Preparation method of cadmium sulfide carbon-based composite material serving as photoelectric catalyst

A technology of carbon-based composite materials and catalysts, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor light stability of cadmium sulfide, low sunlight absorption efficiency, photogenerated electrons and holes Fast recombination and other issues, to achieve good photostability, high visible light response, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

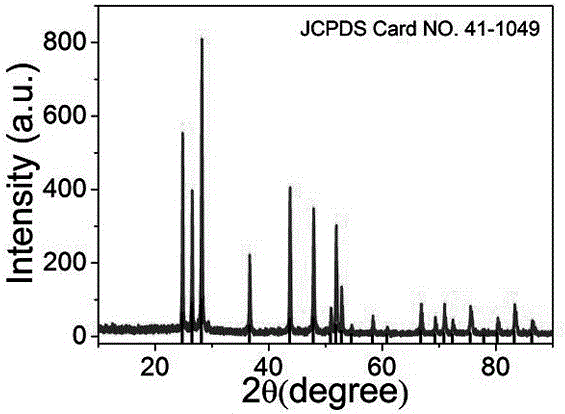

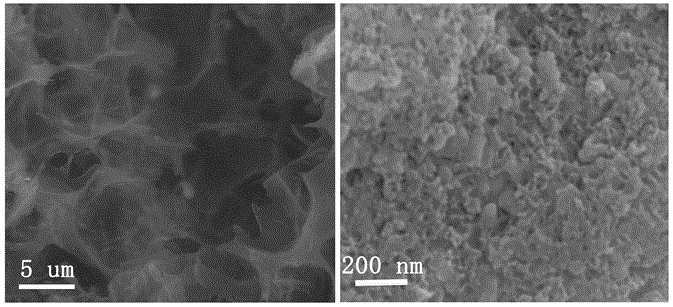

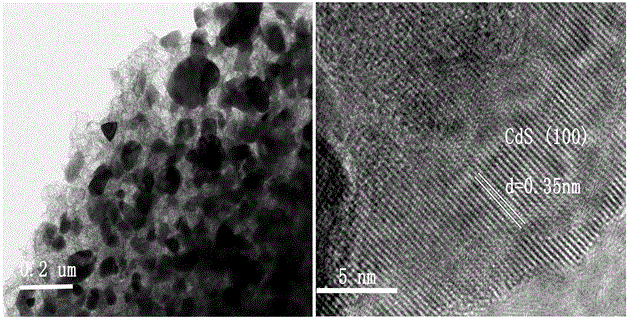

[0023] Embodiment one, according to figure 1 , 2 , Shown in 3, 4, a kind of cadmium sulfide carbon-based composite material is used as the preparation method of photoelectric catalyst, and concrete steps are as follows:

[0024] Step 1, using the principle of carrageenan gel to drop 2g of ι-carrageenan raw material with a mass fraction of 2% into 100ml of ethanol solution of hydrochloric acid with a concentration of 2mol L-1 to form a gel and remove impurities from the gel deal with;

[0025] Step 2, immerse the carrageenan gel after removing impurities into the ethanol solution of 1.5mol L-1 cadmium acetate in the amount concentration of 100ml of substance, and process 3 to 5 times;

[0026] Step 3, wash the above-mentioned gel with ethanol and water for 2 to 3 times, put the treated gel in the refrigerator, and then freeze-dry to form cadmium-carrageenan airgel;

[0027] Step 4: The cadmium-carrageenan airgel is calcined in a tube furnace through a certain carbonization p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com