Double-layer composite hydrogel for repairing bone and cartilage tissues as well as preparation method and application of double-layer composite hydrogel

A composite hydrogel, double-layer composite technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of poor fracture toughness, failure to achieve osteochondral joint repair, and the inability to simulate double-layer materials. The effect of reducing work intensity, simple preparation method, and good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method of the above-mentioned SA / Aker / GDL and SA / AG double-layer composite hydrogel, including the following steps:

[0049] Step 1. Heat the liquid agarose solution and mix it with the sodium alginate solution in a certain ratio for later use;

[0050] Step 2. Prepare a mixed solution of sodium alginate, magnesia feldspar, and glucono lactone in a certain proportion for use;

[0051] Step 3. Add the agarose solution / sodium alginate mixed solution of step 1 into the mold and let stand to condense into a SA / AG composite hydrogel, and add the sodium alginate / magnesia feldspar / gluconolide mixed solution of step 2 into the mold Above the formed SA / AG composite hydrogel, continue to stand and condense to obtain a double-layer composite hydrogel.

[0052] Further, in the preparation method of the double-layer composite hydrogel, the mass volume percentage (g / ml) of agarose and sodium alginate in step 1 are both 2% solutions;

[0053] F...

Embodiment 1

[0069] Example 1. Preparation of SA / Aker / GDL and SA / AG double-layer composite hydrogel

[0070] Step 1. Dissolve 2 g of sodium alginate powder in 100 mL of deionized water with continuous stirring to prepare a 2% medium viscosity sodium alginate solution. The agarose solution heated into a liquid state is prepared into a solution with a mass volume (g / ml) percentage of 2%, and mixed with the sodium alginate solution at a volume ratio of 1:1 to obtain a sodium alginate and agarose mixed solution for use;

[0071] Step 2. Grind and mix 2% SA solution and 2% Aker powder with a mass volume (g / ml) percentage of 2%, and then add GDL powder with a mass volume (g / ml) percentage of 2%, and mix evenly to prepare seaweed The mixed solution of sodium, magnesia feldspar, and gluconolide with a mass volume (g / ml) percentage of 2% for use;

[0072] Step 3. Take about 500 μL of the mixed solution of sodium alginate and agarose from step 1 into the mold and let stand to condense into a SA / AG composi...

