Method for improving sensory quality of reconstituted tobaccos through biotransformation

A technology of reconstituted tobacco leaves and biotransformation, applied in the field of tobacco industry, can solve the problems of reducing irritation, achieve the effects of reducing irritation, improving sensory quality, and reducing green miscellaneous gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

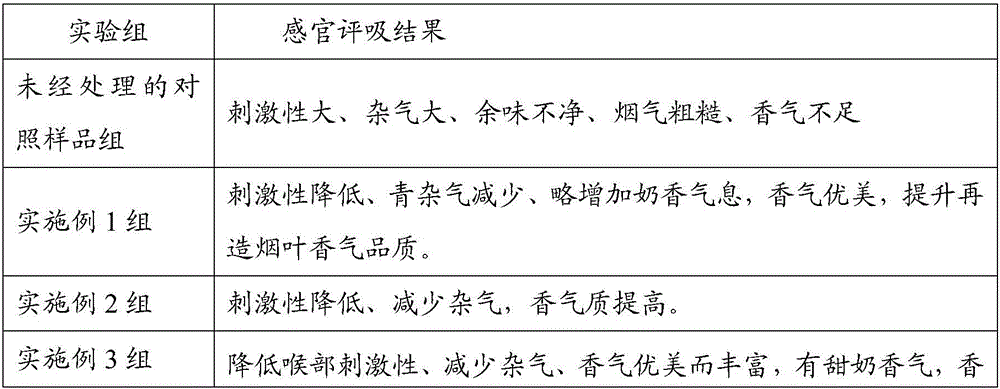

Examples

Embodiment 1

[0020] A method for biotransforming reconstituted tobacco leaves for improving organoleptic quality, comprising the following steps:

[0021] (1) Strain activation: Bacillus methylotrophicus (VJ4-1) was inoculated on the potato dextrose agar slant medium, and the slant culture was obtained after static culture at 28°C and pH 5 for 28 hours, and then inoculated into the seeds The culture medium was shaken for 12 hours at 28°C with a rotational speed of 115rpm / min, and the seed culture solution was obtained after two consecutive transfers;

[0022] The slant medium: 200 mL / L of potato infusion, 20 g / L of glucose, and 13 g / L of agar. Described seed medium: maltose 50g / L, peptone 10g / L, sodium chloride 5g / L.

[0023] (2) Composite biotransformation pretreatment: in the extraction process of reconstituted tobacco leaves, the seed culture solution described in step 1) is inoculated into the reconstituted tobacco aqueous solution at a mass ratio of 5%, and 0.18% of the mass ratio of...

Embodiment 2

[0026] A method for biotransforming reconstituted tobacco leaves for improving organoleptic quality, comprising the following steps:

[0027] (1) Strain activation: Bacillus methylotrophicus (VJ4-1) was inoculated on the potato dextrose agar slant medium, and the slant culture was obtained after static culture at 30°C and pH5.5 for 36 hours, and then inoculated Transfer to the seed medium, shake and cultivate at 30°C and 120rpm / min for 18 hours, and transfer 3 times in succession to obtain the seed culture solution;

[0028] The slant medium: 200 mL / L of potato infusion, 20 g / L of glucose, and 13 g / L of agar. Described seed medium: maltose 50g / L, peptone 10g / L, sodium chloride 5g / L.

[0029] (2) Composite biotransformation pretreatment: in the extraction process of reconstituted tobacco leaves, the seed culture solution described in step 1) is inoculated into the reconstituted tobacco leaf aqueous solution by mass ratio of 9%, and 0.3% of the mass ratio of reconstituted tobacco...

Embodiment 3

[0032] A method for biotransforming reconstituted tobacco leaves for improving organoleptic quality, comprising the following steps:

[0033] (1) Strain activation: Bacillus methylotrophicus (VJ4-1) was inoculated on the potato dextrose agar slant medium, and the slant culture was obtained after static culture at 32°C and pH 6 for 72 hours, and then inoculated into the seeds The culture medium was shaken for 30 hours at 32°C with a rotational speed of 125rpm / min, and the seed culture solution was obtained after two consecutive transfers;

[0034] The slant medium: 200 mL / L of potato infusion, 20 g / L of glucose, and 13 g / L of agar. Described seed medium: maltose 50g / L, peptone 10g / L, sodium chloride 5g / L.

[0035] (2) Composite biotransformation pretreatment: in the extraction process of reconstituted tobacco leaves, the seed culture solution described in step 1) is inoculated into the reconstituted tobacco leaf aqueous solution by mass ratio of 12%, and 0.25% of the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com