Modified gardenia yellow and method for dyeing cationic modified cellulose fabric by using modified gardenia yellow

A technology of cellulose fiber and gardenia yellow, applied in the field of textile dyeing and finishing, can solve the problems of low light fastness and perspiration fastness, increased energy level, oxidation reaction, etc., and achieve the reduction of non-renewable mineral resources And the use of chemical raw materials, good biodegradable performance, the effect of improving reaction rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This example provides a modified natural dye gardenia yellow and a method for dyeing cationic modified cotton fabric using it.

[0036] The preparation method of modified natural dye gardenia yellow comprises the following steps:

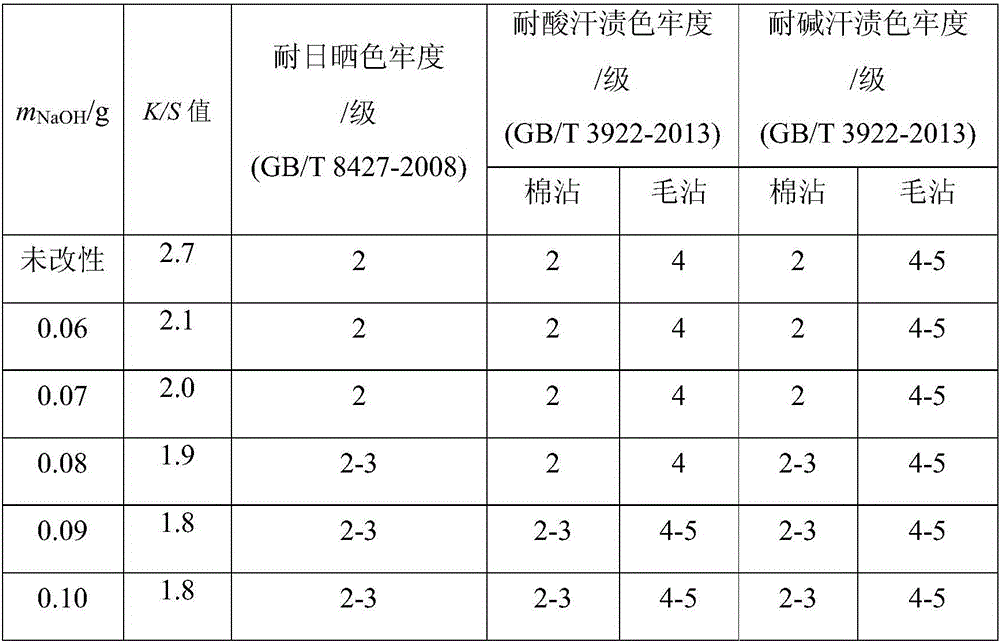

[0037] Add 0.5g gardenia yellow in the three-necked flask, a certain amount of NaOH (the amount is set to 0.06g, 0.07g, 0.08g, 0.09g, 0.10g respectively) and 80mL n-butanol to condense and reflux, and the three-necked flask is refluxed during the condensation and reflux process. The flask is heated from normal temperature to 70°C (during the heating process, a magnetic stirrer is used to magnetically stir the reactants in the flask, and the stirring time can be 10 minutes), and the temperature is kept and stirred for 3.0 hours to obtain the product liquid;

[0038] After cooling the product solution to room temperature, the n-butanol was removed by rotary evaporation, and then dried at 100°C to obtain the modified natural dye gardenia yellow....

Embodiment 2

[0052] This example provides a modified natural dye gardenia yellow and a method for dyeing cationic modified cotton fabric using it.

[0053] The preparation method of modified natural dye gardenia yellow comprises the following steps:

