Large single crystal double layer graphene and the preparation method thereof

A technology of single-layer graphene and double-layer graphene, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low coverage, small area and poor quality of double-layer graphene, and achieve improved The effect of growth efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

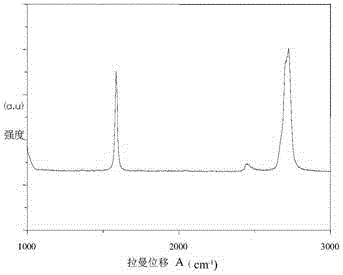

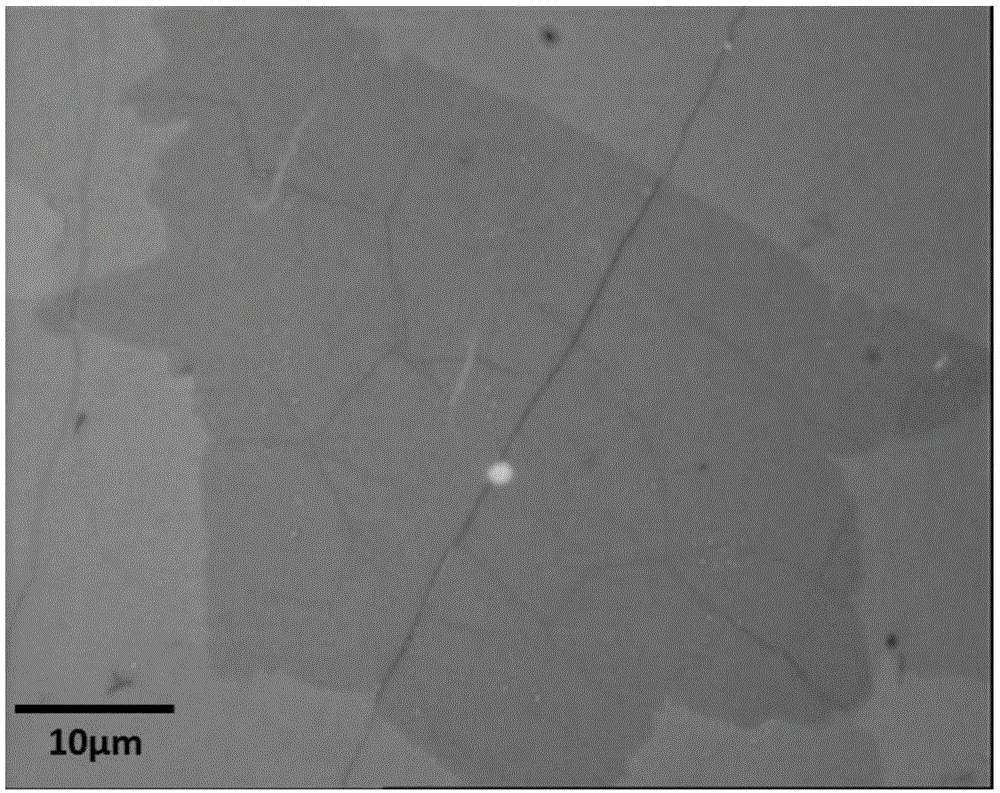

[0039] Embodiment 1, the bilayer graphene that is coated with the silicon substrate of 300nm silicon dioxide growth

[0040] Follow the steps below to grow bilayer graphene on a silicon substrate coated with 300nm silicon dioxide:

[0041] (1) Preparation of single-layer graphene and transfer

[0042] Using chemical vapor deposition equipment, based on the optimized growth conditions on the copper substrate, first obtain high-quality single-layer graphene, use wet transfer, first spin-coat PMMA glue on the single-layer graphene copper sheet, and bake the glue After 30 minutes, use ammonium persulfate to remove the copper sheet, pick up the film with a silicon substrate, and let it air-dry overnight. Then use acetone to remove the PMMA glue on the surface of the sample to obtain a single-layer graphene film transferred on the silicon substrate.

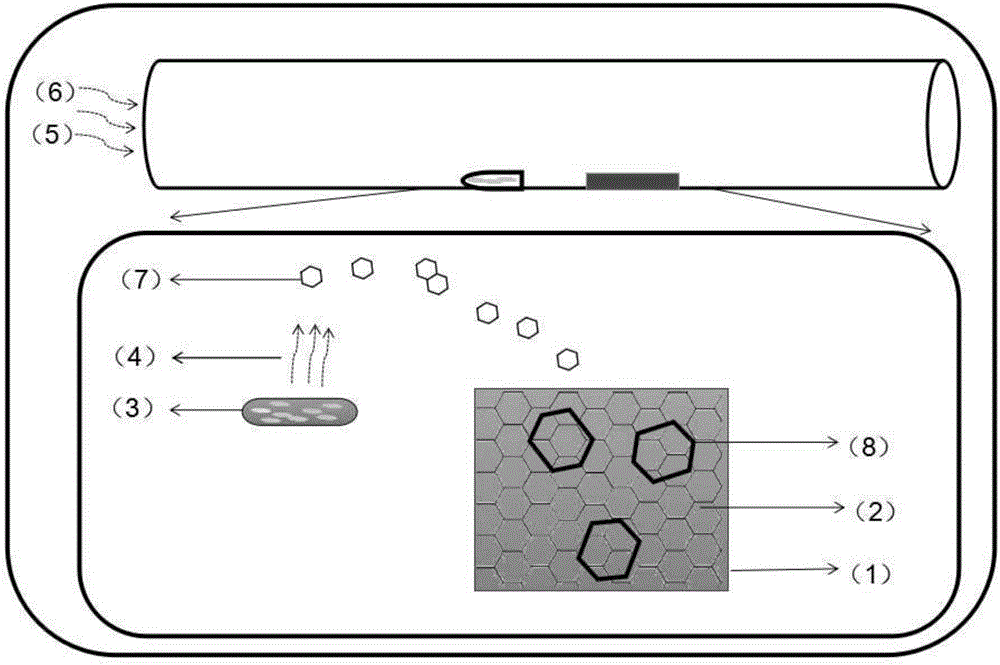

[0043] (2) Preparation of bilayer graphene by CVD system

[0044] Such as figure 1As shown, the nano-copper powder is packed in a ...

Embodiment 2

[0049] Embodiment 2, double-layer graphene grown on sapphire substrate

[0050] Follow the steps below to grow bilayer graphene on a sapphire substrate:

[0051] (1) Preparation of single-layer graphene and transfer

[0052] Using chemical vapor deposition equipment, based on the optimized growth conditions on the copper substrate, first obtain high-quality single-layer graphene, the transfer method is the same as in Example 1, except that the sapphire substrate is used when the film is finally picked up, that is, the transfer on the sapphire is obtained. Single-layer graphene films on substrates.

[0053] (2) Preparation of bilayer graphene by CVD system

[0054] This step is identical with embodiment 1, and difference is: insulating substrate is sapphire substrate; The spacing between small quartz tube and sapphire substrate is 5cm; When growing double-layer graphene, the rate that feeds methane is 20sccm, The rate of introducing hydrogen gas is 100 sccm; the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com