Production technology of potassium sulfate

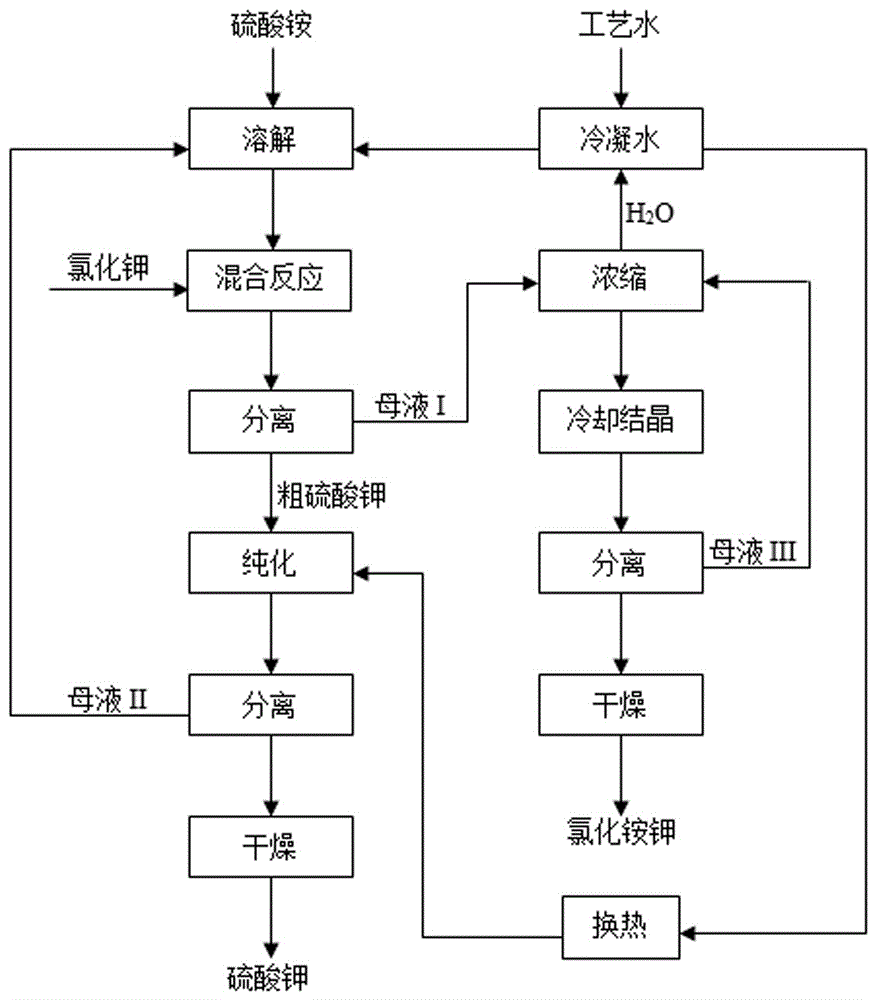

A production process, potassium sulfate technology, applied in the production of potassium sulfate by using ammonium sulfate and potassium chloride, and in the field of potassium sulfate production, can solve problems such as complex process, achieve simple process equipment, convenient operation, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Implementation 1: Dissolve ammonium sulfate with water in the reaction tank, then add potassium chloride with a molar ratio of 1:1.5 to ammonium sulfate in the reaction tank, control the reaction temperature at 65°C, and react for 1h under the condition of sufficient stirring. The slurry is separated by a centrifuge to obtain crude potassium sulfate and mother liquor I, and after adding water with a mass ratio of 0.5:1 to the crude potassium sulfate to purify the crude potassium sulfate, it enters the centrifuge for centrifugal separation to obtain the product potassium sulfate and mother liquor II, and obtains The mother liquor Ⅰ enters the concentration device to concentrate to a specific gravity of 1.4g / ml, then cools to 30°C to crystallize, and then centrifuges to obtain the mother liquor Ⅲ and ammonium potassium chloride, and then dries to obtain the by-product potassium ammonium chloride, and the mother liquor Ⅱ returns to the reaction The tank is used to dissolve ...

Embodiment 2

[0023] Implementation 2: Dissolve ammonium sulfate in the reaction tank with water, then add potassium chloride with a molar ratio of 1:2 to ammonium sulfate in the reaction tank, control the reaction temperature at 80°C, and react for 1.5h under the condition of sufficient stirring. After the reaction The slurry is separated by a centrifuge to obtain crude potassium sulfate and mother liquor I. After adding water with a mass ratio of 1:1 to the crude potassium sulfate to the crude potassium sulfate for purification, it enters the centrifuge for centrifugal separation to obtain the product potassium sulfate and mother liquor II. The obtained mother liquor Ⅰ enters the concentrator and concentrates to a specific gravity of 1.35g / ml, then cools to 30°C to crystallize, and then centrifuges to obtain the mother liquor Ⅲ and ammonium potassium chloride. After drying, the by-product potassium ammonium chloride can be obtained, and the mother liquor Ⅱ returns to The reaction tank is u...

Embodiment 3

[0025] Implementation 3: Dissolve ammonium sulfate in the reaction tank with water, then add potassium chloride with a molar ratio of 1:2 to ammonium sulfate in the reaction tank, control the reaction temperature at 65°C, and react for 1h under the condition of sufficient stirring. The slurry is separated by a centrifuge to obtain crude potassium sulfate and mother liquor I, and after adding water with a mass ratio of 1.2:1 to the crude potassium sulfate to the crude potassium sulfate for purification, it enters the centrifuge for centrifugal separation to obtain the product potassium sulfate and mother liquor II, and obtains The mother liquor Ⅰ enters the concentration device to concentrate to a specific gravity of 1.4g / ml, then cools to 30°C to crystallize, and then centrifuges to obtain the mother liquor Ⅲ and ammonium potassium chloride, and then dries to obtain the by-product potassium ammonium chloride, and the mother liquor Ⅱ returns to the reaction The tank is used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com