066N in 20 parts of xylene / n-butanol / ethyl acetate mixed solvent and stir well 15 parts of modified white graphene dispersion liquid and epoxy resin solution that step 1) make are stirred evenly; Add 10 parts of diethylenetriamine again, stir and mix, promptly make the high performance of compound modified white graphene Epoxy resin anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com