Embodiment 2

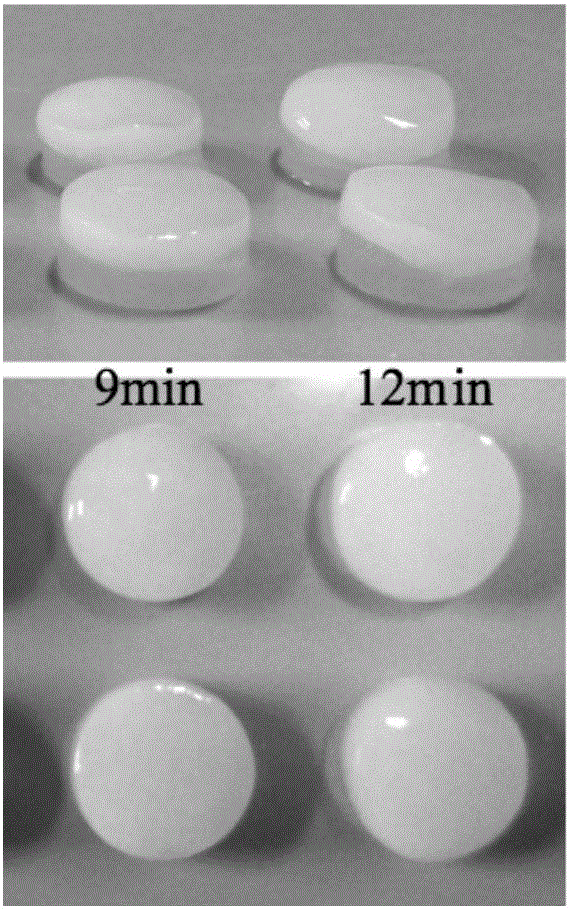

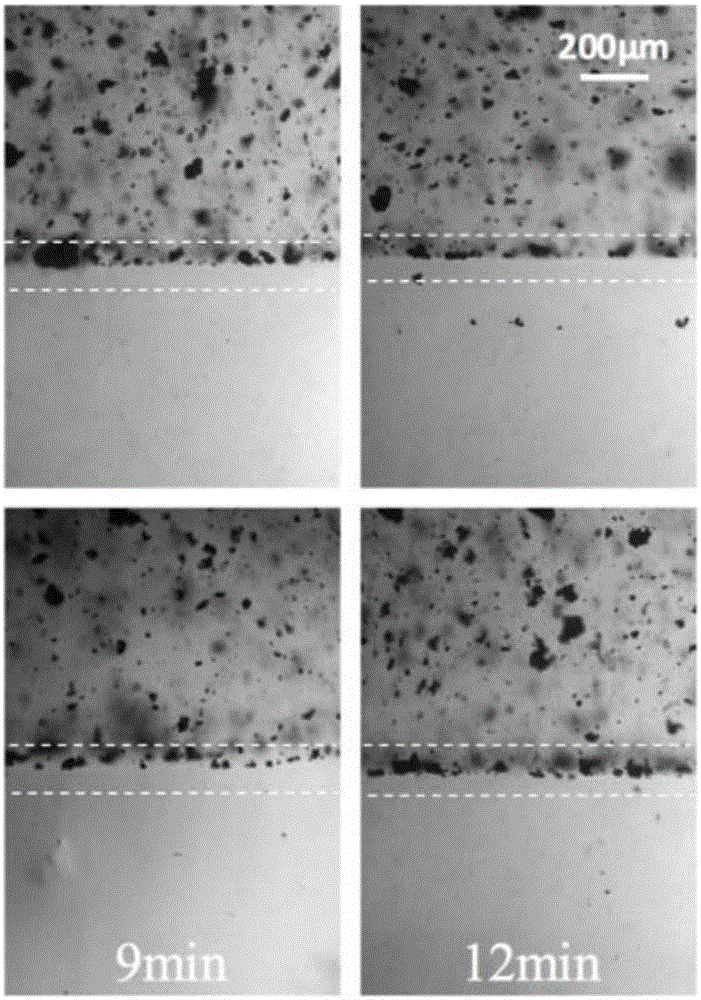

[0074] Example 2. Analysis of appearance and microstructure of SA / Aker / GDL and SA / AG double-layer composite hydrogels

[0075] The SA / Aker / GDL and SA / AG double-layer hydrogels prepared in Example 1 were freeze-dried, and the hydrogel and its connection interface were observed with an optical microscope.

[0076] Such as figure 2 As shown, the SA / AG layer and SA / Aker / GDL layer of the double-layer composite hydrogel have a tightly bonded connection interface, and the connection transition between the double-layer composite hydrogel is natural.

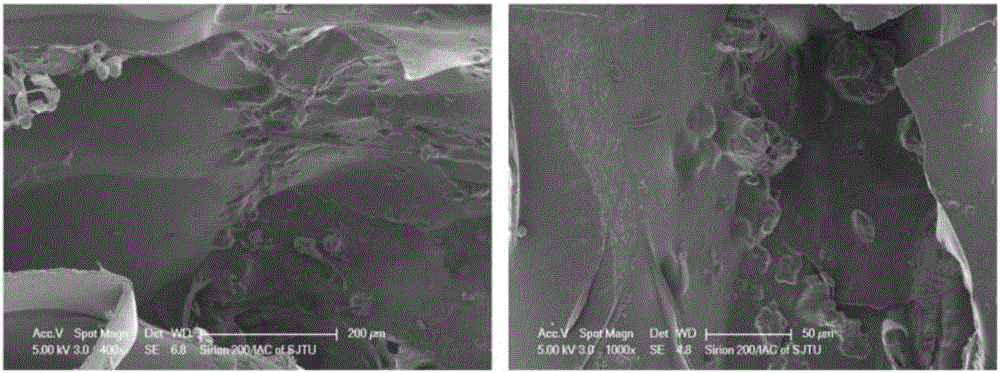

[0077] The SA / Aker / GDL and SA / AG double-layer hydrogels prepared in Example 1 were freeze-dried, and the dried double-layer composite hydrogel samples were cut to obtain a relatively flat internal cross-section. Scanning electron microscope (SEM) observed the cross-sectional structure of the junction of the double-layer hydrogel under an acceleration voltage of 10kV.

[0078] As attached image 3 As shown, the left side is the SA / AG layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com