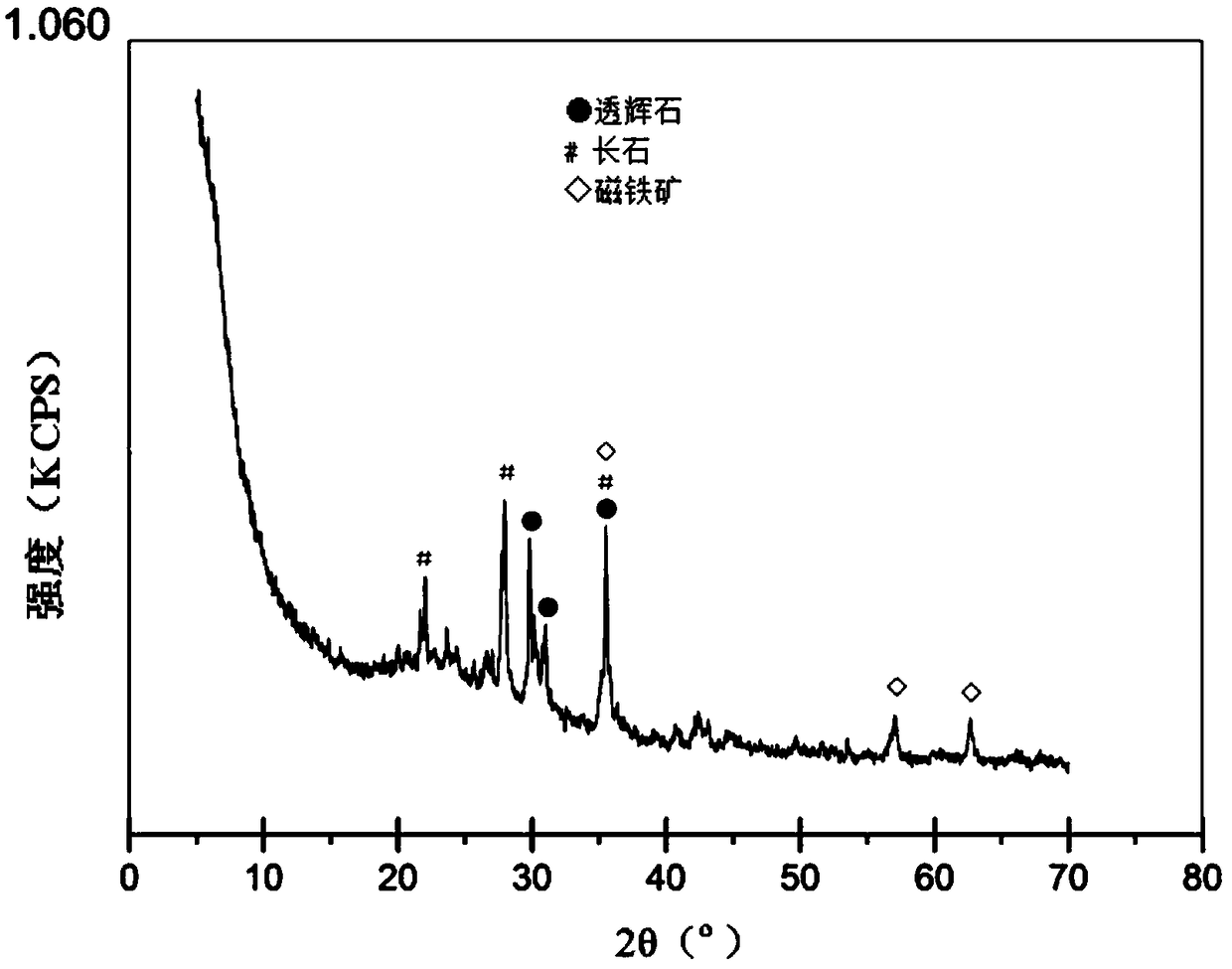

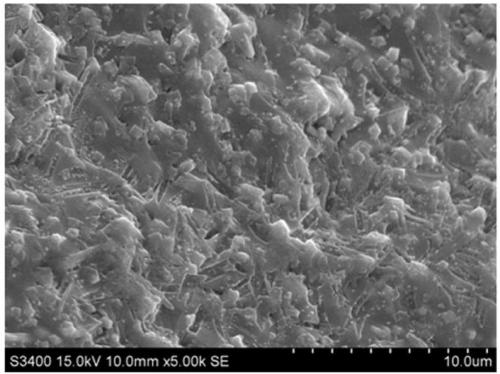

Diopside and feldspar main crystal phase glass-ceramics and preparation method thereof

A technology of glass-ceramic and main crystalline phase, applied in the field of building decoration materials, can solve the problems of easy warping and deformation of plates and high porosity, and achieve the effects of excellent acid and alkali resistance, lower melting temperature and lower raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of diopside and feldspar main crystal phase glass-ceramics, specifically comprising the following steps:

[0034] 1) Batching and mixing: raw materials are weighed according to the proportioning ratio, and each component includes: 30 parts of iron tailings, SiO 2 49 copies, Al 2 o 3 8 parts, CaO 3 parts, MgO 2 parts, Na 2 CO 3 4 parts, ZnO 2 parts, B 2 o 3 1 part; after mixing the weighed raw materials evenly, put them into a vibrating mill and grind to no less than 95wt% below 200 mesh to obtain the mixed raw materials;

[0035] 2) Melting and water quenching treatment: put the obtained mixed raw material into a corundum crucible, put it into a silicon molybdenum rod high-temperature electric furnace, heat it to 1450 ° C for 2 hours, and perform melting treatment, pour the obtained molten liquid into cold water for water quenching treatment, and then drying the obtained glass pellets, and grinding to a particle size of less than 100 mesh to o...

Embodiment 2

[0040] A preparation method of diopside and feldspar main crystal phase glass-ceramics, specifically comprising the following steps:

[0041] 1) Batching and mixing: raw materials are weighed according to the proportioning ratio, and each component includes: 30 parts of iron tailings, SiO 2 49 copies, Al 2 o 3 8 parts, CaO 3 parts, MgO 2 parts, Na 2 CO 3 4 parts, ZnO 2 parts, B 2 o 3 1 part; after mixing the weighed raw materials evenly, put them into a vibrating mill and grind to no less than 95wt% below 200 mesh to obtain the mixed raw materials;

[0042] 2) Melting and water quenching treatment: put the obtained mixed raw materials into a corundum crucible, put them into a silicon-molybdenum rod high-temperature electric furnace, heat to 1450 ° C for 2.5 hours, and carry out melting treatment, and pour the obtained molten liquid into cold water for Water quenching treatment, then drying the obtained glass pellets, and grinding to a particle size of less than 100 mesh ...

