A bisphenol A electropolymerization film functionalized carbon nanotube/cadmium sulfide composite electrode and its preparation method and application

A carbon nanotube and composite electrode technology is applied in the fields of electrochemical variables of materials, material analysis by electromagnetic means, measurement devices, etc., which can solve the problems that there are no reports of bisphenol A electropolymerized film-functionalized carbon nanotube electrodes, etc. Achieve good redox activity, low cost, and the effect of increasing the amount of electropolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of bisphenol A electropolymerization film functionalized carbon nanotube / cadmium sulfide composite electrode

[0035] The SWCNTSs / CdS / ITO electrode in this example is prepared by the following method:

[0036] (1) Preparation of CdS / ITO electrode: Using cyclic voltammetry (CV) electrodeposition technology, in the three-electrode system, the working electrode is indium tin oxide ITO conductive glass, the counter electrode is titanium sheet, and the reference electrode is saturated sweetener. Mercury electrode, the electrolyte is sodium thiosulfate solution containing 0.01mol / L cadmium chloride, 0.01mol / L pH 2.0, the potential range of deposition is -0.3V~-0.9V, and the sweep rate is 0.05V s -1 , the number of scanning circles is 100 circles; in order to remove the undeposited electrode, the modified electrode was immersed in double distilled water for 5 minutes, then taken out and dried in an oven at 40°C for 12 hours, and the CdS / ITO electrode was ...

Embodiment 2

[0041] Example 2 Visible light enhanced electropolymerization of bisphenol A on SWCNTs / CdS / ITO electrode

[0042] The SWCNTs / CdS / ITO electrode prepared in Example 1 promotes the electropolymerization of bisphenol A under visible light radiation, and the specific operation steps are as follows:

