Technology for normal-temperature wet-process harmless treatment of arsenic soda slag

A technology of harmless treatment and arsenic-alkali residues, which can be applied to the improvement of process efficiency, chemical instruments and methods, and the removal of solid waste, etc., and can solve the problems of low product quality, difficult automation of equipment, and difficult waste water treatment. Achieve the effect of good process stability, guarantee of occupational hygiene, and improvement of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

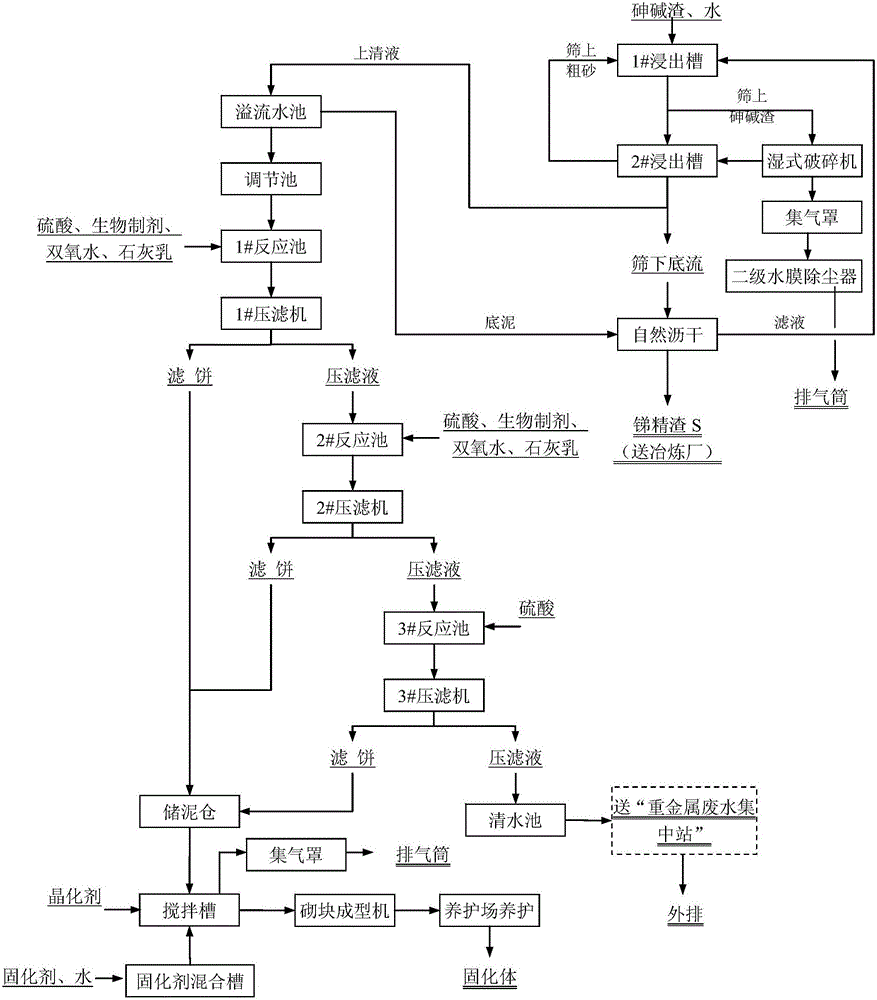

Method used

Image

Examples

Embodiment 1

[0031] Crush the arsenic-alkali slag containing 16.10% arsenic and 22.99% antimony to ensure that the particle size is below 5mm, weigh 100g, add 400g water and stir, and react at a temperature of about 25°C for 1 hour. Then filter and dry the filter residue, the weight of the residue is 32g, the grades of antimony and arsenic in the residue are analyzed, and they are respectively: antimony 69.0%, arsenic 1.5%, the calculation shows that the recovery rate of antimony reaches 96.0%, and the leaching rate of arsenic reaches 97.0%.

Embodiment 2

[0033] Grind arsenic-alkali residue containing 15.97% arsenic and 20.10% antimony, sieve to ensure that the particle size is below 5mm, weigh 100g, add 400g water and stir, and react at a temperature of about 25°C for 1 hour. Then filter and dry the filter residue, the weight of the residue is 29g, the grades of antimony and arsenic in the residue are analyzed, they are respectively: antimony 66.9%, arsenic 1.5%, the calculation shows that the recovery rate of antimony reaches 96.5%, and the leaching rate of arsenic reaches 97.3%.

Embodiment 3

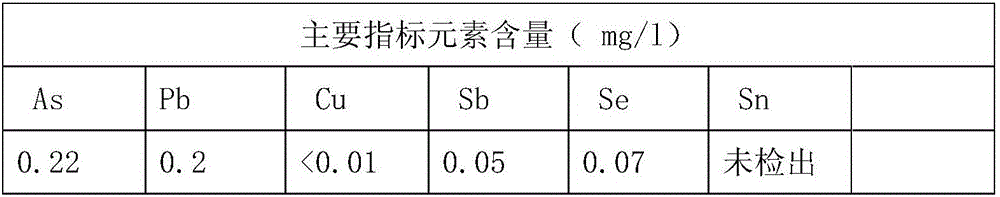

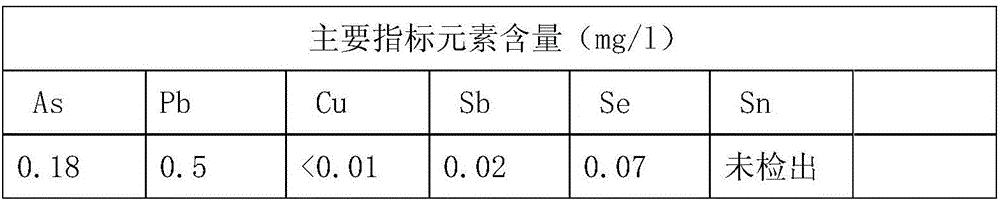

[0035] First add 20 g of concentrated sulfuric acid to the obtained high-arsenic leach solution of Example 1 (after adding the acid solution, its pH value is 2-3), then add 6 g of biological preparations, stir for 10 minutes, then add 1.6 g of industrial hydrogen peroxide, stir for 10 minutes, Finally, milk of lime was added to adjust the pH value to 14, and filtered to obtain a section of effluent and high-arsenic slag. The obtained section of effluent was firstly added with 4g of concentrated sulfuric acid, then 4g of biological agent, stirred for 10 minutes, and then 1.6g of industrial hydrogen peroxide, stirred for 10 minutes, and finally Add lime milk to adjust the pH value to 14, and filter to obtain the second-stage effluent and high-arsenic slag. The main comprehensive indicators of the second-stage effluent:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com