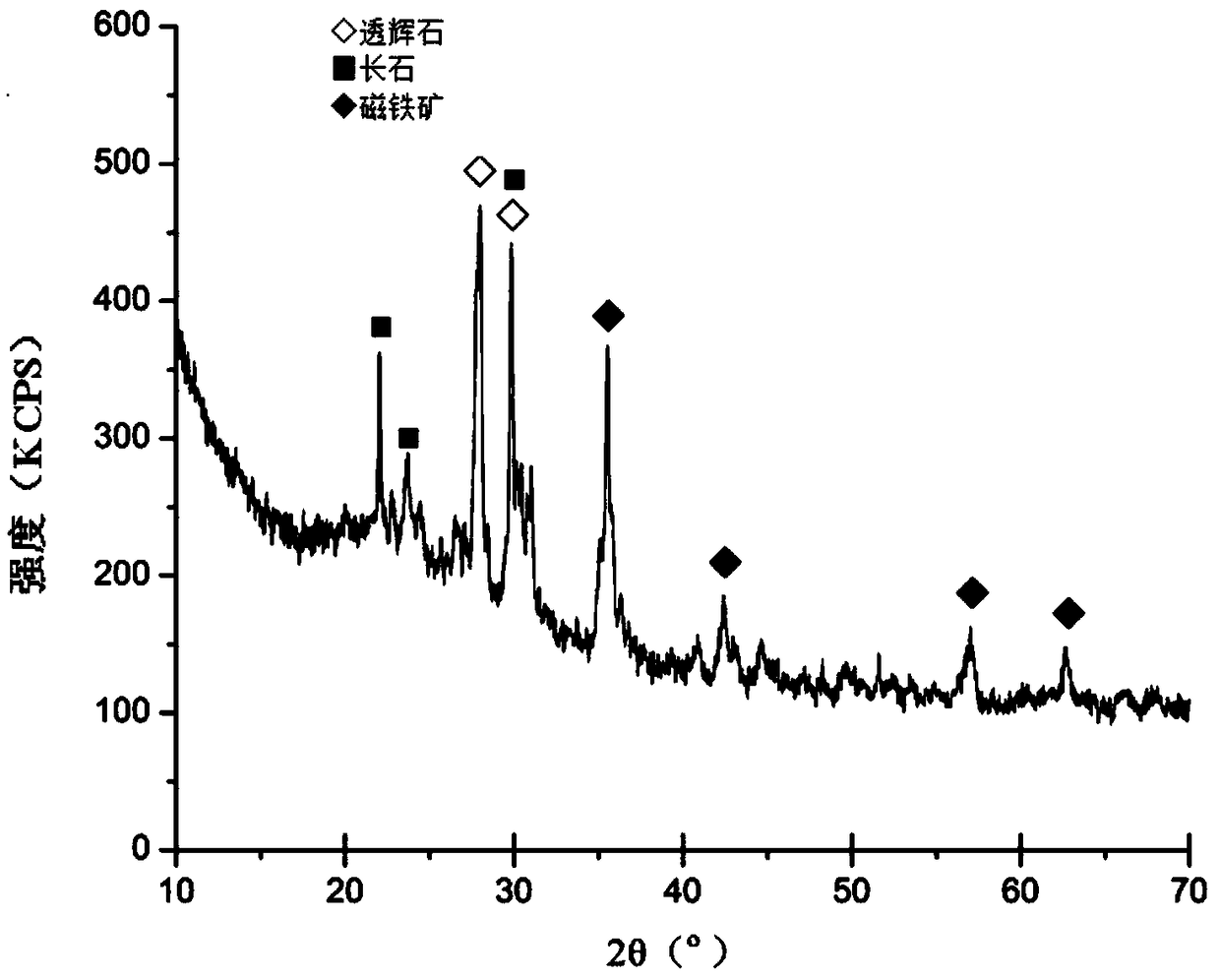

Embodiment 3

[0047] A preparation method of diopside and feldspar main crystal phase glass-ceramics, specifically comprising the following steps:

[0048] 1) Batching and mixing: raw materials are weighed according to the ratio, and each component includes: 30 parts of iron tailings, 6 parts of calcite, 16 parts of potassium feldspar, 39 parts of quartz, 2 parts of MgO, Al 2 o 3 5 parts, ZnO2 parts, B 2 o 3 1 part; after mixing the weighed raw materials evenly, put them into a vibrating mill and grind to no less than 95wt% below 200 mesh to obtain the mixed raw materials;

[0049] 2) Melting and water quenching treatment: put the obtained mixed raw material into a corundum crucible, put it into a silicon-molybdenum rod high-temperature electric furnace, heat it to 1450 ° C for 2 hours, and carry out melting treatment, and pour the obtained molten liquid into cold water for Water quenching treatment, then drying the obtained glass pellets, and grinding to a particle size of less than 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com