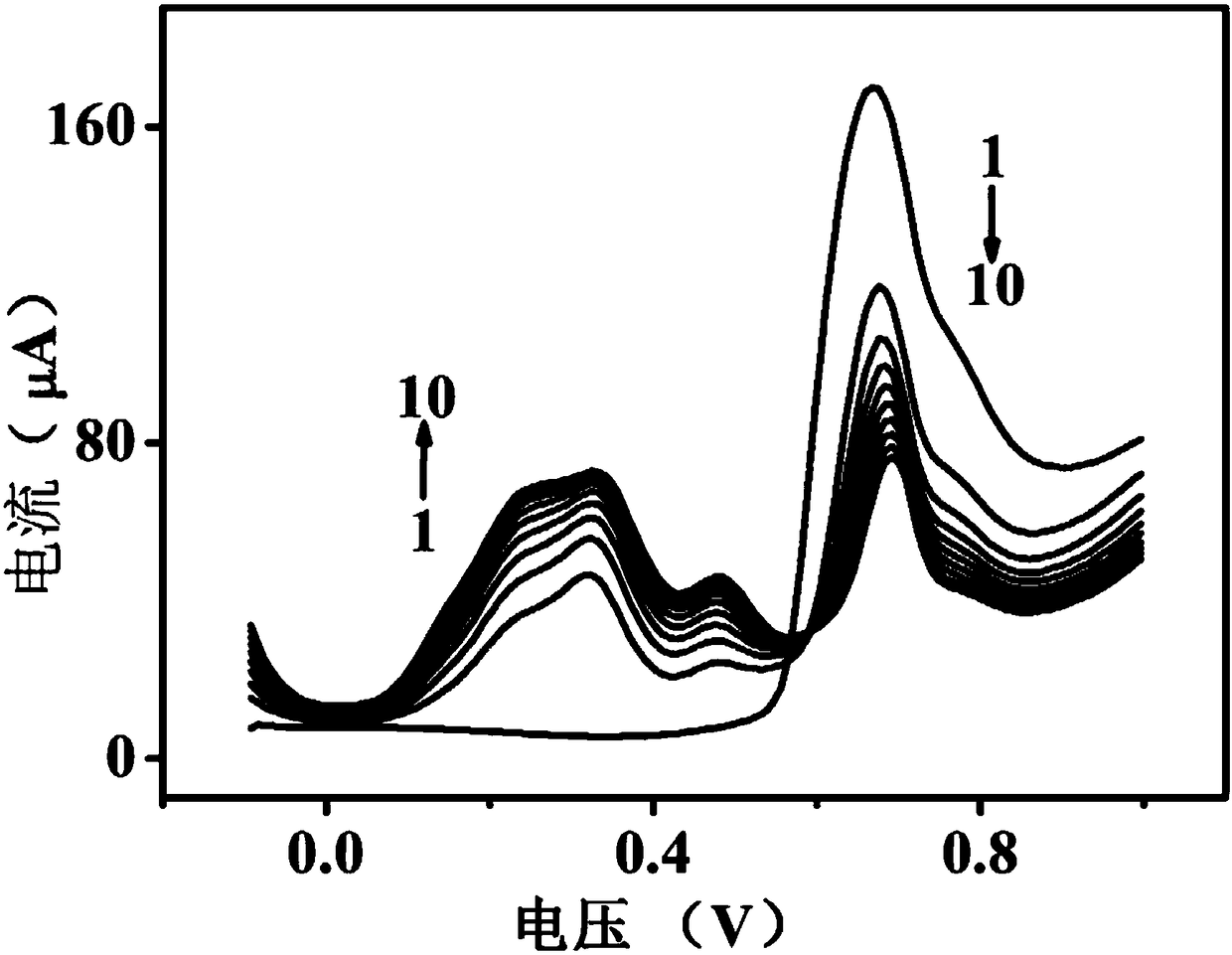

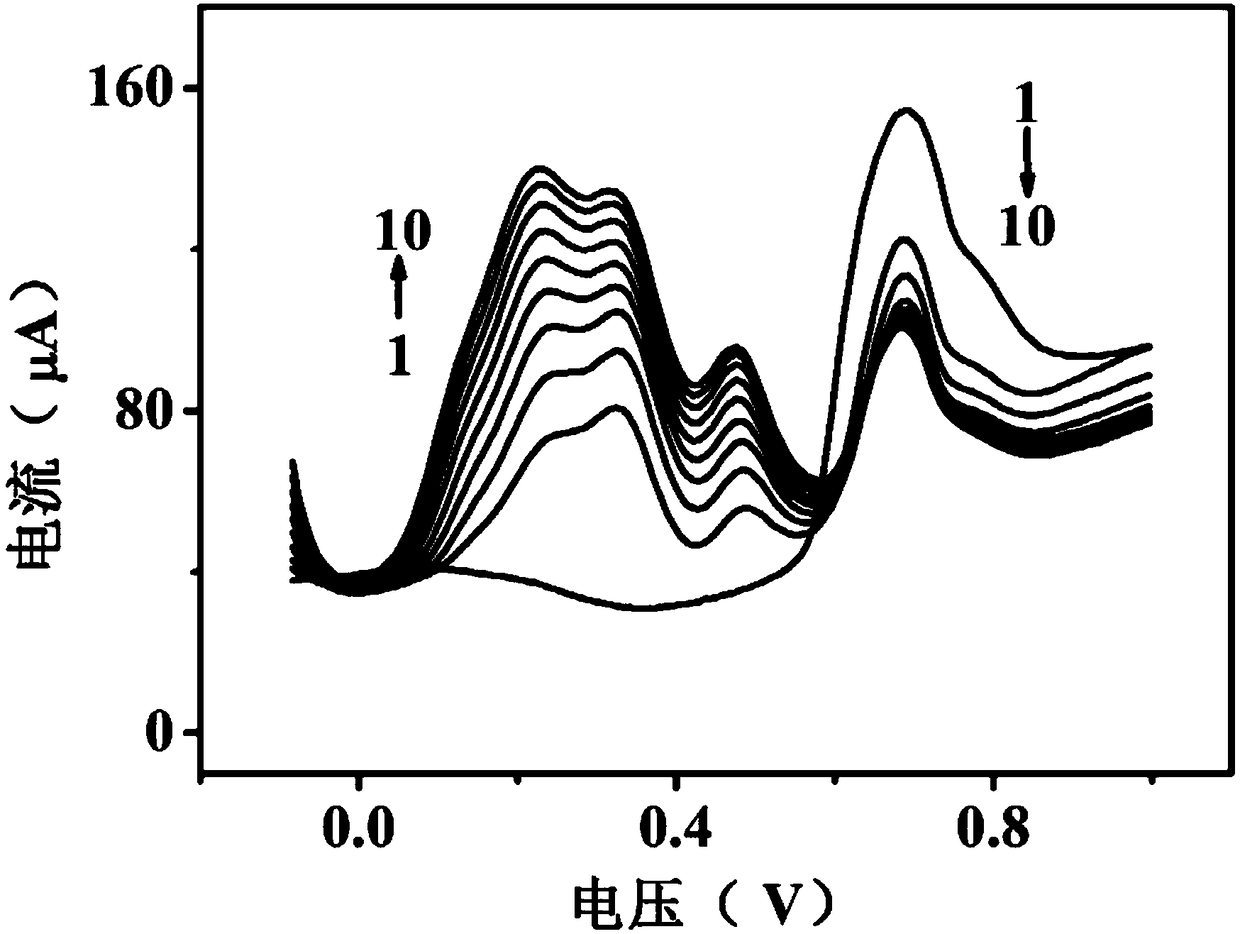

[0043] at 0.18mW cm -2 Under visible light radiation, differential pulse voltammetry electropolymerization technology is adopted. In the three-electrode system, the working electrode is SWCNTs / CdS / ITO electrode, the counter electrode is titanium sheet, the reference electrode is saturated calomel electrode, and the electrolyte is pH= 3.0 0.2mmol / L bisphenol A, 0.1mol / L sodium chloride solution, the potential range of deposition is -0.1V~1.0V, and the number of scanning circles is 10 circles, the results are as follows figure 2 As shown, the peak potential of the tenth differential pulse scan under visible light conditions is 0.322V, and the peak current is 96.8μA. and figure 1 Compar...

