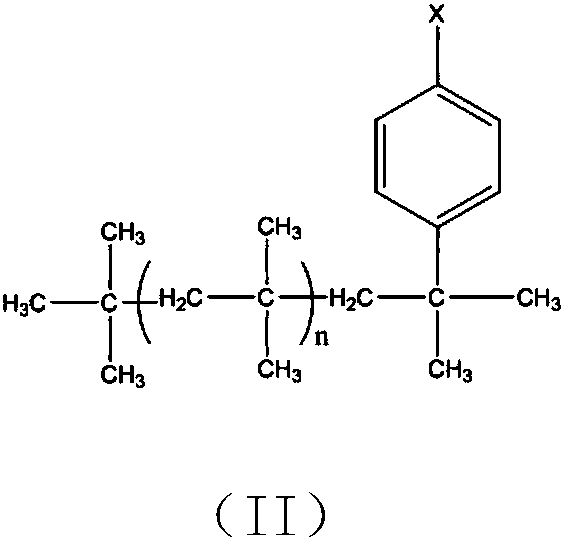

A kind of novel polyisobutylene amine used as gasoline detergent and its synthetic method

A technology for polyisobutylene amine and gasoline detergent, which is applied in the petrochemical field, can solve the problems of high viscosity of the reaction system, difficult to achieve catalyst regeneration, secondary environmental pollution, etc., achieves low production cost, avoids the use of precious metal catalysts, reduces The effect of gasoline consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

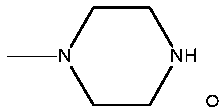

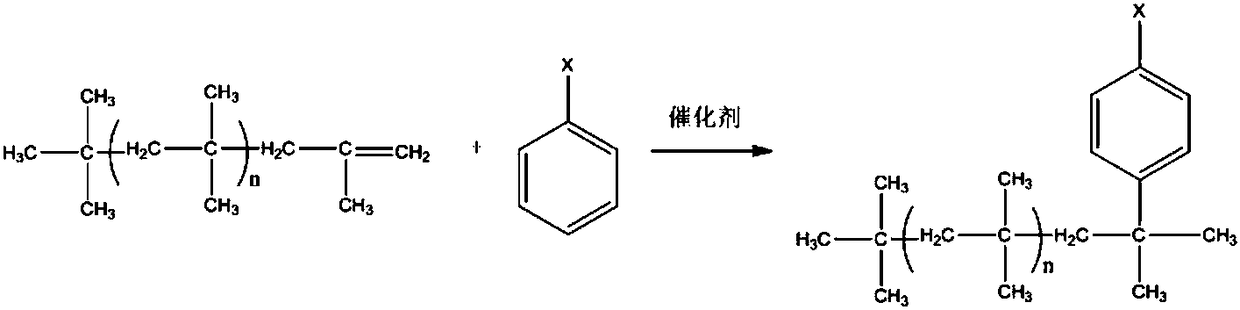

Method used

Image

Examples

example 1

[0047] Add 93 grams of aniline, 1000 grams of highly active polyisobutylene (molecular weight 1000), 30 grams of boron trifluoride ether and 300 ml of mixed trimethylbenzene into the enamel reaction kettle, replace the air in the reaction kettle with nitrogen, heat up to 150 ° C and stir 8 hours. After the reaction was completed, cool to room temperature, add 8 grams of butanol, neutralize with excess NaOH and wash with water to pH=8~10, anhydrous NaOH 2 SO 4 After drying and filtering, the filtrate was distilled under reduced pressure to remove the solvent and other low boilers to obtain 1028 g of the product.

example 2

[0049] 137 grams of N-phenylethanolamine, 1000 grams of highly active polyisobutylene (molecular weight 1000), 40 grams of boron trifluoride ether and 450 milliliters of heavy aromatics are added in the enamel reaction kettle, and the air in the reaction kettle is replaced with nitrogen, and the temperature is raised to Stir at 170°C for 10 hours. After the reaction is completed, cool to room temperature, add 15 grams of polyoxyethylene polyoxypropylene polyether, neutralize with excess NaOH and wash with water to pH = 8 ~ 10, anhydrous Na 2 SO 4 After drying and filtering, the filtrate was distilled under reduced pressure to remove the solvent and other low boilers to obtain 1095 g of the product.

example 3

[0051]Add 137 grams of N-phenylethylenediamine, 1000 grams of highly active polyisobutylene (molecular weight 1000), 30 grams of boron trifluoride ether and 350 milliliters of mixed trimethylbenzene into the enamel reaction kettle, and replace the air in the reaction kettle with nitrogen , heated to 160°C and stirred for 8 hours. After the reaction was completed, cool to room temperature, add 10 g of butanol, neutralize with excess KOH and wash with water to pH = 8-10, anhydrous Na 2 SO 4 After drying and filtering, the filtrate was distilled under reduced pressure to remove the solvent and other low boilers to obtain 1082 g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com