Composite coating heat-insulating corrosion-resistant oil pipe

A composite coating and oil pipe technology, applied in coatings, anti-corrosion coatings, drilling pipes, etc., can solve the problems of downhole accidents, maintenance of human resources, and high costs, and achieve the effect of inhibiting the precipitation of wax crystals and having obvious thermal insulation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

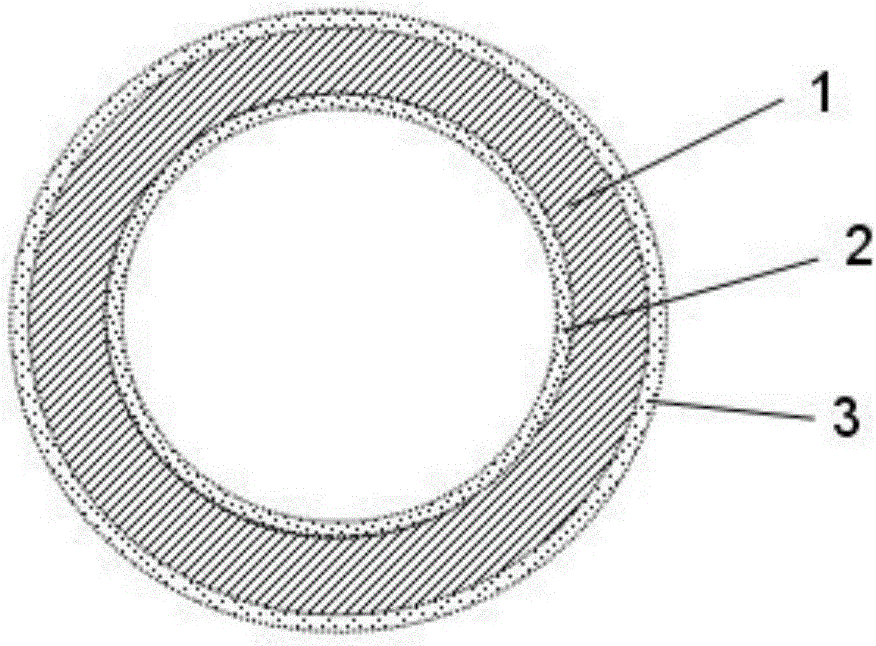

[0024] Such as figure 1 As shown, a composite coating heat-insulating and anti-corrosion oil pipe, the substrate of the heat-insulating oil pipe is a metal oil pipe 1, the inner surface of the metal oil pipe 1 is coated with an airgel inner coating 2, and the outer surface is coated with an anti-corrosion air gel Glue outer coating3. The airgel inner coating 2 and the anti-corrosion airgel outer coating 3 constitute the airgel composite coating.

[0025] When coating the inner surface of the metal oil pipe 1 with an airgel inner coating 2 and the outer surface of the metal oil pipe 1 with an anti-corrosion airgel outer coating 3, the inner and outer surfaces of the oil pipe must first be polished to remove rust and dirt After phosphating, coating is carried out.

[0026] Run the above-mentioned airgel composite coating heat-insulated tubing into the required depth according to the wax deposition position of a single well. For example, if the pump depth of a well is 2000m, an...

Embodiment 2

[0028] On the basis of Example 1, an airgel inner coating 2 and an anti-corrosion airgel outer coating 3 are evenly coated on the inner and outer walls of the metal oil pipe 1: the inner airgel coating 2 is formed from the inner The outer layer is composed of a high-solid epoxy bottom layer and an airgel slurry surface layer. The high-solid epoxy bottom layer and the airgel slurry surface layer are sprayed once to form a film. The airgel inner coating 2 is preferably 400-600 μm in thickness; The anti-corrosion airgel outer coating 3 is composed of a high-solid epoxy bottom layer and an anti-corrosion airgel surface layer from the inside to the outside. The high-solid epoxy bottom layer and the anti-corrosion airgel surface layer are sprayed once to form a film. The coating thickness of the gel outer coating 3 is preferably about 1 mm; the inner and outer composite coatings can effectively insulate the oil pipe, reduce the surface roughness of the oil pipe, prevent the condensat...

Embodiment 3

[0030] On the basis of the above examples, the high-solid epoxy bottom layer is cured with high-solid epoxy resin, and the solid content of the high-solid epoxy resin is greater than 94% of the coating thickness of the high-solid epoxy bottom layer It is preferably 150-300 μm, and the high-solid epoxy resin is purchased from Shanghai Xitai Industrial Coatings Co., Ltd.

[0031] The airgel paste surface layer is formed by mixing hydrophobic airgel powder, glass fibers and film-forming aids according to the mass ratio of 6:3:1; the heat conduction of the airgel paste surface layer The coefficient is less than 0.08W / m.k, and the coating thickness is not less than 300μm.

[0032] The anti-corrosion airgel surface layer is formed by mixing polyethylene, hydrophobic airgel powder, glass fiber and film-forming aids in a mass ratio of 3:4:2:1, and the anti-corrosion airgel The thermal conductivity of the rubber surface layer is less than 0.20W / m.k, and the coating thickness is prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com