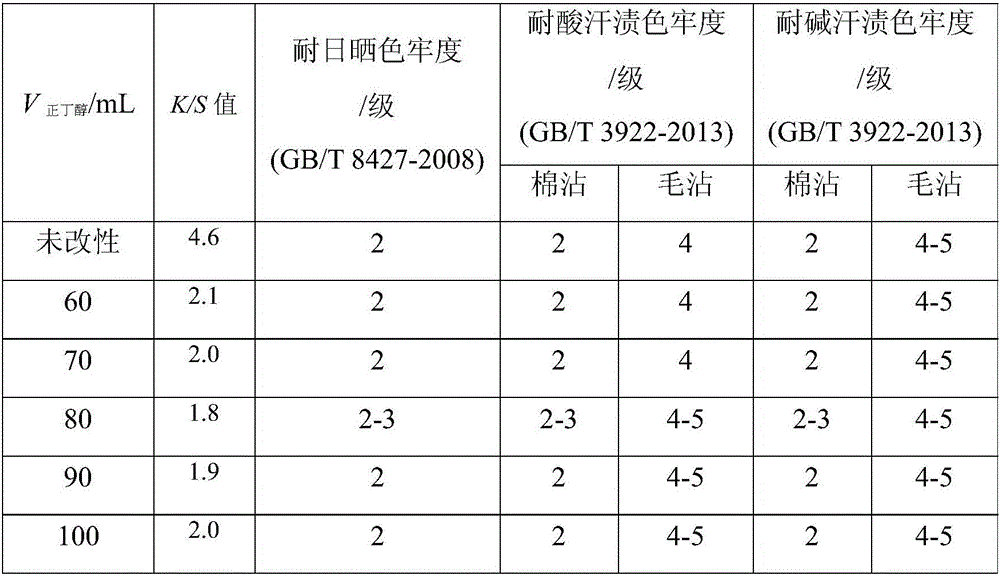

[0054] Add 0.5g gardenia yellow, 0.09g NaOH and a certain amount of n-butanol (the amount is set to 60mL, 70mL, 80mL, 90mL, 100mL respectively) into the three-necked flask, condense and reflux, and raise the temperature to 70°C at room temperature (during the heating process, the magnetic After stirring for 10 min), heat-insulated and stirred for 3.0 h to obtain the product solution;

[0055] After cooling the product solution to room temperature, the n-butanol was removed by rotary evaporation, and then dried at 100°C to obtain the modified natural dye gardenia yellow.

[0056] Utilize above-mentioned modified natural dye gardenia yellow to carry out dyeing through the cotton fabric of cationic modification, dyeing process is as follows:

...

Embodiment 3

[0065] This example provides a modified natural dye gardenia yellow and a method for dyeing cationic modified cotton fabric using it.

[0066] The preparation method of modified natural dye gardenia yellow comprises the following steps:

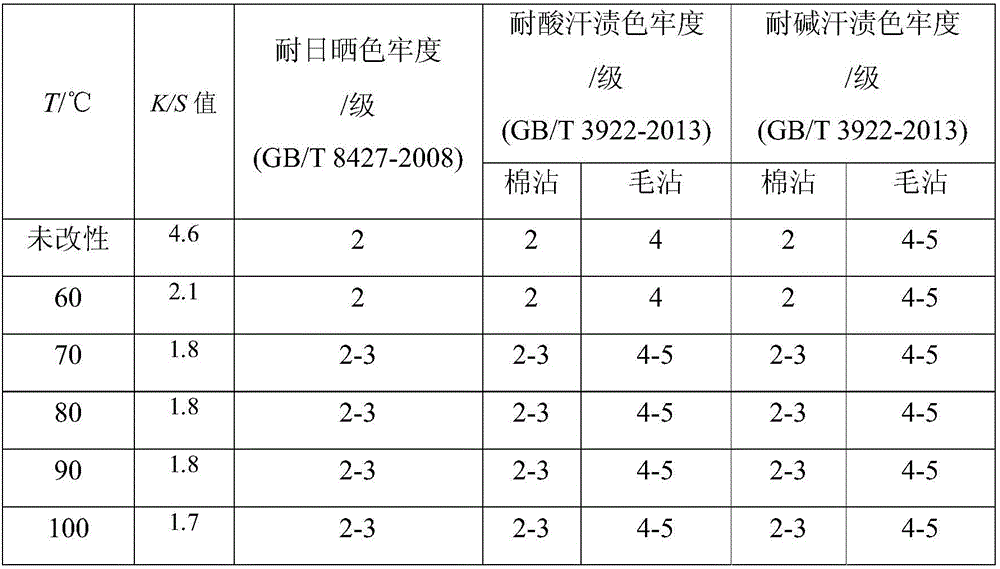

[0067] Add 0.5g gardenia yellow, 0.09g NaOH and 80mL n-butanol into the three-necked flask, condense and reflux, stir magnetically at room temperature for 10min, then raise the temperature to a certain temperature (the temperature is set to 60°C, 70°C, 80°C, 90°C, 100°C), heat-preserved and stirred for 3.0 hours to obtain the product solution;

[0068] After cooling the product solution to room temperature, the solvent was removed by rotary evaporation, and then dried at 100°C to obtain the modified natural dye gardenia yellow.

[0069] Utilize above-mentioned modified natural dye gardenia yellow to carry out dyeing through the cotton fabric of cationic modification, dyeing process is as follows:

[0070] Preparation of dyeing solution: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com