Makeup removing lotion, wet wipe containing makeup removing lotion and preparation method of wet wipe

A technology of makeup remover milk and wet wipes, which is applied in the field of chemical daily necessities, can solve the problems of unhygienic use, cumbersome procedures of makeup remover water and makeup remover oil, and difficult cleaning, etc., and achieve the effect of easy portability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment is the preparation of cleansing milk.

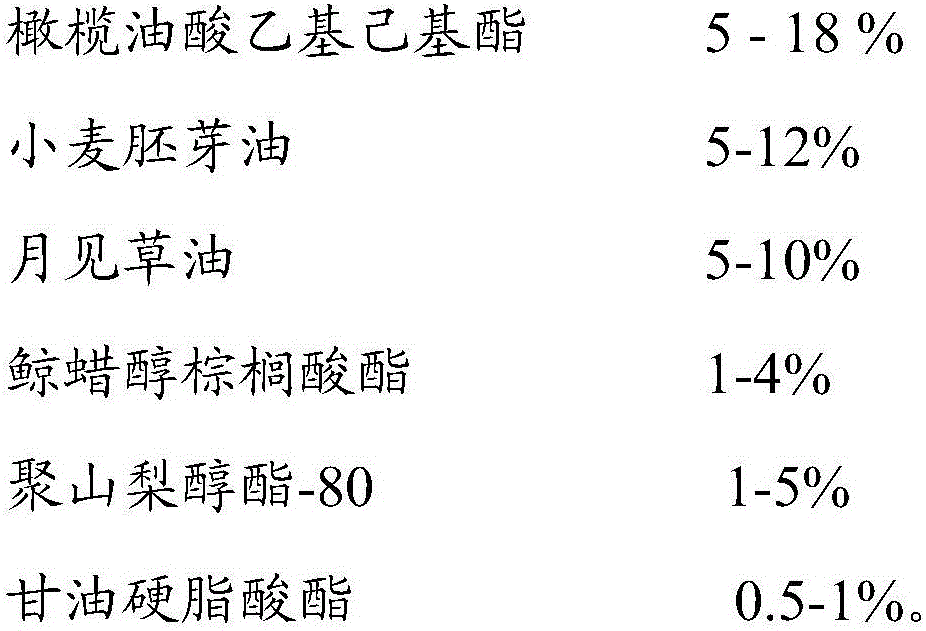

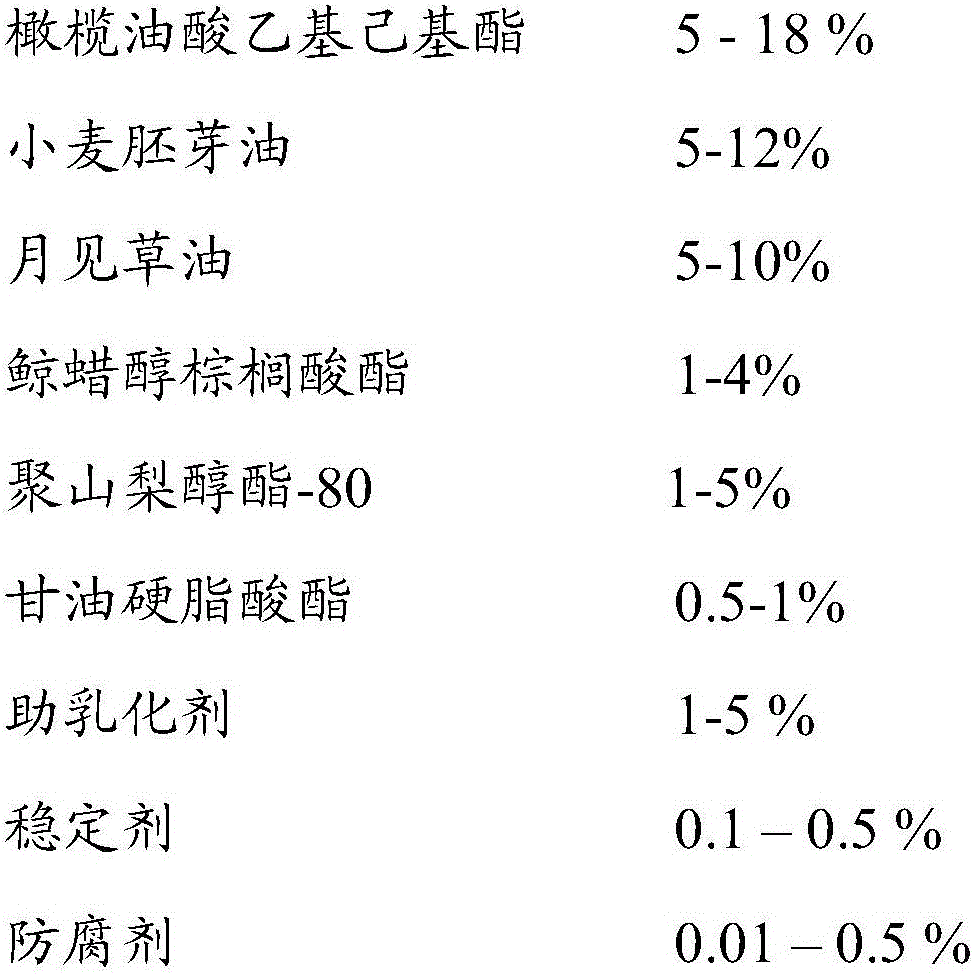

[0043] 1. Makeup remover formula

[0044] raw material name parts by weight Ethylhexyl Olivate 15 Wheat germ oil 5 evening primrose oil 5 Cetyl Palmitate 3 Polysorbate-80 2 Glyceryl Stearate 2 co-emulsifier 2 stabilizer 0.2 preservative 0.45 water 67.35 non-woven fabric _

[0045] 2. Production process

[0046] S11: In a sterile environment, mix ethylhexyl olive oil, wheat germ oil, evening primrose oil, cetyl palmitate, polysorbate-80, glyceryl stearate, and co-emulsifier Evenly, stir and heat at 80°C for 30 minutes to obtain solution A11;

[0047] S12: In a sterile environment at 80°C, add the stabilizer to water, stir at a stirring speed of 200 rpm for 20 minutes, and then stir at a stirring speed of 6000 rpm for 5 minutes to obtain a solution B11;

[0048] S13: A11 and B11 were mixed and stirred at a stirring speed of 300 rpm f...

Embodiment 2

[0054] 1. Formula of makeup remover wipes

[0055]

[0056]

[0057] 2. Production process

[0058] S31: Weigh each component compound according to the above mass.

[0059] S32: Under sterile conditions, paraffin, cyclopentasiloxane, squalane, lauryl olive oil, steareth-21, glyceryl stearate, PEG- 4 Olivate was mixed evenly, stirred and heated at 80°C for 30 minutes to obtain solution A31;

[0060] S33: In a sterile environment at 80°C, add hydroxyethyl cellulose to water, stir at a stirring speed of 250 rpm for 25 minutes, and then stir at a stirring speed of 4000 rpm for 5 minutes to obtain solution B31

[0061] S34: Mix A31 and B31 and stir at a stirring speed of 200 rpm for 15 minutes, then stir at a stirring speed of 4000 rpm for 5 minutes, and cool down to 40° C. to obtain emulsion C31;

[0062] S35: Add chlorhexidine and its digluconate, cetylpyridinium chloride, and phenoxyethanol to the emulsion C21, and stir for 15 minutes at a stirring speed of 300 rpm to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com