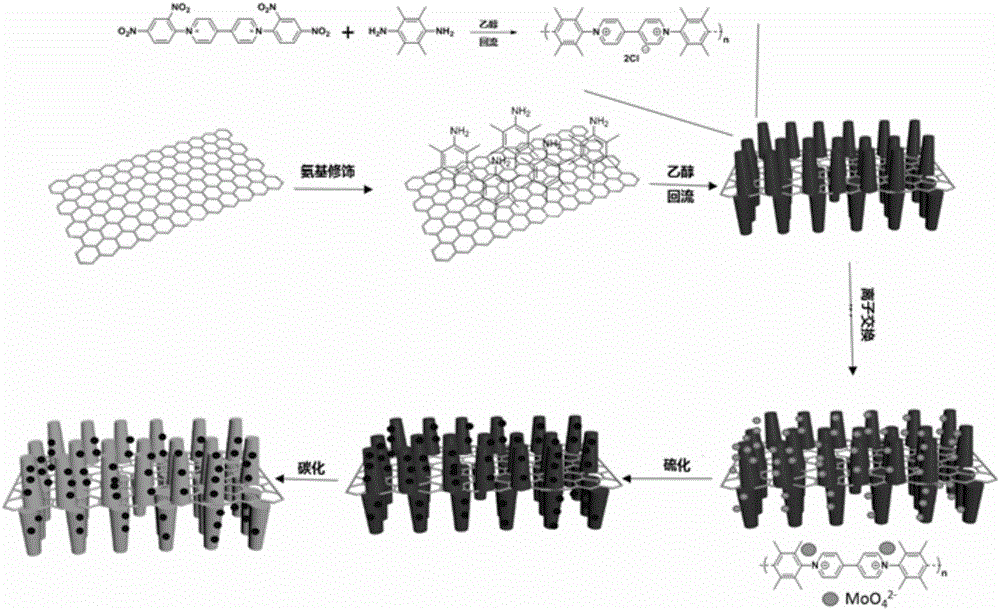

Molybdenum disulfide doped linear polymer modified graphene composite material and preparation method thereof

A linear polymer and composite material technology, applied in the direction of hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems of expensive platinum and limited application, and achieve uniform dispersion, excellent electrochemical performance, and small particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of graphene: Using 325 mesh graphite powder as raw material, graphene oxide was prepared by the improved hummer method, and the obtained graphite oxide was characterized by XRD, XPS, AFM and other methods.

[0032] (2) Preparation of 2,4-dinitrochlorobenzene: Get 50g of p-nitrochlorobenzene and pour it into a 2L round-bottomed flask, and add 120ml of fuming nitric acid dropwise to the flask under magnetic stirring to make all of the p-nitrochlorobenzene Dissolve, and then add 20ml of concentrated sulfuric acid dropwise to react for half an hour. After the system is cooled to room temperature, add ice water to quench the reaction to obtain a yellow solid, then wash with 500ml of deionized water, filter and vacuum dry to obtain 2,4-dinitrochloride benzene.

[0033] (3) Preparation of BDB: Put 50ml of acetonitrile into a 250ml round bottom flask, then add 2g of 4,4'-bipyridine and 10mg of 2,4-dinitrochlorobenzene into the flask, stir well to obtain a yellow...

Embodiment 2

[0040] (1) Preparation of graphene: Using 325 mesh graphite powder as raw material, graphene oxide was prepared by the improved hummer method, and the obtained graphite oxide was characterized by XRD, XPS, AFM and other methods.

[0041] (2) Preparation of 2,4-dinitrochlorobenzene: Get 50g of p-nitrochlorobenzene and pour it into a 2L round-bottomed flask, and add 150ml of fuming nitric acid dropwise to the flask under magnetic stirring to make all of the p-nitrochlorobenzene Dissolve, and then add 20ml of concentrated sulfuric acid dropwise to react for half an hour. After the system is cooled to room temperature, add ice water to quench the reaction to obtain a yellow solid, then wash with 500ml of deionized water, filter and vacuum dry to obtain 2,4-dinitrochloride benzene.

[0042] (3) Preparation of BDB: Put 50ml of acetonitrile into a 250ml round bottom flask, then add 2g of 4,4'-bipyridine and 10mg of 2,4-dinitrochlorobenzene into the flask, stir well to obtain a yellow...

Embodiment 3

[0049] (1) Preparation of graphene: Using 325 mesh graphite powder as raw material, graphene oxide was prepared by the improved hummer method, and the obtained graphite oxide was characterized by XRD, XPS, AFM and other methods.

[0050] (2) Preparation of 2,4-dinitrochlorobenzene: Get 50g of p-nitrochlorobenzene and pour it into a 2L round-bottomed flask, and add 120ml of fuming nitric acid dropwise to the flask under magnetic stirring to make all of the p-nitrochlorobenzene Dissolve, and then add 20ml of concentrated sulfuric acid dropwise to react for half an hour. After the system is cooled to room temperature, add ice water to quench the reaction to obtain a yellow solid, then wash with 500ml of deionized water, filter and vacuum dry to obtain 2,4-dinitrochloride benzene.

[0051] (3) Preparation of BDB: Put 50ml of acetonitrile into a 250ml round bottom flask, then add 2g of 4,4'-bipyridine and 10mg of 2,4-dinitrochlorobenzene into the flask, stir well to obtain a yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

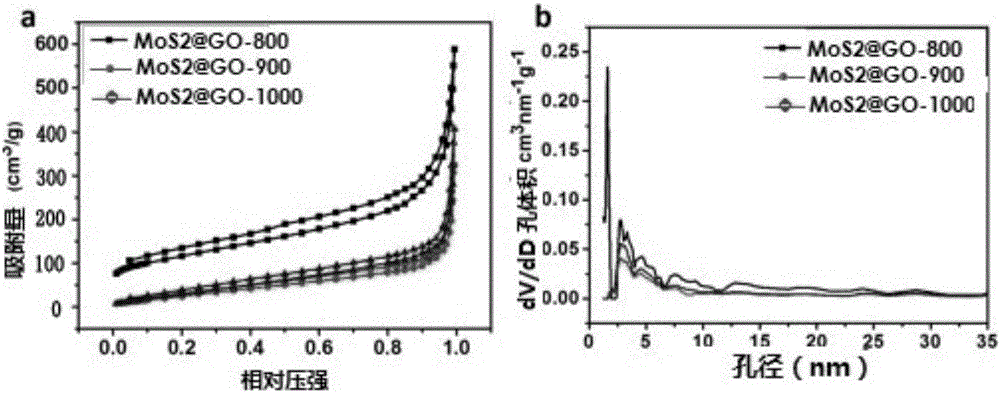

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com