Preparation method and application of K1.33Mn8O16

A k1.33mn8o16, stirring reaction technology, used in the manufacture of hybrid/electric double-layer capacitors, electrolytic capacitors, electrical components, etc., to achieve highly reversible insertion-desorption behavior, low energy consumption, and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

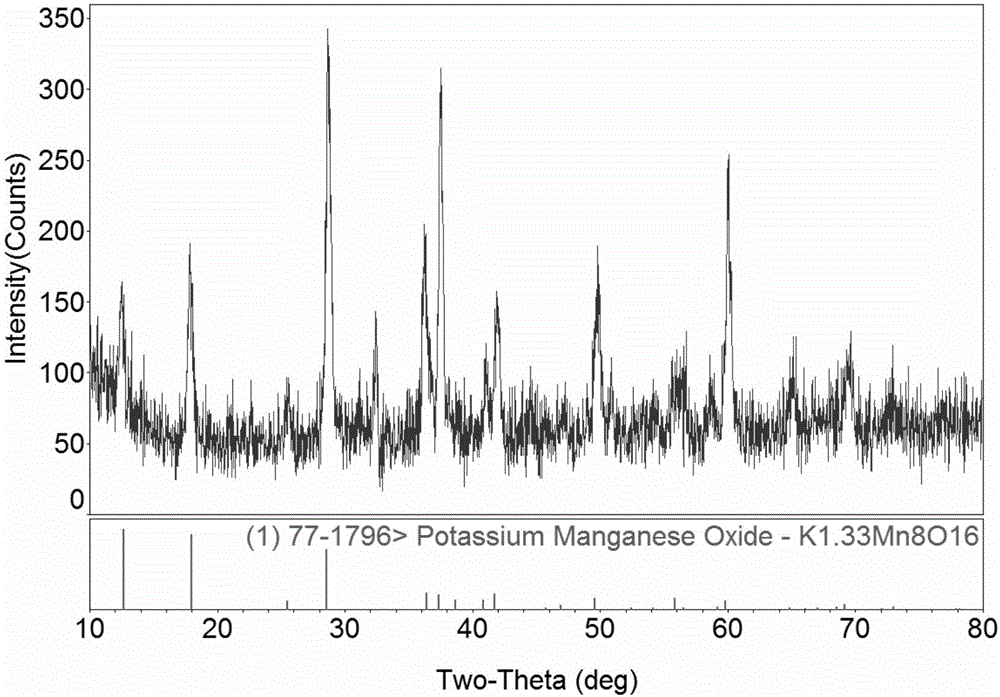

[0033] A certain amount of Mn(Ac) 2 ·H 2 O and citric acid (CA) were mixed so that the molar ratio of the substances was Mn / CA=1, 60 mL of distilled water was added, heated in a water bath at 70°C and magnetically stirred to fully dissolve the mixture. Then add a certain amount of KHCO to the solution 3 , so that the amount ratio of the substance is K / Mn=0.17, and the product obtained after fully stirring and dissolving is a colorless and transparent sol through the light transmission test of a laser pointer. The sol was dried at 110°C to obtain a white gel. Grind the gel above and place it in a 60cm×90cm porcelain boat and place the porcelain boat with the gel in a muffle furnace at 8°C min -1 The temperature was raised to 550°C at a certain rate and kept for 6 hours. After cooling to room temperature, take out the porcelain boat to obtain the product. The obtained product was subjected to phase analysis on an X-ray powder diffractometer (Dandong, Y-3000). The test condi...

