Non-aqueous electrolyte and lithium-ion battery

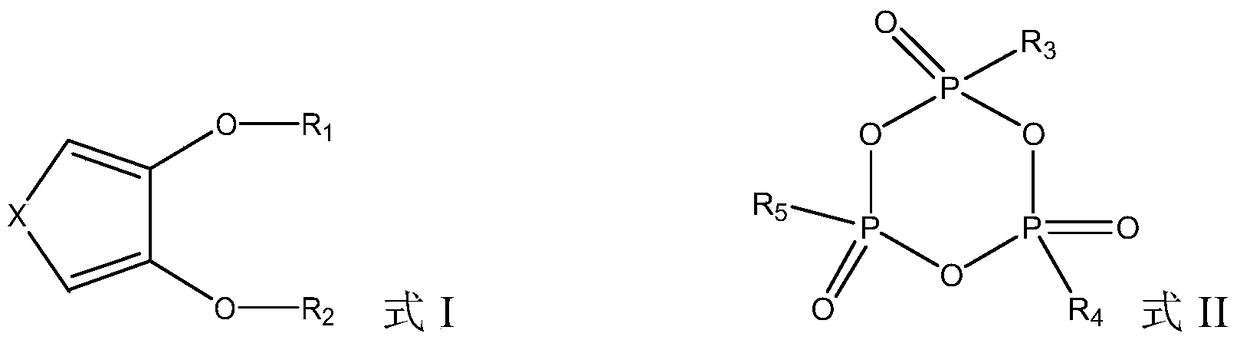

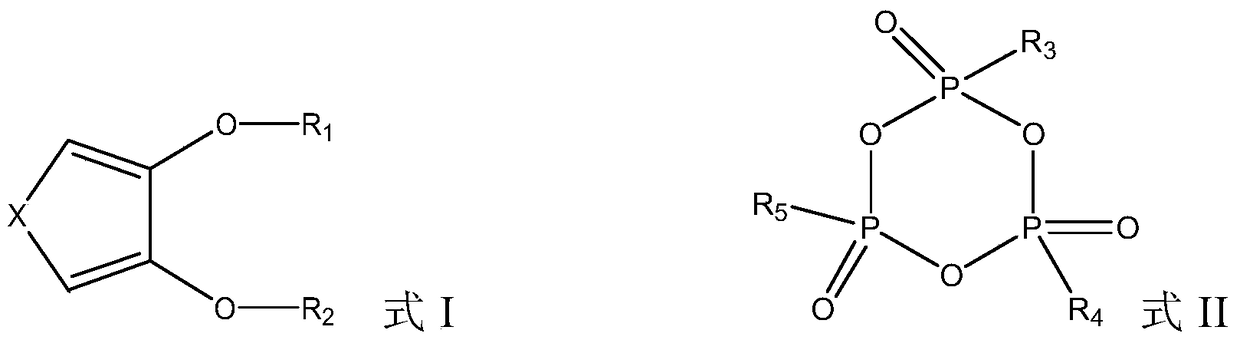

A non-aqueous electrolyte, non-aqueous technology, applied in non-aqueous electrolytes, secondary batteries, organic electrolytes, etc., can solve the problems affecting the storage performance and cycle performance of lithium-ion batteries, passivation film thickness, molecular chain breakage, etc. Achieve the effect of improving rate charging performance, preventing continuous reaction, and inhibiting oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of non-aqueous electrolyte: In a glove box or a drying room, ethylene carbonate (EC) and ethyl methyl carbonate (EMC) that have been rectified, dehydrated and purified are used as a non-aqueous organic electrolyte in a volume ratio of 3:7. The solvent is mixed, and then the lithium salt LiPF is added 6 , then add the 2-methyl-2,3-dihydrothieno[3,4-b][1,4]dioxane (formula III ) and the weight percentage in the non-aqueous electrolytic solution is 1% tripropyl phosphoric acid cyclic anhydride as an additive to complete the preparation of the non-aqueous electrolytic solution.

[0035]

[0036] (2) Preparation of lithium-ion battery: The positive electrode sheet prepared by lithium cobalt oxide as the positive electrode active material, the negative electrode sheet prepared by graphite as the negative electrode active material, and the polypropylene separator are wound, outsourced with aluminum-plastic film, and injected into the above-mentioned non-aque...

Embodiment 2

[0038] Lithium-ion battery is prepared according to the same method as in Example 1, except that adding in the non-aqueous electrolytic solution is 1% 3,4-ethylenedioxythiophene (formula IV) and in the non-aqueous electrolytic solution The non-aqueous electrolytic solution contains 1% by weight tripropylphosphoric acid cyclic anhydride as an additive.

[0039]

Embodiment 3

[0041] Lithium-ion batteries were prepared in the same manner as in Example 1, except that the electrolyte solution added 2-methyl-2,3-dihydrofuro[3 with a weight percentage of 1% in the nonaqueous electrolyte solution , 4-b] [1,4] dioxane (formula V) and tripropylphosphoric acid cyclic anhydride in the non-aqueous electrolyte with a weight percentage of 1% as additives.

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com