Method for preparing nano bionic structure on titanium alloy surface by micro-arc discharge

A micro-arc discharge and nano-bionic technology, which is applied in the direction of electrolytic inorganic material coating, etc., to achieve the effects of firm bonding, cost reduction, and strong biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

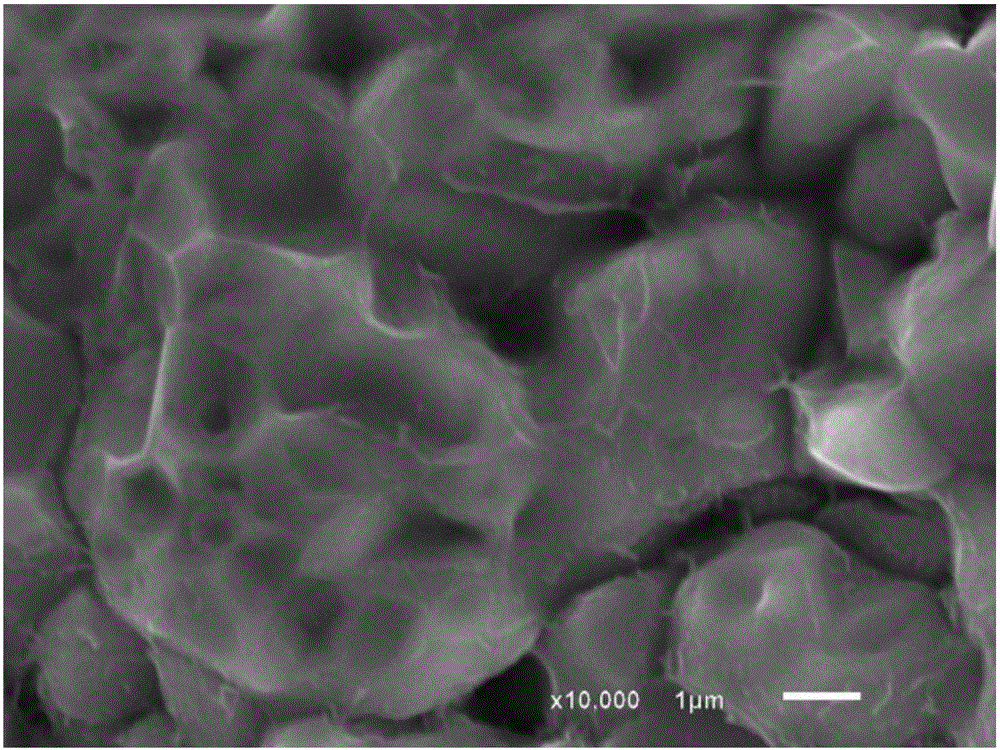

Image

Examples

Embodiment 1

[0025] First, take 2 / 3 volume of distilled water in a 1L tank, dissolve 3500g urea and 4000g potassium nitrate in turn, and after all the reagents in the tank are dissolved, pour 1500g sodium chloride into the tank solution under rapid stirring until it is completely mixed. , and finally add water to 1L to obtain an electrolyte; put the pure titanium parts into the prepared electrolyte, use the pure titanium parts as the cathode and graphite as the anode, and put the titanium alloy parts into the electrolyte after the voltage rises to 300V for 10 minutes , the nano-bionic structure can be prepared on the surface of titanium alloy by micro-arc discharge.

Embodiment 2

[0027] First, take 2 / 3 volume of deionized water in a 1L tank, dissolve 3000g of formamide and 5000g of sodium nitrate in sequence, and after all the reagents in the tank are dissolved, pour 1000g of potassium chloride into the tank under rapid stirring. Until it is completely mixed evenly, finally add water to 1L to obtain an electrolyte; put the Ti-6Al-4V piece into the prepared rapid micro-arc nitriding solution, use the Ti-6Al-4V piece as the cathode, graphite as the anode, and the voltage rises to After 450V, put the titanium alloy parts into the electrolyte and treat them for 6 minutes to prepare nano-bionic structures on the surface of the titanium alloy by micro-arc discharge.

Embodiment 3

[0029] First, take 2 / 3 volume of distilled water in a 1.5L tank, dissolve 3500g of urea and 4000g of sodium nitrate in turn, after all the reagents in the tank are dissolved, pour 1000g of sodium chloride into the tank under rapid stirring until completely mixed Evenly, finally add water to 1.5L to obtain electrolyte; put the Ti-15Mo parts into the prepared rapid micro-arc nitriding solution, use the Ti-15Mo parts as the cathode and graphite as the anode, and after the voltage rises to 600V, the titanium alloy parts Putting it in the electrolyte and treating it for 5 minutes, the nano-bionic structure can be prepared on the surface of the titanium alloy by micro-arc discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com