Ionic polymer metal composites (IPMC) electrochemistry driver, preparation method and application thereof

A driver and electrochemical technology, applied in the field of artificial muscles, can solve the problems that the deformation ability of the driver cannot be further improved, it is difficult to obtain IPMC devices, low electrochemical activity, etc., and achieve excellent electromechanical response performance, easy for large-scale production, The effect of fast response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

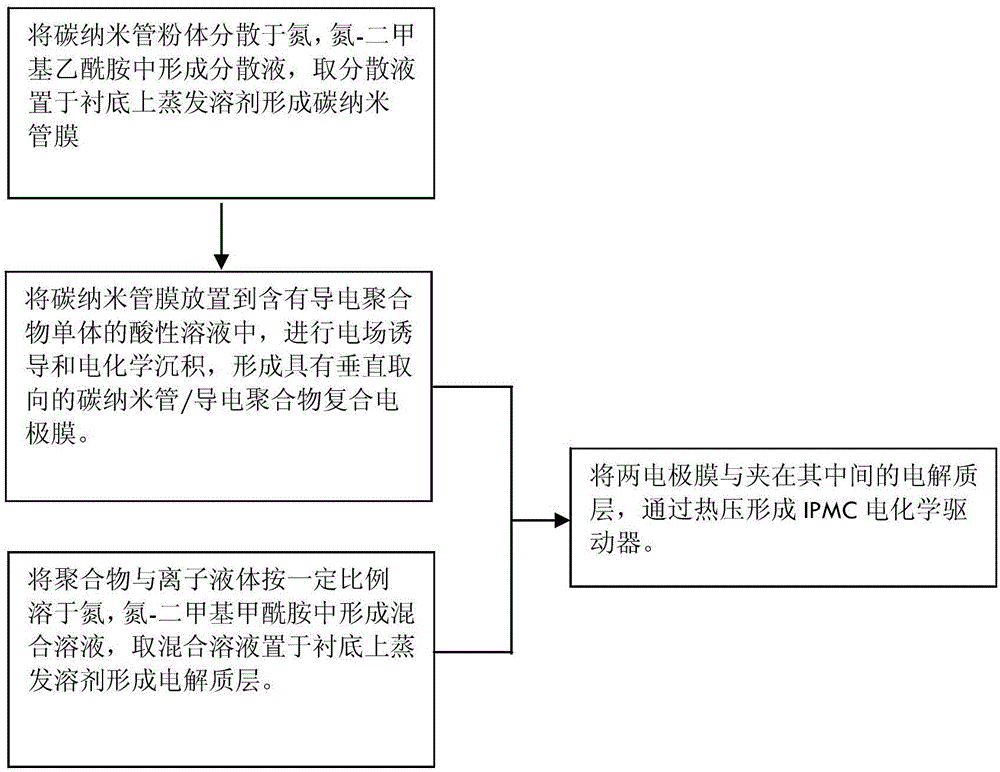

[0042] see figure 1 , in a more typical embodiment of the present invention, the preparation method may include the following steps:

[0043] S1. Preparation of carbon nanotube / conductive polymer composite electrode film: disperse carbon nanotube powder in nitrogen, nitrogen-dimethylacetamide, etc., and a solvent to form a dispersion liquid, take the dispersion liquid and place it on the substrate to evaporate the solvent Forming a carbon nanotube film; placing the carbon nanotube film in an acidic solution containing a conductive polymer monomer for electric field induction and electrochemical deposition to form a carbon nanotube / conductive polymer composite electrode film with vertical orientation;

[0044]S2. Prepare the polymer electrolyte layer supporting the ionic liquid: dissolve the polymer and the ionic liquid in a certain proportion in nitrogen, nitrogen-dimethylformamide to form a mixed solution, take the mixed solution and place it on the substrate to evaporate the...

