Treatment method and device of electrolytic aluminum carbon slag

A processing device and processing method technology, applied in the field of aluminum electrolysis, can solve the problems of raw material waste, environmental pollution, environmental pollution, etc., and achieve the effects of long service life and high electrolyte quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

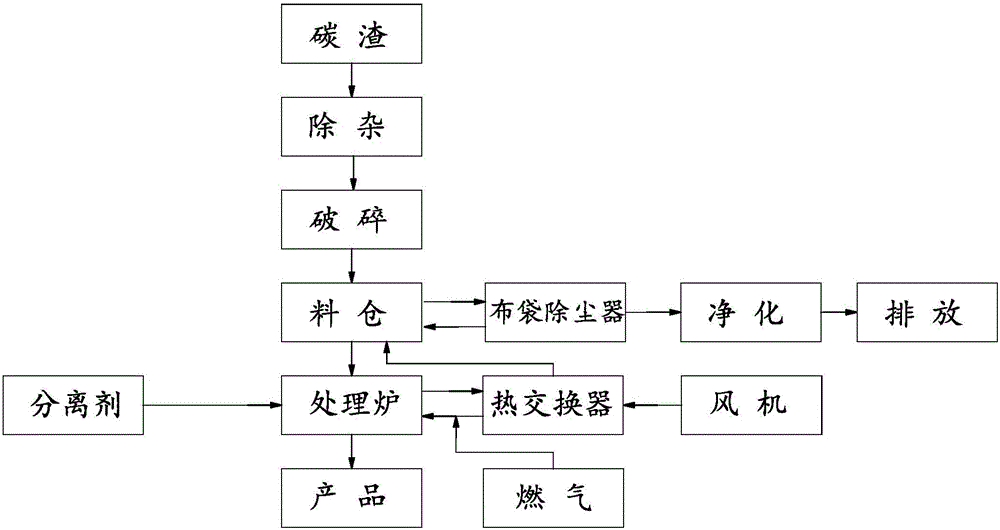

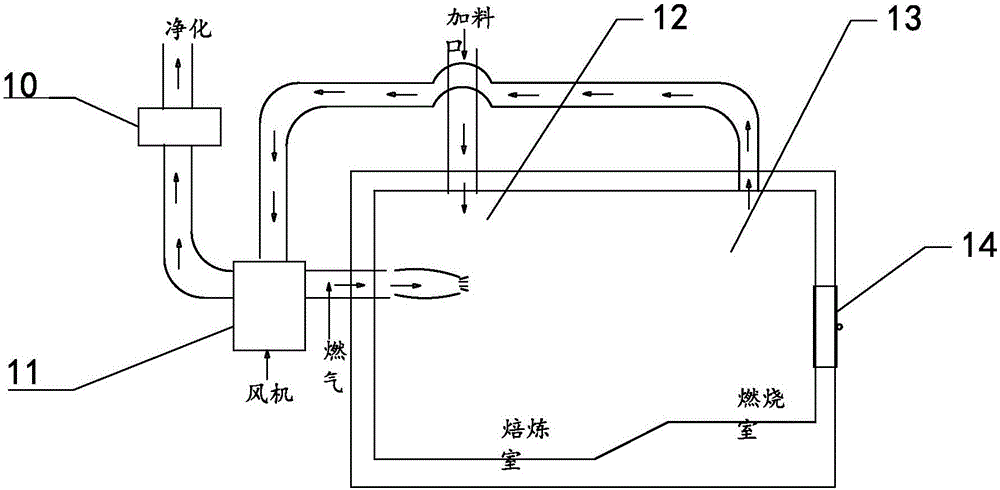

[0032] Such as figure 1 As shown, the solid impurities and iron in the carbon slag are first removed; then the carbon slag is crushed to a maximum particle size ≤ 5mm; the carbon slag is preheated to 100-120°C, and then added to the processing device, which includes a roasting chamber and a combustion chamber , the roasting chamber is heated to 1000-1100°C, the electrolyte in the carbon slag is separated from the carbon slag, and a separating agent is added to separate the electrolyte from the carbon slag; the separated carbon slag enters the combustion chamber and is burned; The exchange chamber exchanges heat with the air, and the heated air enters the silo to preheat the carbon slag; the flue gas from the heat exchanger enters the bag filter, the bag filter collects dust and enters the silo, and the flue gas from the bag filter Discharge after purification is qualified.

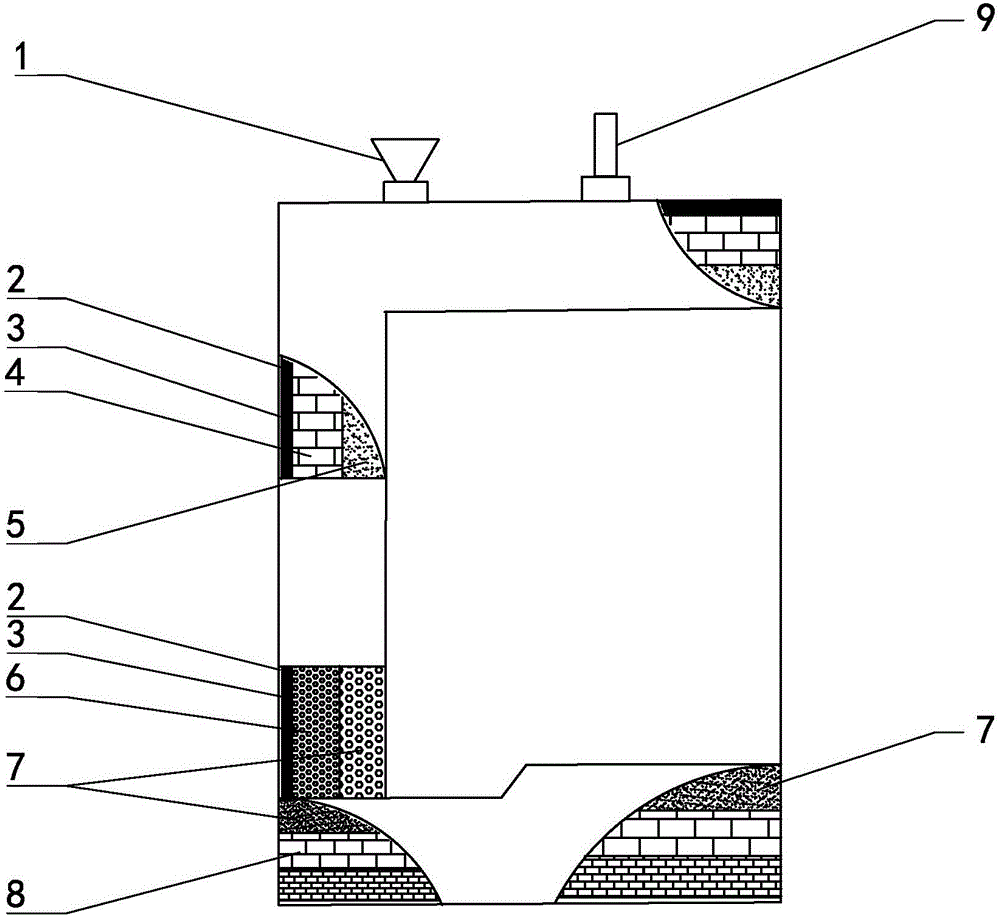

[0033] Such as figure 2 , 3 As shown, a processing device for electrolytic aluminum carbon slag inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com