Preparation method of constructed wetland phosphate removing substrate material

A matrix material and constructed wetland technology, applied in chemical instruments and methods, other chemical processes, biological water/sewage treatment, etc., can solve problems such as the lack of phosphorus removal matrix in constructed wetlands, achieve long-term treatment, reduce operating costs, and be economical The effect of the unity of benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

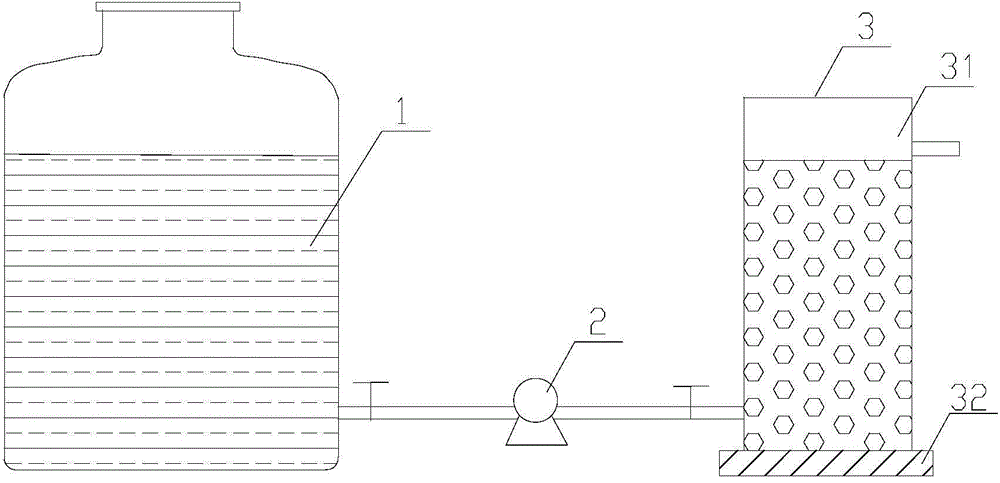

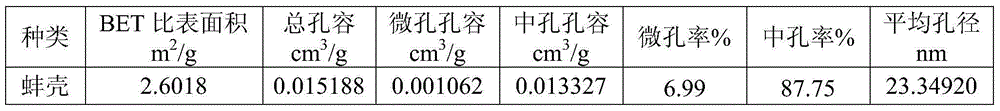

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for a constructed wetland dephosphorization matrix material, comprising the following steps,

[0021] A. Clean the mussel shells, remove the sludge on the surface of the shells and the mussel residues in the shells, and dry them naturally;

[0022] B. the natural air-dried mussel shells are crushed into fragments with a diameter of 30mm;

[0023] C. further pulverize the fragments to obtain the pulverized clam shell fragments;

[0024] D. screening the crushed clam shell fragments to prepare a phosphorus removal matrix material for constructed wetlands.

Embodiment 2

[0026] A preparation method for a constructed wetland dephosphorization matrix material, comprising the following steps,

[0027] A. Wash the clam shells with tap water, remove the sludge on the surface of the clam shells and the clam residues in the clam shells, and dry them naturally;

[0028] B. the natural air-dried mussel shells are crushed into pieces with a diameter of 50mm with a coarse crusher;

[0029] C. be that the high-speed pulverizer of 10000rpm is further pulverized fragment with rotating speed, obtains the mussel shell fragment after pulverizing, pulverizing time is 1 minute;

[0030] D. Screen the crushed clam shell fragments with a 100-mesh sieve to obtain clam shell particles with a particle size of 0.15-0.3 mm.

[0031] The prepared wetland phosphorus removal matrix material volume density is controlled to 1800kg / m 3 .

Embodiment 3

[0033] A preparation method for a constructed wetland dephosphorization matrix material, comprising the following steps,

[0034] A. Clean the mussel shells, remove the sludge on the surface of the shells and the mussel residues in the shells, and dry them naturally;

[0035] B. the clamshell that the natural air-drying is crushed into the fragment that diameter is 35mm;

[0036] C. further pulverize the fragments to obtain the pulverized clam shell fragments;

[0037] D. Screen the crushed mussel shell fragments with a 80-mesh sieve to obtain clam shell particles with a particle size of 0.3-0.45 mm.

[0038] The volume density of the prepared phosphorus removal matrix material for constructed wetlands is controlled to 1700kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com