Method for determining multi-component resultant in multivariant anode material precursor based on EDTA back titration-automatic titration method

A positive electrode material and automatic titration technology, which is applied in the direction of chemical analysis by titration, analysis by making materials undergo chemical reactions, and material analysis by observing the impact on chemical indicators, etc., which can solve the difficulties in judging the end point and inaccurate determination. Accurate, time-consuming and labor-intensive problems, to achieve the effect of improving the level of automatic detection and reliability, high precision and accuracy, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

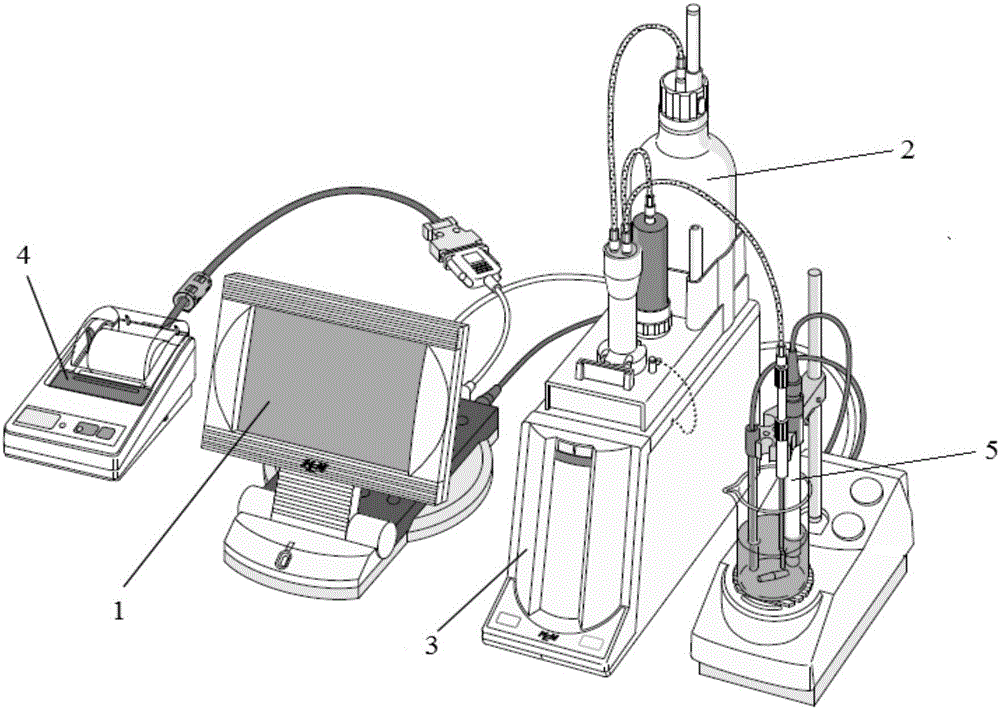

Method used

Image

Examples

Embodiment 1

[0058] (1) Sample dissolution: Accurately weigh ~1.0000g (1.0001g) nickel-cobalt-manganese ternary material precursor type 111 sample (abbreviated as 1# sample), add 15mL 1+1 hydrochloric acid, heat and decompose on the electric furnace, and wait for the test After the material is completely dissolved, cool down, transfer to a 250mL volumetric flask and dilute to the mark with ultrapure water to obtain the sample solution.

[0059] (2) Excess EDTA complexed ternary compound amount: accurately pipette 25mL of the above sample solution into a plastic cup for an automatic titration device, add 2mL of 5% ascorbic acid solution, 30mL of 0.05M EDTA-2Na solution, 1mL of 1+1 hydrochloric acid, 20-30mL boric acid-sodium borate buffer solution, adjust the pH to 9.0, record the volume of EDTA-2Na as V 1 .

