Sulfur and indium compound system quantum dot light conversion film and preparation method thereof

A technology of quantum dots and compounds is applied in the field of quantum dot light-converting film of sulfur indium compound system and its preparation, which can solve the problems of mismatch of lifespan of light-converting agent and matrix resin, short service life of light-converting film, affecting plant absorption, and the like. Achieve the effect of improving crop quality, improving absorption and conversion efficiency, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned sulfur indium compound system quantum dot light conversion film comprises the following steps:

[0047] 1) Granulation: Add the masterbatch matrix, sulfur indium quantum dot light converting agent, lubricant, light stabilizer and antioxidant into the high-speed mixer, mix well, and then transfer the material to the twin-screw extruder, extrude Granulating to obtain the masterbatch of light-changing agent;

[0048] 2) Film blowing: fully mix the masterbatch of the light converting agent and the film matrix, and then put the materials into a blow molding machine for blow molding to obtain a quantum dot light conversion film of sulfur indium compound system.

[0049] Preferably, the operating temperature of the twin-screw extruder described in step 1) is 180-200° C., and the screw speed is 300-500 r / min.

[0050] Preferably, the melting temperature of the material in the blow molding machine in step 2) is 170-190°C, and the te...

Embodiment 1

[0053] The raw material composition of a sulfur-indium compound system quantum dot light conversion film is shown in Table 1:

[0054] Table 1 The raw material composition table of a sulfur indium compound system quantum dot light conversion film

[0055] raw material parts by mass Masterbatch matrix (high density polyethylene) 100 Film substrate (polyethylene) 1500 Light converting agent (CuInS 2 : Zn 0.99 Ca 0.01 S) 1 N,N'-Ethylene bisstearamide 2 Light stabilizer 944 5 Light Stabilizer 770 5 Antioxidant 1010 5

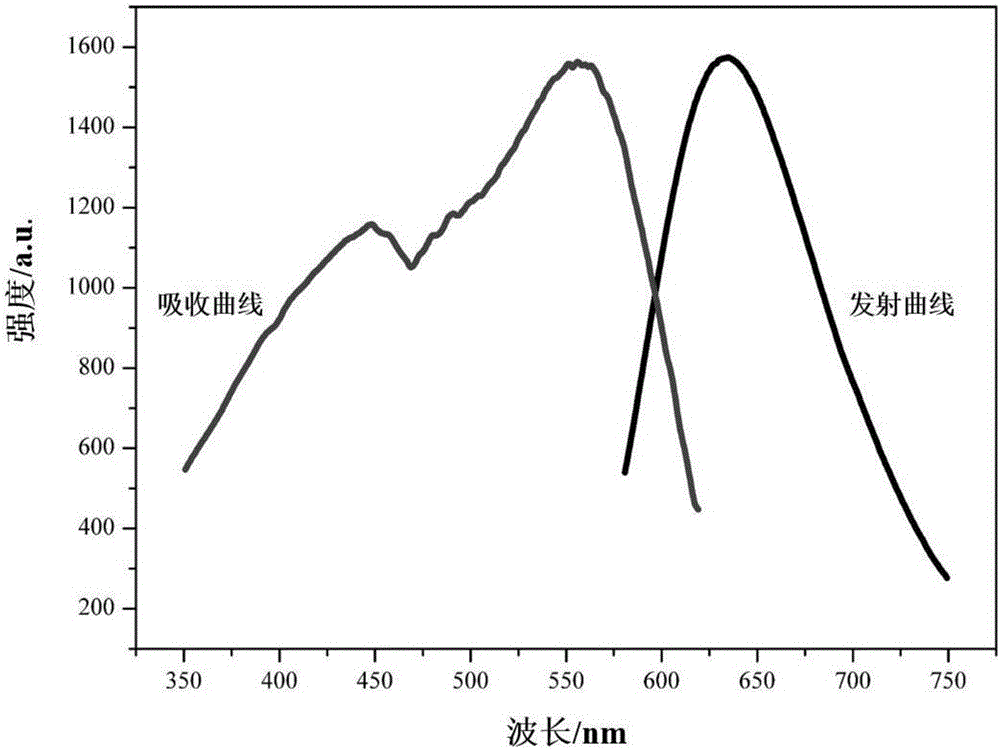

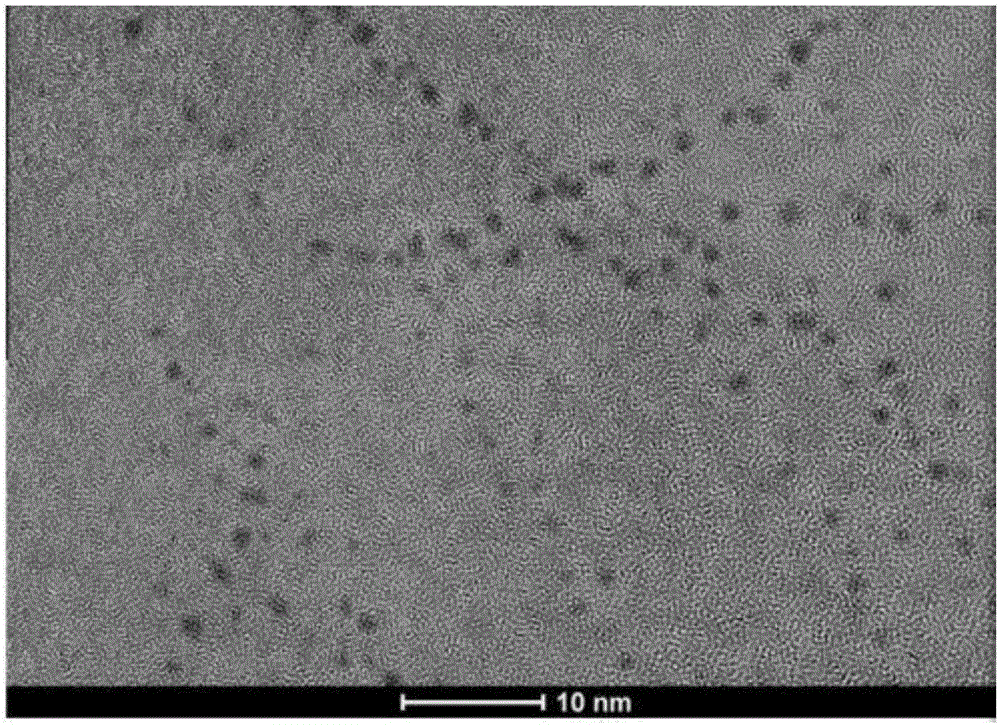

[0056] The light conversion agent CuInS selected in this embodiment 2 : Zn 0.99 Ca 0.01 The absorption spectrum and emission spectrum of S are as follows figure 1As shown, the transmission electron microscope image is shown in figure 2 shown.

Embodiment 2

[0058] The raw material composition of a sulfur-indium compound system quantum dot light conversion film is shown in Table 2:

[0059] Table 2 The raw material composition table of a sulfur indium compound system quantum dot light conversion film

[0060] raw material parts by mass Masterbatch matrix (polyethylene) 100 Film substrate (polyvinyl chloride) 1000 Light converting agent (CuInS 2 : Zn 0.90 Sr 0.10 S) 0.01 N,N'-Ethylene bisstearamide 1.5 Light stabilizer 622 5 Antioxidant 1010 2.5 Antioxidant 264 0.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com