Embodiment 3

[0044] Example 3 Redox Activity Characterization of PBPA / SWCNTs / CdS / ITO Composite Electrode Made in the Present Invention

[0045] For the test of the redox activity of the PBPA / SWCNTs / CdS / ITO composite electrode constructed in Example 1, the specific steps are as follows:

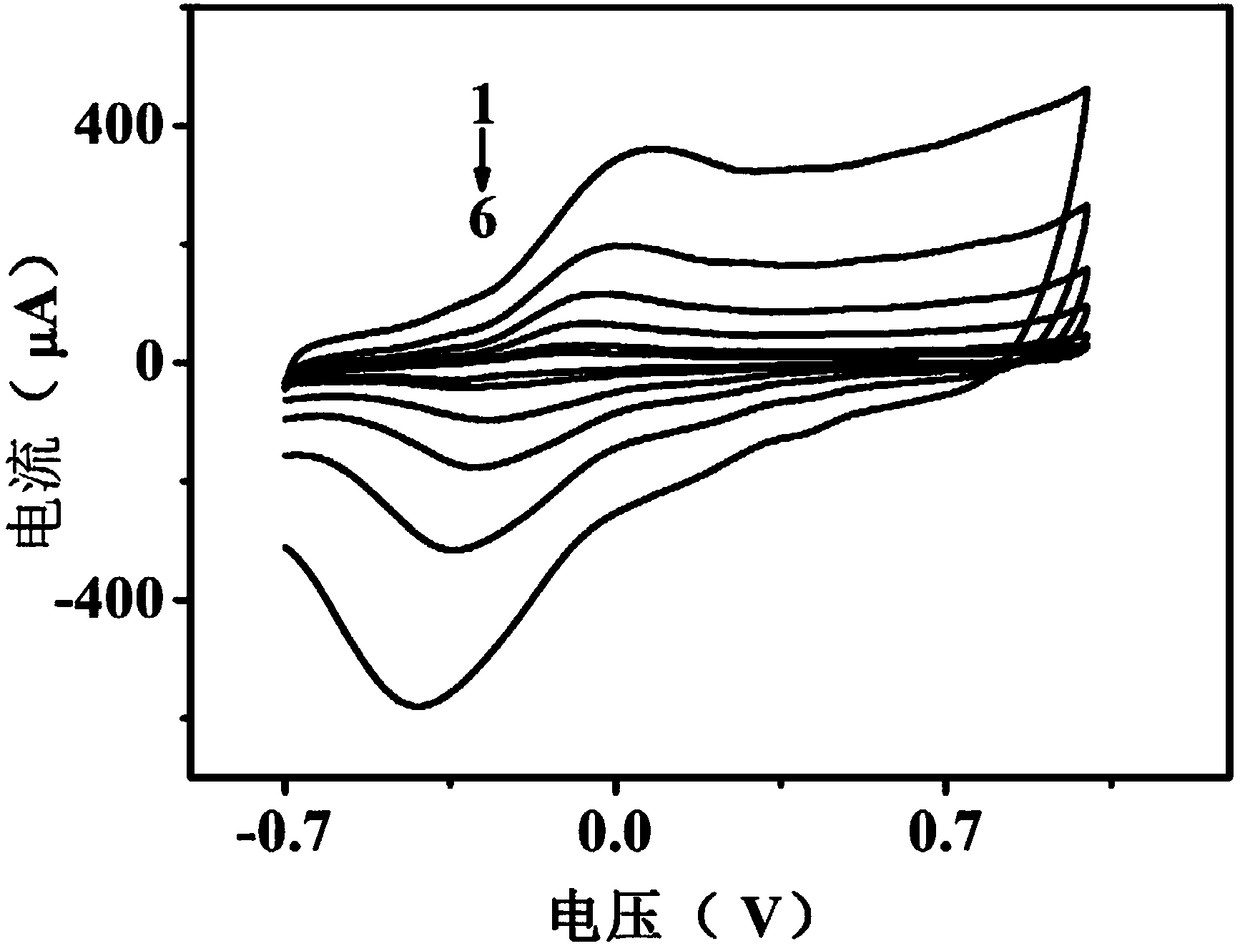

[0046] In the three-electrode system, the working electrode is PBPA / SWCNTs / CdS / ITO electrode, the counter electrode is titanium sheet, and the reference electrode is saturated calomel electrode. , 0.02, 0.01 (unit: V / s, corresponding image 3 and Figure 4 Under the conditions of No. 1 to 6) to measure the change of the current with the potential change, the cyclic voltammogram is obtained as shown in image 3 and Figure 4 .

[0047] from image 3 and Figure 4 It can be seen that bisphenol A can be directly oxidized by continuous differential pulse voltammetry scanning and its oxidation product can be fixed on the SWCNTs / CdS / ITO electrode, and the prepared PBPA / SWCNTs / CdS / ITO electrode has good red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| photocurrent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com