Embodiment 2

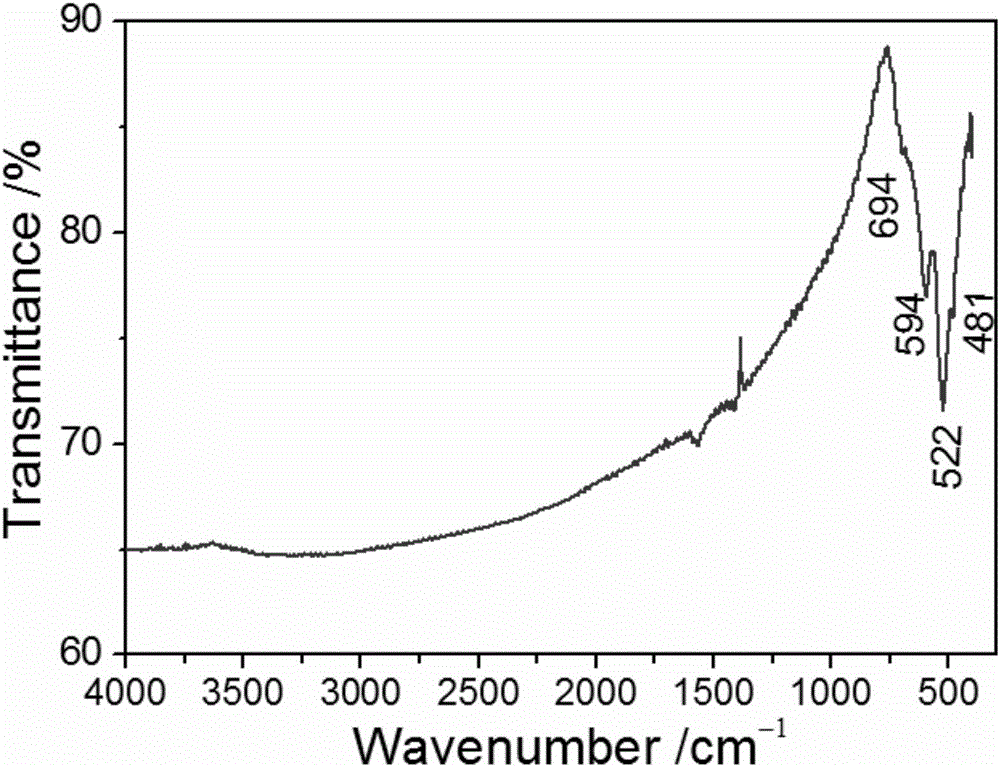

[0035] A certain amount of MnCO 3 and citric acid (CA) to make the molar ratio Mn / CA=1, add 70mL of distilled water, place in a 60°C water bath and heat with magnetic stirring to fully dissolve the mixture. Then add a certain amount of K to the solution 2 CO 3 , so that the material ratio K / Mn is 0.25, and the product obtained after fully stirring and dissolving is a colorless and transparent sol through the light transmission test of a laser pointer. The sol was dried at 110°C to obtain a white gel. Grind the gel above and place it in a 60cm×90cm porcelain boat and place the porcelain boat with the gel in a muffle furnace at 8°C min -1 The temperature was raised to 650°C at a certain rate and kept for 4 hours. After cooling to room temperature, take out the porcelain boat to obtain the product. The product was proved to be the same substance as the product in Example 1 by XRD analysis. The product was subjected to infrared spectroscopic analysis on an FT-IR spectrometer...

Embodiment 3

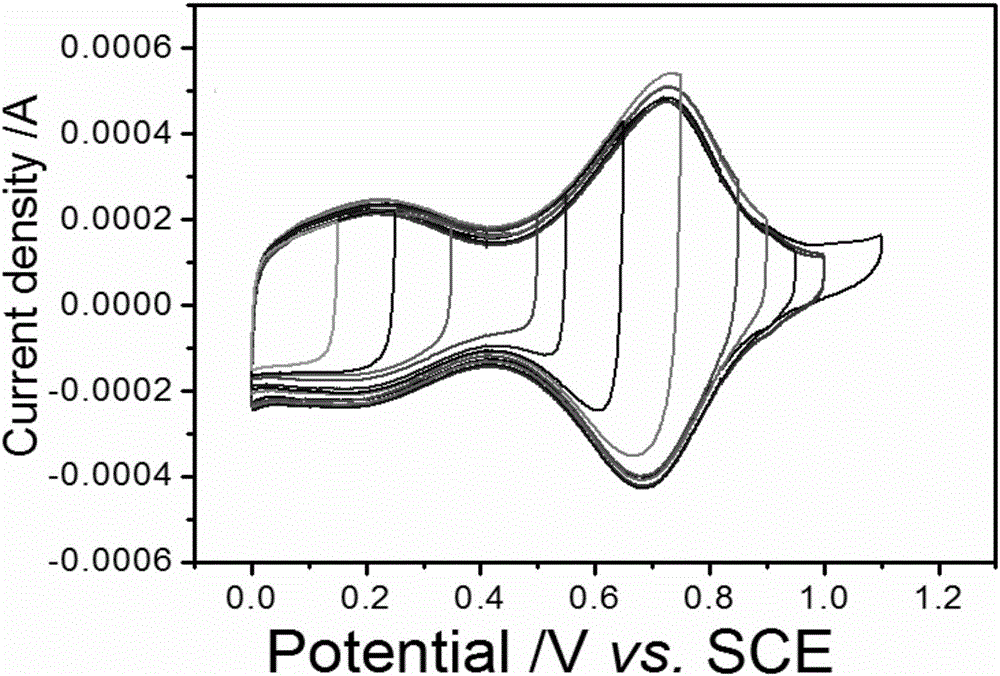

[0037] K prepared in Example 1 1.33 mn 8 o 16 Mix powder, acetylene black and polytetrafluoroethylene (PTFE) in a mass ratio of 80:15:5, add a small amount of distilled water and ethanol, and continue to stir until the mixture is in the shape of plasticine, and roll it into a thickness of about 10 μm. Film, cut the film into thin slices with a size of 1cm×1cm, press the thin slices with 300-mesh 316L stainless steel mesh under a pressure of 12MPa, and dry them in a vacuum oven at 120°C for 8 hours to make electrode sheets. With the platinum sheet electrode as the counter electrode and the saturated calomel electrode as the reference electrode, the prepared K 1.33 mn 8 o 16 The electrode is the working electrode, with 0.5mol L -1 Potassium sulfate solution was used as the electrolyte, and the CHI760d electrochemical workstation was used to set the potential scan rate to 1mV s -1 , respectively in 0~0.1V(vs.SCE), 0~0.2V(vs.SCE), 0~0.3V(vs.SCE), 0~0.5V(vs.SCE), 0~0.6V(vs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com