Fixed bed reactor and method for preparing activated carbon by continuously pyrolyzing biomass at low temperature

A technology for preparing activated carbon and reactors, which is applied in the direction of biofuels, educts, indirect heating and carbonization, etc. It can solve the problem of not realizing high-temperature pyrolysis of non-condensable gas to provide heat, reducing the processing capacity and efficiency of the device, and unable to realize continuous feeding and discharging, etc. problems, to achieve direct recycling, improve processing capacity and efficiency, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

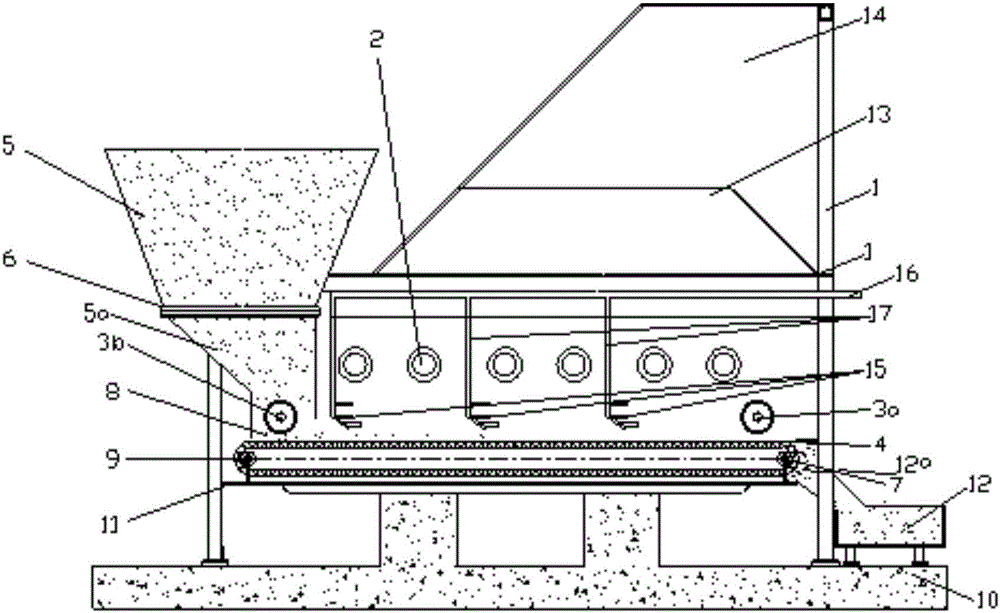

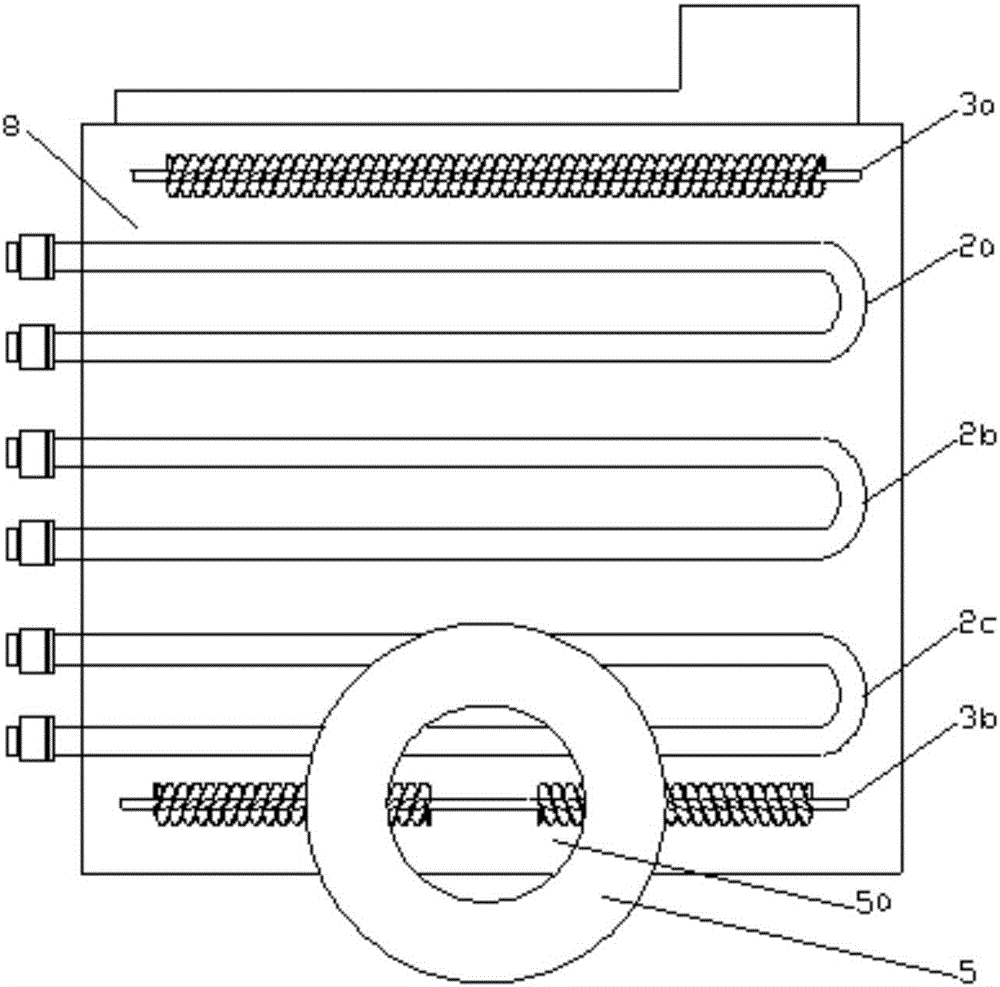

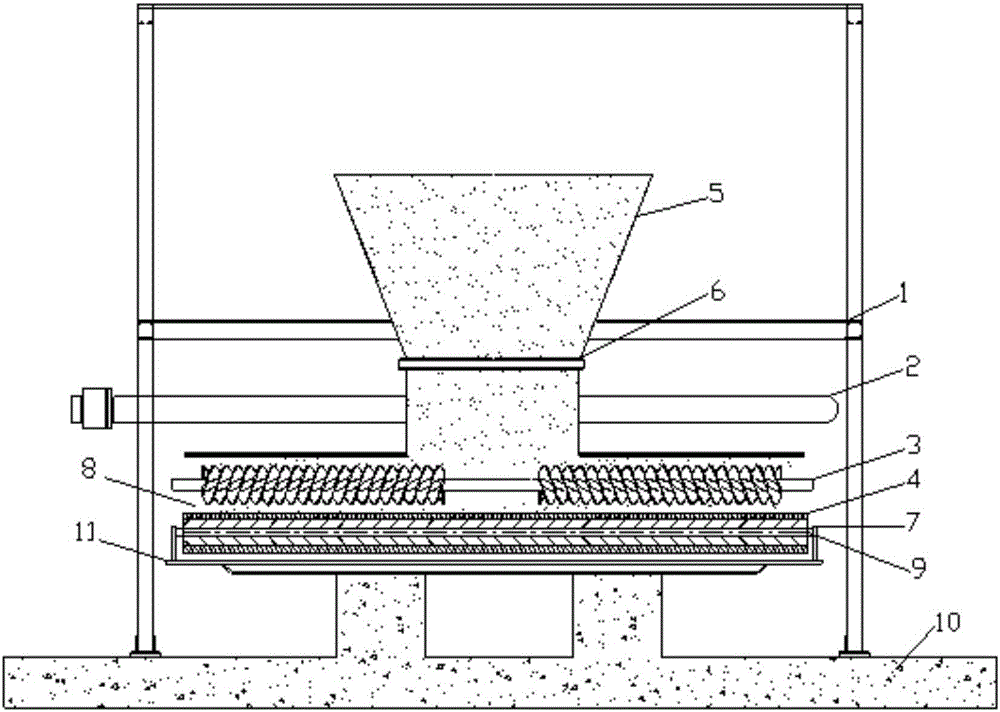

[0105] Manzhouli provides biomass with a particle size of 0.3-0.6 mm as raw material (see Table 1 for biomass analysis data). The material is first stored in the feed bin 5, and the gate valve 6 is opened. Under the action of gravity, the material is discharged from the feed bin 5 The blanking chute at place slides in the reaction chamber 8.

[0106] Under the rotation of the feeding screw 3b and the driving of the transmission bearing 9, the biomass raw material is evenly distributed on the material plate 4 and moves horizontally to the discharge end at the same time. Control the speed of the feeding screw 3b and the transmission bearing 9, so that the material thickness on the entire material plate 4 is 100mm, and then close the gate valve 6. Turn on the radiant tube combustion system. When the material temperature is lower than 280°C, control the heating rate of radiant tube 2 to 45°C / min; when the material temperature is higher than 280°C, control the heating rate of radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com