A kind of forward and reverse flushing piston type water storage, micro-wastewater RO system and membrane flushing method

A technology of forward and reverse washing and water storage, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the RO system cannot be used for domestic water purification treatment and affects the use effect of the RO system. , blocking membrane and other problems, to achieve the effect of improving water saving effect, ensuring membrane filtration efficiency, and improving flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

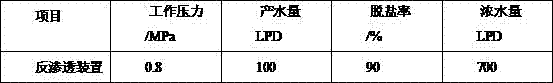

[0055] The water purifier of a reverse osmosis device in a residential area in Shandong, with an initial design capacity of 300L / day, is operated by a conventional flushing control system, and the membrane is cleaned regularly. After half a year of use, the initial water production of the system is 100L / day. The operating parameters before the transformation are as follows Table 1:

[0056] Table 1 Operating parameters before transformation

[0057]

[0058] Due to the fouling problem caused by long-term operation, the parameters of the reverse osmosis system such as water production and desalination rate are not as good as before. However, using the forward-backwash micro-wastewater RO system of the present invention, under the same environment, the operating parameters are as follows in Table 2:

[0059] Table 2 Operating parameters after modification

[0060]

[0061] Adopting the forward-backwash micro-wastewater RO system of the present invention greatly increases ...

Embodiment 2

[0063] A household water reverse osmosis system in the living area of a group, the design standard is 1500L / day, one-stage two-stage operation, a conventional backwash system is used for automatic control of membrane flushing, the system has been in operation for 8 months, the membrane modules are seriously polluted, and the operating cost and effect are not up to the mark According to the requirements, the operating parameters of the system before the transformation are shown in Table 3:

[0064] Table 3 Operating parameters before transformation

[0065]

[0066] Adopting the forward-backwashing micro-wastewater RO system of the present invention, through the double flushing system and the automatic control system, the service life and flushing effect of the RO membrane are greatly improved, the membrane inlet pressure and fouling degree are reduced, and the operating energy consumption is reduced.

[0067] Table 4 Operating parameters after modification

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com