Nanometer alumina condensate paste and preparation method thereof

A technology of nano-alumina and concentrated slurry, which is applied in the field of nano-materials, can solve problems such as dispersed nano-alumina, and achieve the effects of storage stability, simple preparation process, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

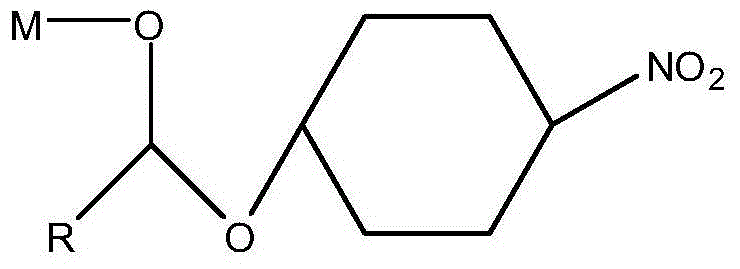

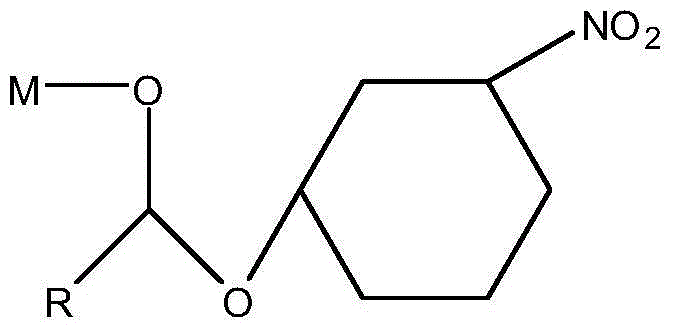

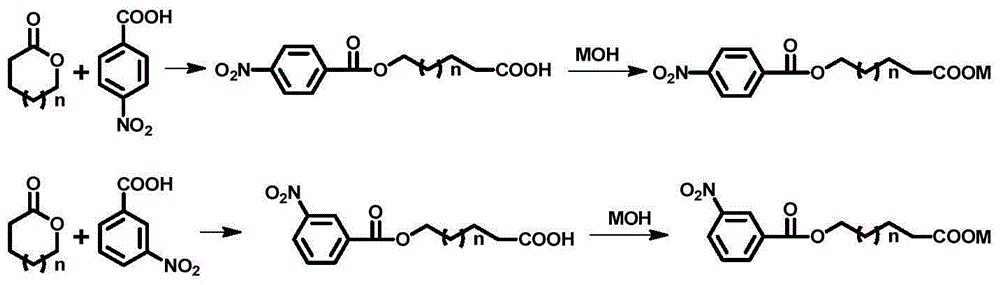

Method used

Image

Examples

Embodiment 1

[0036] In parts by weight, the nano-alumina concentrated slurry is composed of 100 parts of nano-alumina with an average primary particle diameter of less than 50nm, 8 parts of organic corrosion inhibitor, 0.2 part of antirust pigment, 0.5 part of additive, and 18 parts of organic solvent. composition. Among them, the organic corrosion inhibitor is sodium p-nitrolaurate, the anti-rust pigment is strontium-containing phosphate SRPP, and the additives are: BYK-P104S wetting and dispersing agent (German BYK company BYK) 0.2 parts, BYK-310 0.2 parts of leveling agent (BYK, Germany), 0.1 part of BENTONE 34 organic bentonite anti-settling agent (RHEOX, USA), 1 part of toluene, 5 parts of ethyl acetate, 12 parts of acetone.

[0037] The preparation method of nano-alumina concentrated slurry, the specific steps are as follows:

[0038] (1) Weigh each component in proportion;

[0039] (2) Mix organic corrosion inhibitor, antirust pigment, auxiliary agent and organic solvent evenly; ...

Embodiment 2

[0043] In terms of parts by weight, the concentrated nano-alumina slurry consists of 100 parts of nano-alumina with an average particle size of primary particles below 50nm, 5 parts of organic corrosion inhibitors, 0.3 parts of antirust pigments, 0.3 parts of additives, and 15 parts of organic solvents. composition. Among them, the organic corrosion inhibitor is sodium p-nitropalmitate, the anti-rust pigment is phosphate SAPP containing strontium, and the additives are: DISPERBYK-106 wetting and dispersing agent (German BYK company) 0.1 part, BYK- 0.1 part of VP-354 leveling agent (BYK company in Germany), 0.1 part of BENTONE 27 organic bentonite anti-settling agent (RHEOX company in the United States), 0.1 part of organic solvent: 1 part of xylene, 3 parts of butyl acetate, cyclohexanone 11 servings.

[0044] The preparation method of nano-alumina concentrated slurry, the specific steps are as follows:

[0045] (1) Weigh each component in proportion;

[0046] (2) Mix organic...

Embodiment 3

[0050] In parts by weight, the nano-alumina concentrated slurry is composed of 100 parts of nano-alumina with an average particle size of primary particles below 50nm, 10 parts of organic corrosion inhibitor, 0.1 part of antirust pigment, 0.6 part of additive, and 20 parts of organic solvent. composition. Among them, the organic corrosion inhibitor is sodium p-nitrostearate, the antirust pigment is zinc orthophosphate, and the additives are: 0.2 parts of DISPERBYK-110 wetting and dispersing agent (BYK Company of Germany), BYK-310 leveling agent 0.2 parts of BENTONE SD-2 organic bentonite anti-sedimentation agent (RHEOX company of the United States) 0.2 parts, organic solvent: 1 part of toluene, 6 parts of butyl acetate, 13 parts of cyclohexanone.

[0051] The preparation method of nano-alumina concentrated slurry, the specific steps are as follows:

[0052] (1) Weigh each component in proportion;

[0053] (2) Mix organic corrosion inhibitor, anti-rust pigment, auxiliary agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com