Processing formula and manufacture method of exogenous water free potato noodles

A technology of potato noodles and a production method, which is applied to the functions of food ingredients, food ingredients as taste improvers, food science, etc., can solve the problems of high energy consumption in the processing process, and achieve the goals of improving efficiency, rich sources of raw materials, and reducing loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

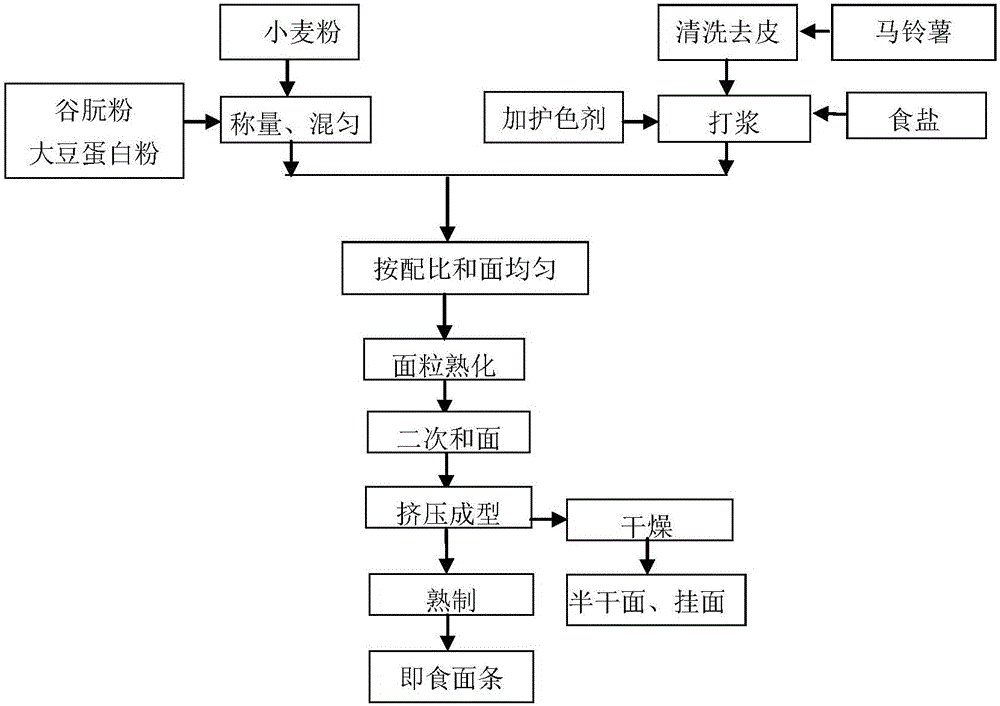

Image

Examples

Embodiment 1

[0029] A recipe for processing potato noodles without adding exogenous water, made from the following raw materials in parts by weight:

[0030] 90 parts of common wheat flour, 40 parts of fresh potato, 2 parts of gluten flour, 2 parts of soybean protein powder, 0.05 part of color protectant, 1 part of table salt.

[0031] The color-protecting agent is one of sodium ascorbate, sodium erythorbate, calcium chloride, citric acid or a combination thereof.

[0032] A method for preparing potato noodles without adding exogenous water according to claim 1, characterized in that the steps comprise:

[0033] 1) After peeling and washing the potatoes, cut 40 parts of the potatoes into small pieces by weight, and evenly stir 0.05 parts of the color-protecting agent with the potato pieces;

[0034] 2) After beating the potato pieces stirred in step 1, add 1 part of salt;

[0035] 3) 90 parts of wheat flour, 2 parts of gluten powder and 2 parts of soybean protein powder are uniformly sti...

Embodiment 2

[0051] A recipe for processing potato noodles without adding exogenous water, made from the following raw materials in parts by weight:

[0052] 100 parts of common wheat flour, 55 parts of fresh potato, 4 parts of gluten flour, 3 parts of soybean protein powder, 0.20 parts of color protectant, 3 parts of table salt.

[0053] The color-protecting agent is one of sodium ascorbate, sodium erythorbate, calcium chloride, citric acid or a combination thereof.

[0054]A method for preparing potato noodles without adding exogenous water according to claim 1, characterized in that the steps comprise:

[0055] 1) After peeling and washing the potatoes, cut 55 parts of the potatoes into small pieces by weight, and evenly stir 0.20 parts of the color-protecting agent with the potato pieces;

[0056] 2) After beating the potato pieces stirred in step 1, add 3 parts of salt;

[0057] 3) 100 parts of wheat flour, 4 parts of gluten powder and 3 parts of soybean protein powder are uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com