Temperature-sensitive type skin wound dressing as well as preparation method and applications thereof

A temperature-sensitive, skin wound technology, applied in the fields of medical science, absorbent pads, bandages, etc., to achieve the effect of promoting wound repair, good repeatability, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

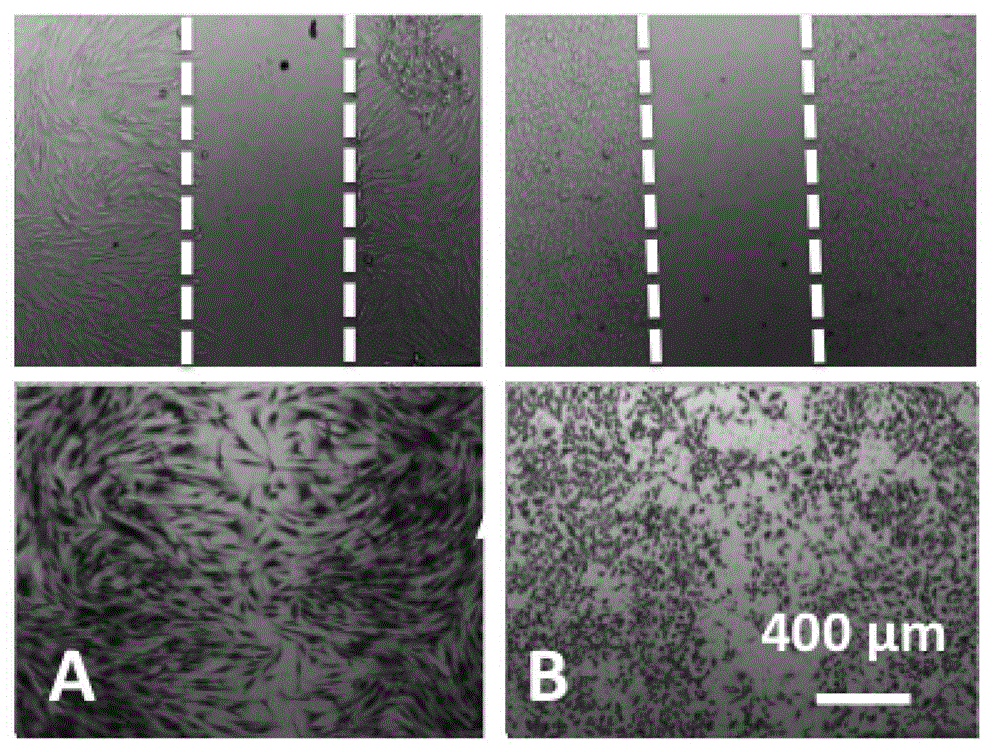

[0057] In one example, the preparation method of temperature-sensitive skin wound dressing of the present invention comprises:

[0058] Dissolving agar or agarose or a mixture of the two in hot water at 65-95°C to obtain solution A, wherein the mass percentage of the agar or agarose or the mixture of the two is 1-4%;

[0059] Dissolving alginate powder at room temperature to obtain solution B, wherein the mass percentage of alginate is 1% to 4%;

[0060] Mix solution A and solution B at a ratio of 1:1 at 45-60°C, and stir evenly. The resulting mixed solution can maintain a solution state at a temperature above 45°C, and it can be formed after cooling down to around body temperature for about 1-5 minutes. stabilized hydrogels;

[0061] Add bioactive glass in the form of 1-20% by mass to the obtained temperature-sensitive hydrogel solution at 45-60°C, mix evenly, and the obtained mixed solution can maintain a solution state at a temperature above 45°C , Cool down to around bod...

Embodiment 1

[0068] The product prepared in this example is a temperature-sensitive hydrogel containing 1% agarose, 1% sodium alginate and 1% bioactive glass. The specific product preparation process is as follows:

[0069] 1. Dissolve 2% agarose in deionized water at 95°C;

[0070] 2. Dissolve sodium alginate powder with a mass percentage of 2% at room temperature;

[0071] 3. Mix the above two solutions at a ratio of 1:1 at 55°C and stir evenly;

[0072] 4. Change the chemical composition to CaO 24.5%, SiO 2 45%,Na 2 O 24.5%, P 2 o 5 6%, bioactive glass with a particle size of less than 100 microns is added to the temperature-sensitive composite hydrogel solution at a mass percentage of 1%, and mixed evenly.

