Method for antibacterial lead-free low temperature frit and preparing method thereof

A low-temperature frit and melting technology, applied in the field of ceramics, can solve the problems of high toxicity, weakened antibacterial stability, loss of antibacterial effect, etc., and achieve the effect of lasting antifouling and self-cleaning, improving stability and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

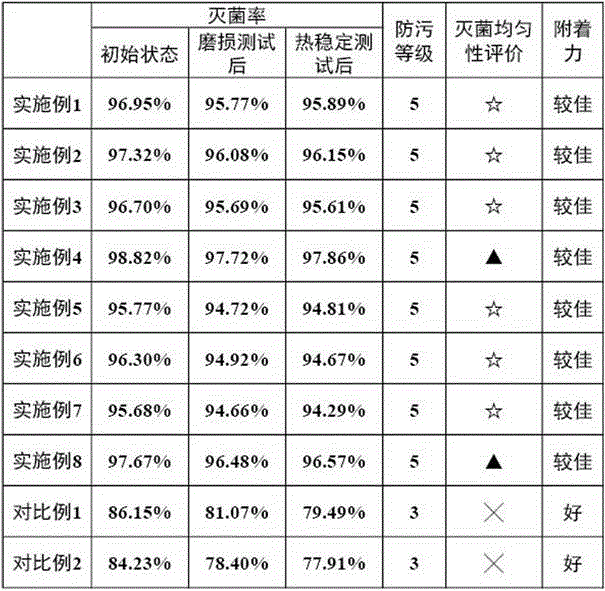

Examples

Embodiment 1

[0032] An antibacterial lead-free cadmium low-temperature frit and a preparation method thereof, the preparation method comprising the following steps:

[0033] A mixture: mix and grind 12% quartz, 12% feldspar, 25% borax, 6% carbonate, 35% boric acid, 5% spodumene, 4% fluoride salt, 0.9% kaolin, and then add 0.1 % antibacterial compound, grind uniformly and make mixture; Described feldspar is obtained by mixing potassium feldspar and albite feldspar by weight ratio 4:1; Described carbonate is obtained by potassium carbonate, sodium carbonate, barium carbonate, lithium carbonate and calcium carbonate in a weight ratio of 3:1:3:2:1; the fluoride salt is obtained by mixing sodium fluoride, calcium fluoride and lithium fluoride in a weight ratio of 4:2:1;

[0034] B Melting: Sprinkle the mixture prepared in step A into a refractory sagger, and perform high-temperature melting at 1250~1320°C to obtain a molten slurry; the high-temperature melting process is: room temperature is ra...

Embodiment 2

[0045] An antibacterial lead-free cadmium low-temperature frit and a preparation method thereof, the preparation method comprising the following steps:

[0046] A mixture: mix and grind 15% quartz, 9% feldspar, 23% borax, 10% carbonate, 28% boric acid, 6% spodumene, 3% fluoride salt, and 3% kaolin, and then add 3 % antibacterial compound, grind uniformly and make mixture; Described feldspar is obtained by mixing potassium feldspar and albite feldspar by weight ratio 4:1; Described carbonate is obtained by potassium carbonate, sodium carbonate, barium carbonate, lithium carbonate and calcium carbonate in a weight ratio of 3:1:3:2:1; the fluoride salt is obtained by mixing sodium fluoride, calcium fluoride and lithium fluoride in a weight ratio of 4:2:1;

[0047] B Melting: Sprinkle the mixture prepared in step A into a refractory sagger, and perform high-temperature melting at 1250~1320°C to obtain a molten slurry; the high-temperature melting process is: room temperature is ra...

Embodiment 3

[0058] An antibacterial lead-free cadmium low-temperature frit and a preparation method thereof, the preparation method comprising the following steps:

[0059] A mixture: mix and grind 18% quartz, 7% feldspar, 18% borax, 12% carbonate, 25% boric acid, 8% spodumene, 2% fluoride salt, 5% kaolin, and then add 5 % antibacterial compound, grind uniformly and make mixture; Described feldspar is obtained by mixing potassium feldspar and albite feldspar by weight ratio 4:1; Described carbonate is obtained by potassium carbonate, sodium carbonate, barium carbonate, lithium carbonate and calcium carbonate in a weight ratio of 3:1:3:2:1; the fluoride salt is obtained by mixing sodium fluoride, calcium fluoride and lithium fluoride in a weight ratio of 4:2:1;

[0060] B Melting: Sprinkle the mixture prepared in step A into a refractory sagger, and perform high-temperature melting at 1250~1320°C to obtain a molten slurry; the high-temperature melting process is: room temperature is raised...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com