Preparation method of silver/graphene composite films and application of preparation method in ultraviolet detectors

A technology of ultraviolet detector and composite film, which is applied in the direction of using electric radiation detectors for photometry, ultraviolet measurement, and devices for coating liquid on the surface, etc. Improved agglomeration, enabling large-scale batch production, short response and recovery times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The sources of raw materials in the examples are: graphene oxide (>99wt%) and hydrazine hydrate (>98wt%) were purchased from Nanjing Pioneer Technology Company, and silver nitrate and sodium citrate powder were purchased from Aladdin Biochemical Technology Company.

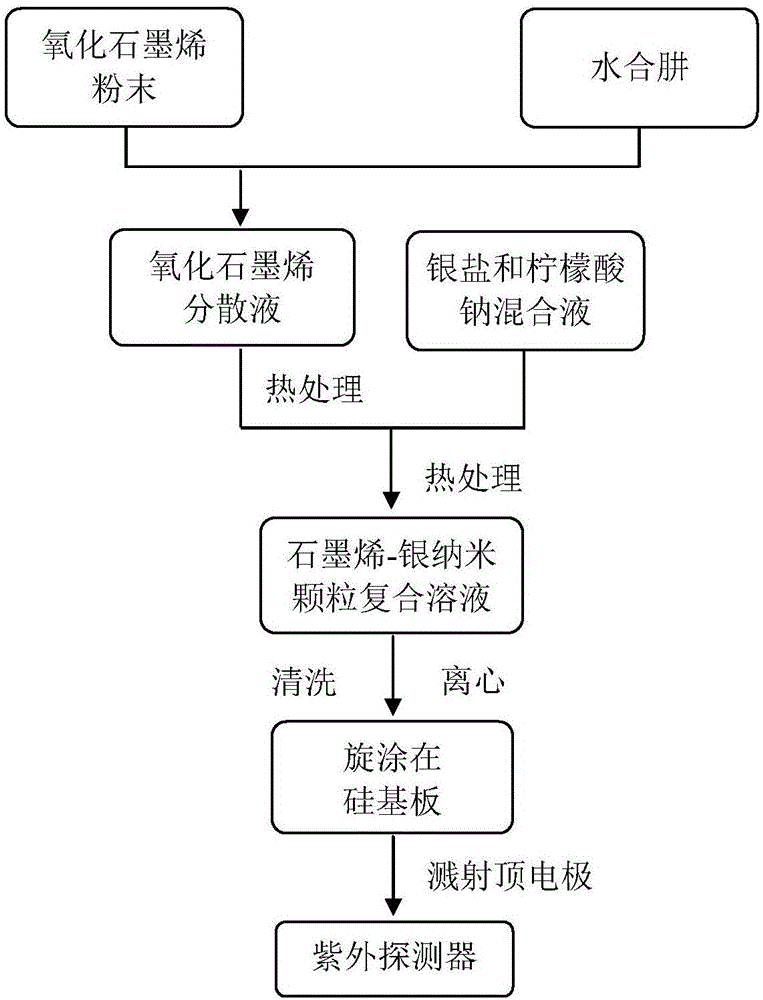

[0035] A preparation method of graphene-silver nanoparticle composite film, comprising the following steps:

[0036] Step 1: At room temperature, weigh 30mg of graphene oxide (>99wt%) and grind it into powder, mix it with 1mL of hydrazine hydrate (>98wt%), add 100mL of deionized water, and sonicate for 1h until there are no obvious particles to obtain uniform graphene oxide Dispersions;

[0037] Step 2: The graphene oxide dispersion obtained in step 1 was stirred and reacted in an oil bath at 100°C for 24 hours to complete the first in-situ reduction;

[0038] Step 3: At room temperature, weigh 45 mg of silver nitrate powder and 1 mg of sodium citrate, add 20 mL of deionized water, and ultrasonically mix u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com