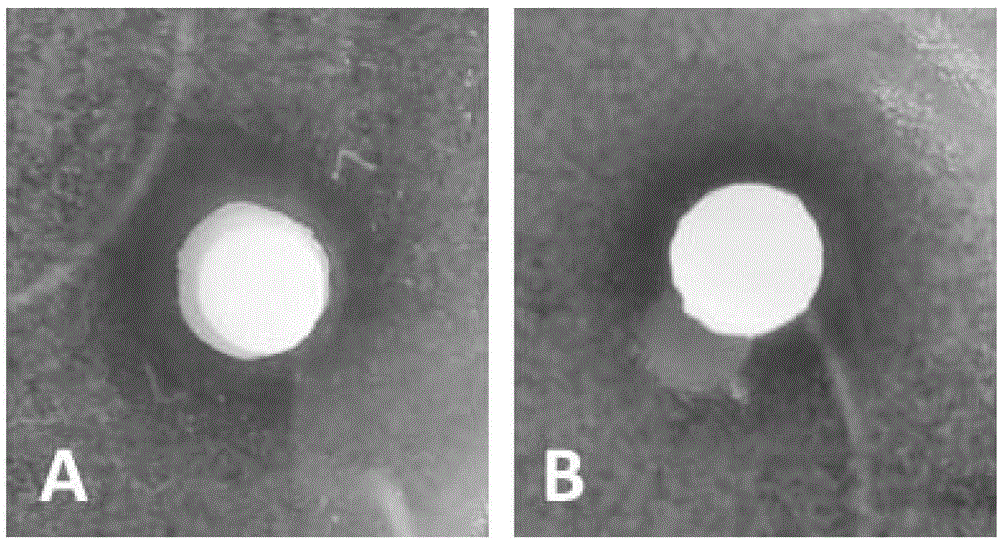

[0073] The mixed solution obtained from the production process of the above product is temperature-sensitive. It remains in a solution state at a temperature above 45°C, and a stable hydrogel can be formed when the temperature is lowered to around body temperature for 1 min...

Embodiment 2

[0075] The mixed solution was prepared by the same method as in Example 1, except that the mass percentage of bioactive glass was 5%.

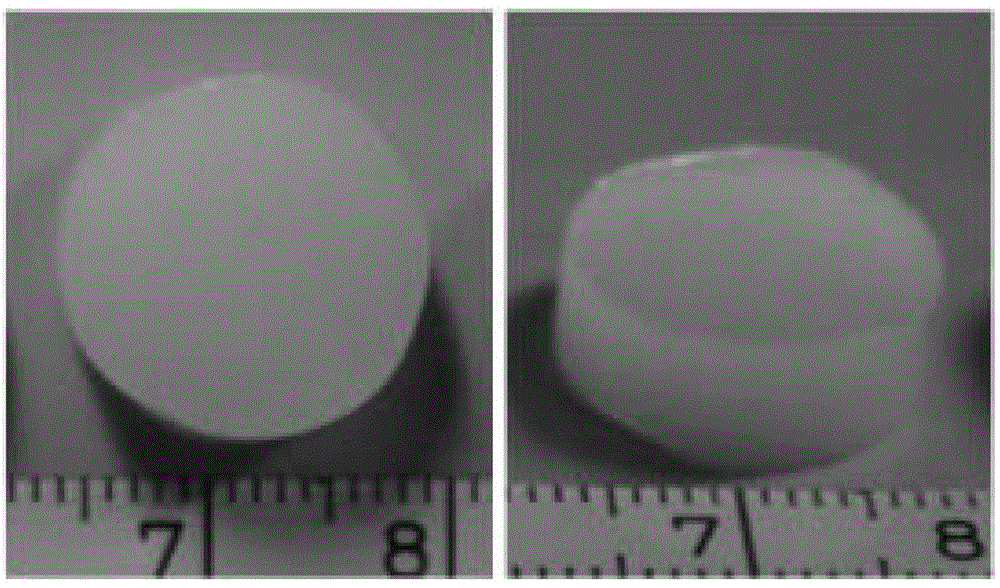

[0076] The prepared mixed solution is kept in a solution state at a temperature above 45° C., injected into a mold, and cooled to prepare a hydrogel dressing with a diameter of 6 mm and a thickness of 1 to 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com