Embodiment 1

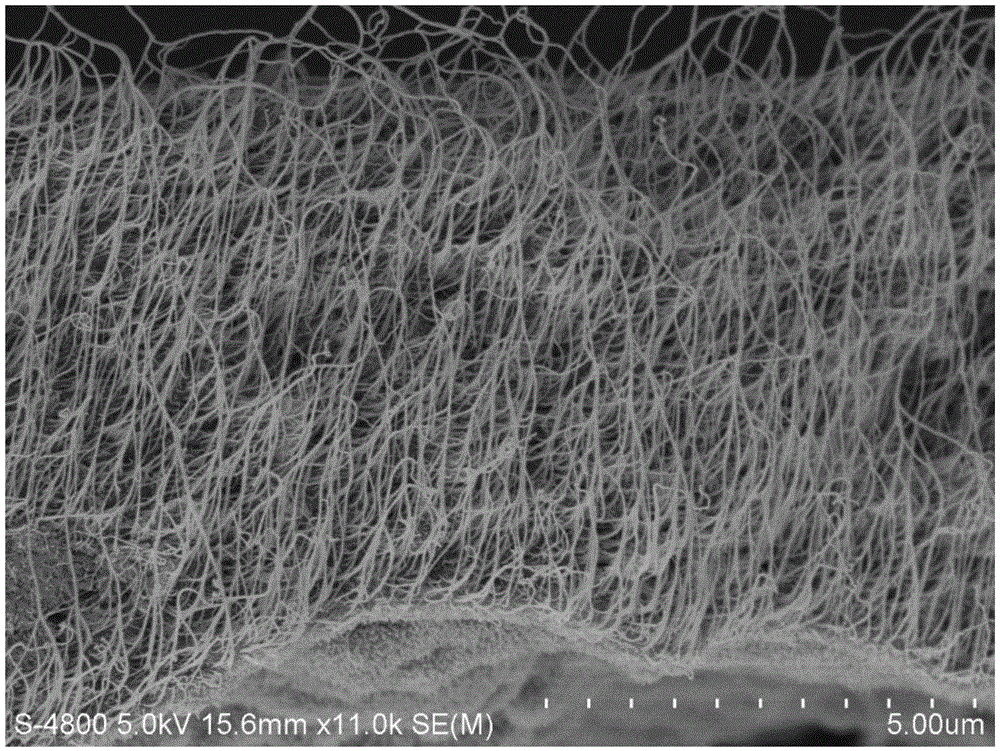

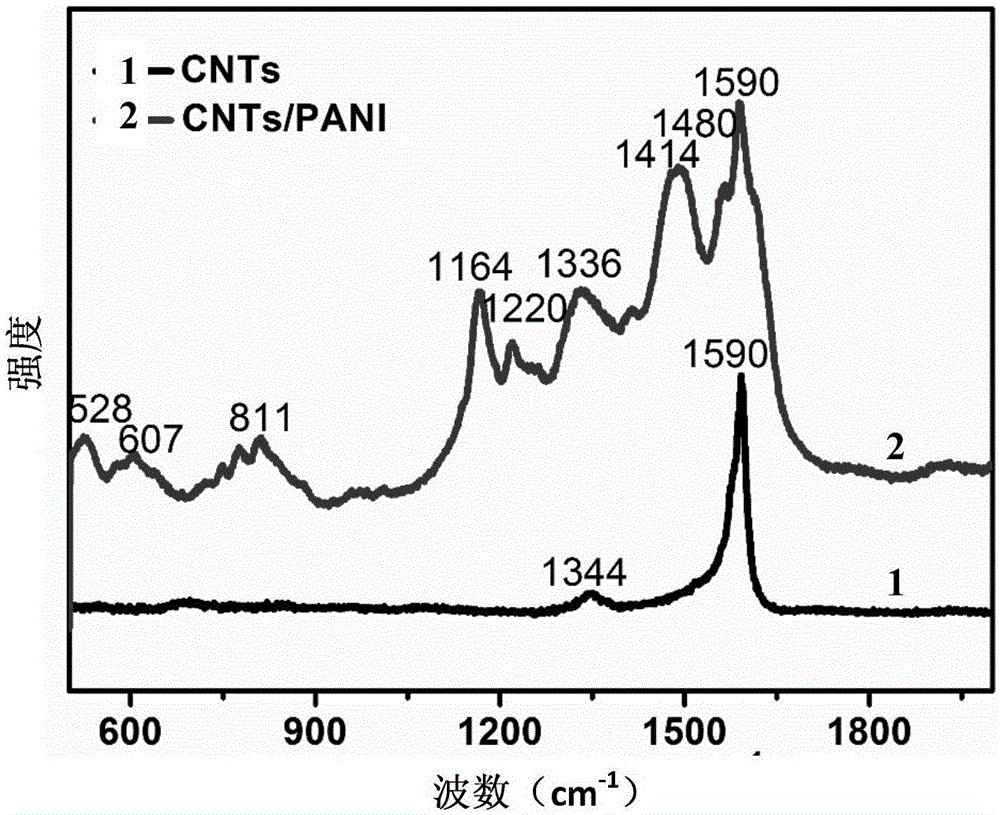

[0053] Weigh 100 mg of single-walled carbon nanotube powder and disperse it in 40 ml of nitrogen, nitrogen-dimethylacetamide solvent, crush the cells and sonicate for 30 min, and prepare a dispersion with a concentration of 2.5 mg / ml. Take 3ml of carbon nanotube dispersion and put it into a 75x25cm 2 On the glass substrate, after drying at a low temperature of 25°C, it was placed in a vacuum oven at 80°C for 1 day to obtain a carbon nanotube film. Afterwards, a three-electrode system was constructed to use electric field induction and electrochemical oxidation polymerization to vertically align carbon nanotubes / conductive polymer composites: the carbon nanotube film was used as the working electrode, the saturated Ag / AgCl solution was used as the reference electrode, and the Pt sheet was used as the auxiliary electrode. The electrode, the solute aniline monomer (0.1M) and the solvent perchloric acid (1M) are the electrolyte; the constant current mode is used to conduct electri...

Embodiment 2

[0056] Weigh 40 mg of single-walled carbon nanotube powder and disperse it in 80 ml of nitrogen, nitrogen-dimethylacetamide solvent, crush the cells and sonicate for 30 min to form a dispersion with a concentration of 0.5 mg / ml. Take 15ml of carbon nanotube dispersion and divide it into 5 times, and put it into a 75x25cm 2 On the aluminum foil substrate, after drying at 120°C, put it in a vacuum oven at 80°C for 1 day to obtain a carbon nanotube film. Afterwards, a three-electrode system was constructed to use electric field induction and electrochemical oxidation polymerization to vertically align carbon nanotubes / conductive polymer composites: the carbon nanotube film was used as the working electrode, the saturated Ag / AgCl solution was used as the reference electrode, and the Pt sheet was used as the auxiliary electrode. The electrode, the solute pyrrole monomer (0.01M) and the solvent hydrochloric acid (0.1M) are the electrolyte; the constant current mode is used to conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com