Manufacturing method of dry fruit powder of medlar

A manufacturing method and technology of dried wolfberry, applied in the direction of food science and other directions, can solve the problems of long residence time of wolfberry fruit powder, easy moisture absorption, nutrition loss of wolfberry, etc., so as to solve the problem of pesticide residues and pathogenic bacteria residues, and the production cycle is short. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

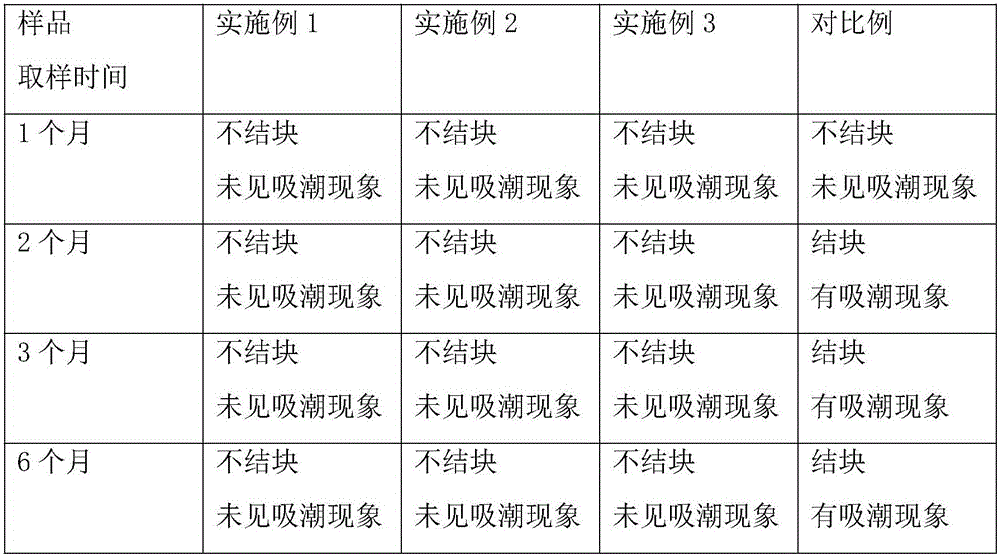

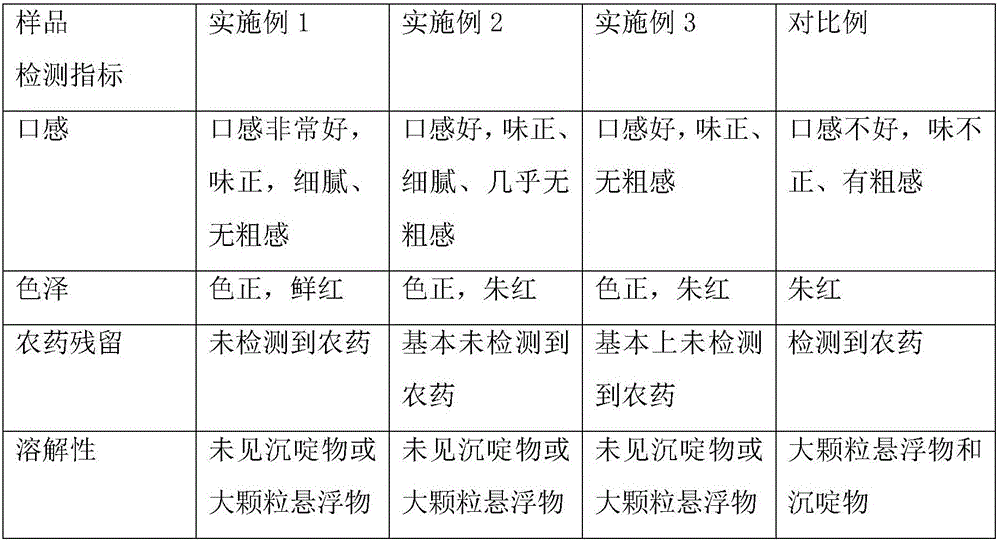

Examples

Embodiment 1

[0038] The manufacturing process of embodiment 1 wolfberry dried fruit powder

[0039] The manufacturing process of wolfberry dried fruit powder, its operation steps are as follows:

[0040] (1) The picked fresh Lycium barbarum fruit with fruit pedicles is washed with clean water, then rinsed with clean water, drained, and then put into 0.8% ClO 2 Soak in the solution for 10 minutes;

[0041] (2) After soaking, rinse with clean water, drain, put into 1% sodium percarbonate solution and soak for 10 minutes, then rinse with purified water, remove fruit pedicles, rinse with normal saline, rinse with purified water and drain moisture;

[0042] (3) Pre-freeze the drained wolfberry fresh fruit, the freezing temperature is set to -45°C, the cooling rate is 1.5-2°C / min, and the pre-freezing time is 2-3h;

[0043] (4) Vacuum freeze-dry the pre-frozen wolfberry fresh fruit, keep the vacuum at 35Pa, keep the temperature of the cold trap at -50°C, raise the drying temperat...

Embodiment 2

[0046] Embodiment 2 Lycium barbarum dried fruit powdering process

[0047] The process of powdering dried wolfberry fruit, the operation steps are as follows:

[0048] (1) The picked fresh Lycium barbarum fruit with fruit pedicles is washed with clear water, then rinsed with clear water, drained, and then put into 1% ClO2 solution for soaking for 5 minutes;

[0049] (2) After soaking, rinse with clean water, drain, put into 1% sodium percarbonate solution and soak for 8 minutes, then rinse with purified water, remove the pedicle, rinse with normal saline, rinse with purified water and drain the water ;

[0050] (3) Pre-freeze the drained wolfberry fresh fruit, the freezing temperature is set to -45°C, the cooling rate is 1.5°C / min, and the pre-freezing time is 3h;

[0051] (4) Vacuum freeze-dry the pre-frozen wolfberry fresh fruit, keep the vacuum at 30-40Pa, keep the cold trap temperature at -50°C, raise the drying temperature from -45°C to -30°C, keep it warm f...

Embodiment 3

[0054] The manufacturing process of embodiment 3 wolfberry dried fruit powder

[0055] The manufacturing process of wolfberry dried fruit powder, its operation steps are as follows:

[0056] (1) The picked fresh Lycium barbarum fruit with pedicles is rinsed with clean water, then rinsed with clean water, drained, and then put into 0.5% ClO 2 Soak in solution for 10 minutes;

[0057] (2) After soaking, rinse with clean water, drain, put into 1% sodium percarbonate solution and soak for 15 minutes, then rinse with purified water, remove the pedicle, rinse with normal saline, rinse with purified water and drain the water ;

[0058] (3) Pre-freeze the drained wolfberry fresh fruit, the freezing temperature is set to -45°C, the cooling rate is 2°C / min, and the pre-freezing time is 2h;

[0059] (4) Vacuum freeze-dry the pre-frozen wolfberry fresh fruit, keep the vacuum at 30-40Pa, keep the cold trap temperature at -50°C, raise the drying temperature from -45°C to -30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com