Biological purifying process of unconventional gas

A technology of unconventional natural gas and process method, applied in the field of unconventional natural gas resource purification, can solve the problems of complex process, secondary pollution and high energy consumption, and achieve the effects of stable gas quality, good purification effect and high purification purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

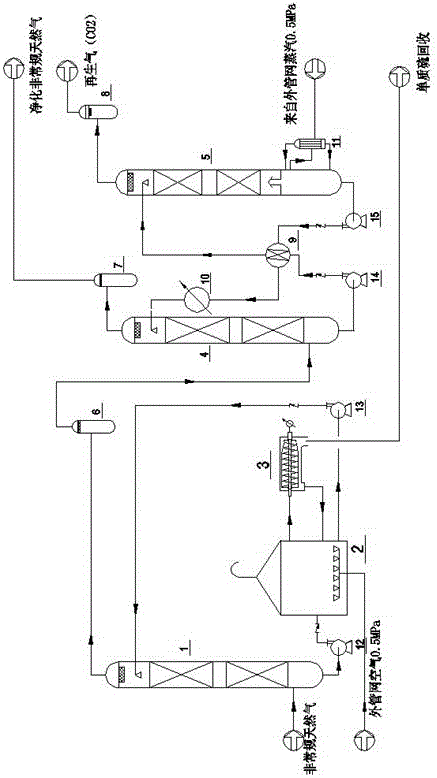

Image

Examples

Embodiment 1

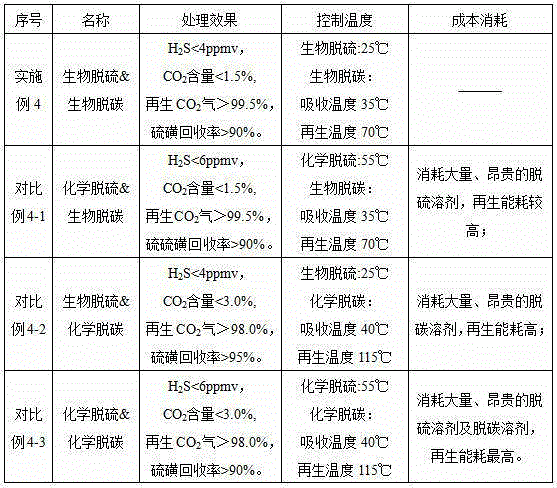

[0035] Example 1: Biogas biological desulfurization & biological decarbonization process

[0036] Biogas to be purified from biomass fermentation in a biogas plant, with a processing capacity of 30,000 Nm 3 / h, the pressure is 3.0 KPa, CO 2 35%, H 2 S 0.5%.

[0037] Using the present invention, the absorbent for biological desulfurization is Na 2 CO 3 / NaHCO 3 The pH of the buffer solution is 8.7, the concentration of the biological desulfurization catalyst Thiobacillus naples is 300mg / L, the biological regeneration temperature is 30℃; the biological decarburization absorbent is a mixture of 45% glutamic acid and 5% piperazine, biological decarburization The concentration of the catalyst carbonic anhydrase is 300mg / L, the decarburization absorption temperature is 40°C, and the desorption temperature is 80°C. Purifying temperament H 2 S 2 Content is less than 1.5%, regenerated CO 2 The content is more than 99.5%, and the sulfur recovery rate is 95%.

Embodiment 2

[0038] Example 2: CBM biological desulfurization & biological decarbonization process

[0039] The processing capacity of CBM to be purified is 50,000 Nm 3 / h, the pressure is 1.2MPa, CO 2 28%, H 2 S 5.0%.

[0040] Using the present invention, the absorbent for biological desulfurization is Na 2 CO 3 / NaHCO 3 The pH of the buffer solution is 9.0, the concentration of the biological desulfurization catalyst Thiobacillus denitrificans is 1000 mg / L, the biological regeneration temperature is 35 ℃; the biological decarbonization absorbent is a mixture of 45% valine and 5% piperazine, biological desulfurization The carbon catalyst carbonic anhydrase concentration is 1200mg / L, the decarburization absorption temperature is 40°C, and the desorption temperature is 75°C. Purifying temperament H 2 S 2 Content is less than 1.5%, regenerated CO 2 The content is more than 99.5%, and the sulfur recovery rate is 95%.

Embodiment 3

[0041] Example 3: Natural gas hydrate biological desulfurization & biological decarbonization process

[0042] The processing capacity of natural gas hydrate to be purified is 40,000 Nm 3 / h, the pressure is 5.0MPa, CO 2 35%, H 2 S 1.5%.

[0043] Using the present invention, the absorbent for biological desulfurization is Na 2 CO 3 / NaHCO 3 The pH value of the buffer solution is 8.8, the concentration of the biological desulfurization catalyst Thiobacillus excretion is 600mg / L, and the biological regeneration temperature is 30℃; the biological decarbonization absorbent is a mixture of 45% dimethylglycine and 5% piperazine. The carbonic anhydrase concentration of the decarburization catalyst is 800 mg / L, the decarburization absorption temperature is 35°C, and the desorption temperature is 75°C. Purifying temperament H 2 S 2 Content is less than 1.5%, regenerated CO 2 The content is more than 99.5%, and the sulfur recovery rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com