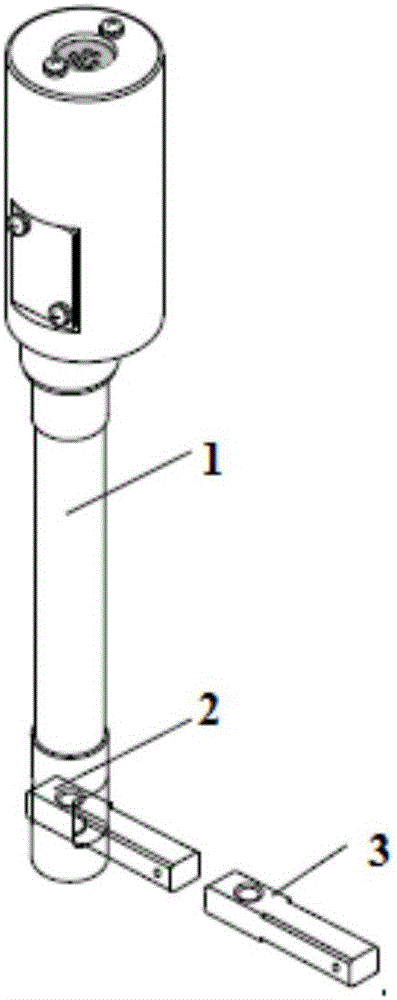

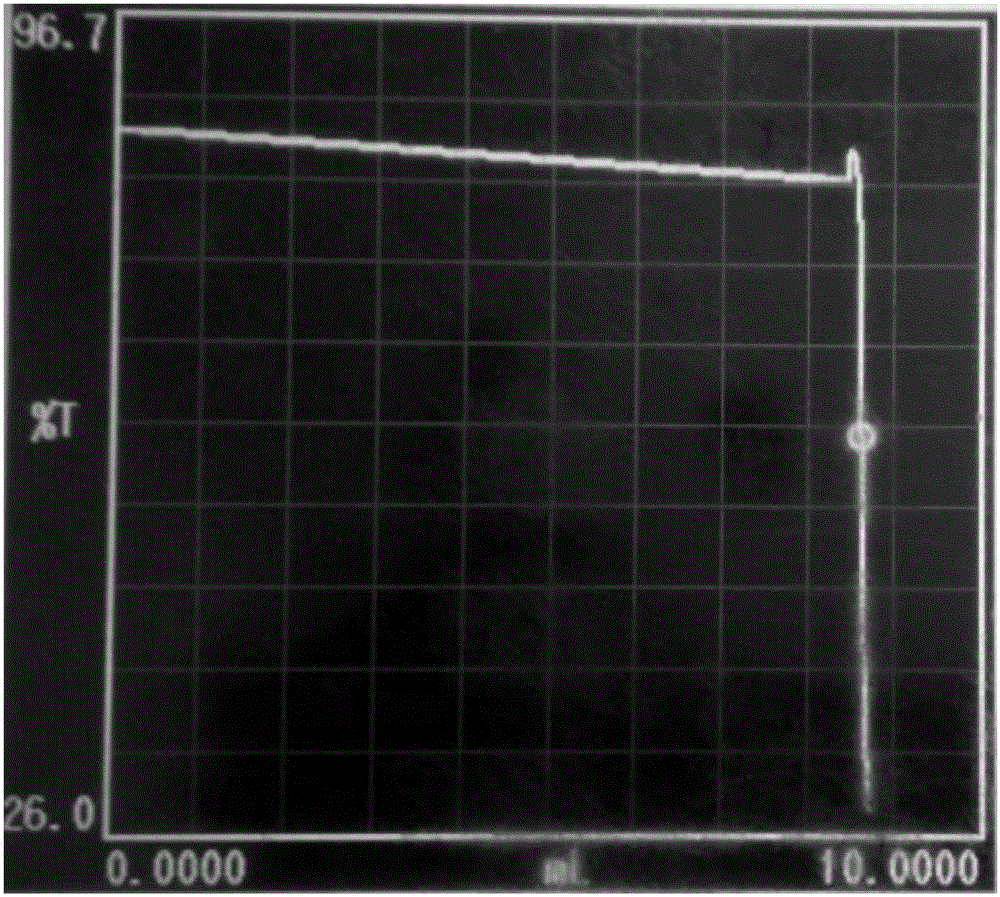

[0060] (3) Back titration: Use ultrapure water to adjust the volume of the sample solution in step (2) to 160mL so that it is completely submerged in the effective part of the sensin...

Embodiment 2

[0066] (1) Sample dissolution: Accurately weigh ~1.0000g (1.0001g) nickel-cobalt-manganese ternary material precursor type 523 sample (referred to as 2# sample), add 15mL 1+1 hydrochloric acid, put it on the electric furnace and heat it to decompose, and wait for the test After the material is completely dissolved, cool down, transfer to a 250mL volumetric flask and dilute to the mark with ultrapure water to obtain the sample solution.

[0067] (2) Excess EDTA complexed ternary compound amount: accurately pipette 25mL of the above sample solution into a plastic cup for an automatic titration device, add 2mL of 5% ascorbic acid solution, 30mL of 0.05M EDTA-2Na solution, 1mL of 1+1 hydrochloric acid, 20-30mL boric acid-sodium borate buffer solution, adjust the pH to 9.0, record the volume of EDTA-2Na as V1.

[0068] (3) Back titration: Use ultrapure water to adjust the volume of the sample solution in step (2) to 160mL so that it is completely submerged in the effective part of ...

Embodiment 3

[0074] (1) Sample dissolution: Accurately weigh ~1.0000g (1.0001g) nickel-cobalt-manganese ternary material precursor type 622 sample (abbreviated as 3# sample), add 15mL 1+1 hydrochloric acid, heat and decompose on the electric furnace, and wait for the test After the material is completely dissolved, cool down, transfer to a 250mL volumetric flask and dilute to the mark with ultrapure water to obtain the sample solution.

[0075] (2) Excess EDTA complexed ternary compound amount: accurately pipette 25mL of the above sample solution into a plastic cup for an automatic titration device, add 2mL of 5% ascorbic acid solution, 30mL of 0.05M EDTA-2Na solution, 1mL of 1+1 hydrochloric acid, 20-30mL boric acid-sodium borate buffer solution, adjust the pH to 9.0, record the volume of EDTA-2Na as V1.

[0076] (3) Back titration: Use ultrapure water to adjust the volume of the sample solution in step (2) to 160mL so that it is completely submerged in the effective part of the sensing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com