Preparation method for antibacterial collagen

An antibacterial and collagen technology, which is applied in the field of preparation of antibacterial collagen, can solve problems such as difficult to achieve biological activity, inability to obtain antibacterial properties, difficult to dissolve, etc., and achieve good market prospects, not easy to lose, and long-lasting antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of antibacterial collagen, comprising the steps of:

[0033] (1) use 0.04mol / L barbiturate saline solution and 0.2mol / L hydrochloric acid aqueous solution preparation pH to be the buffer solution of 8.0;

[0034] Dissolving type I collagen extracted from bovine hide in a buffer solution, controlling the mass concentration of collagen to be 5%, to obtain a collagen solution;

[0035] (2) Add the modified triclosan with 1.5% collagen mass to the collagen solution in step (1), heat up to 35° C., and react for 24 hours to obtain an antibacterial collagen solution;

[0036] (3) The antibacterial collagen solution obtained in step (2) was dialyzed at 0-4° C. for 72 hours, and then freeze-dried to obtain the antibacterial collagen.

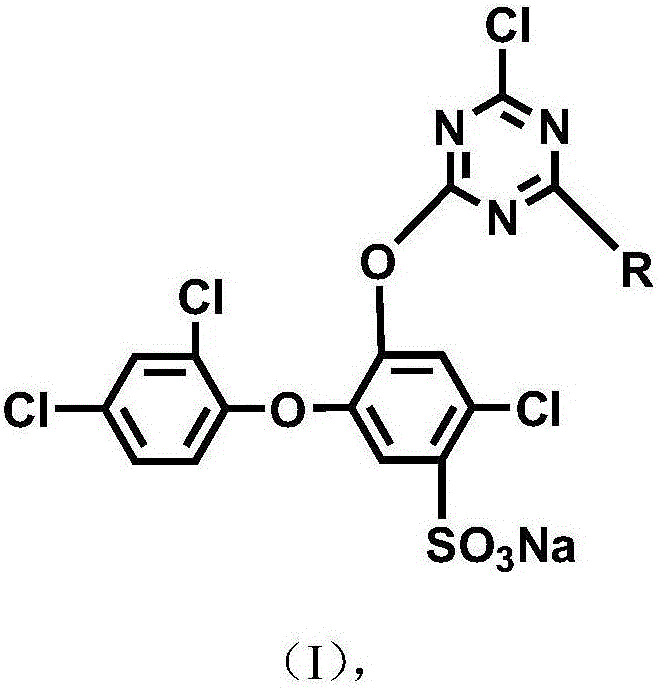

[0037] In the present embodiment, the modified triclosan has the following structure:

[0038]

[0039] The preparation process is as follows:

[0040] Dissolve triclosan in carbon tetrachloride solution, sulfonate with ...

Embodiment 2

[0042] A preparation method of antibacterial collagen, comprising the steps of:

[0043] (1) use the borax aqueous solution of 0.05mol / L and the boric acid aqueous solution preparation pH of 0.2mol / L to be the buffer solution of 7.8;

[0044] Dissolving the type I collagen extracted from the rat tail button in a buffer solution, controlling the mass concentration of the collagen to be 2.5%, to obtain a collagen solution;

[0045] (2) Add the modified triclosan with 5% collagen mass to the collagen solution obtained in step (1), heat up to 30° C., and react for 36 hours to obtain an antibacterial collagen solution;

[0046] (3) The antibacterial collagen solution obtained in step (2) was dialyzed at 0-4° C. for 48 hours, and then freeze-dried to obtain the antibacterial collagen.

[0047] In the present embodiment, the modified triclosan is a mixture with the following two structures:

[0048]

[0049] The preparation process is as follows:

[0050] Dissolve triclosan in ...

Embodiment 3

[0052] A preparation method of antibacterial collagen, comprising the steps of:

[0053] (1) Use 0.2mol / L glycine aqueous solution and 0.2mol / L sodium hydroxide aqueous solution to prepare a buffer solution with a pH of 9.2;

[0054] Dissolving the collagen I extracted from pigskin in a buffer solution, controlling the mass concentration of the collagen to be 2%, to obtain a collagen solution;

[0055] (2) Add the modified triclosan with 20% collagen quality to the collagen solution obtained in step (1), heat up to 37° C., and react for 24 hours to obtain an antibacterial collagen solution;

[0056] (3) The antibacterial collagen solution obtained in step (2) was dialyzed at 0-4° C. for 48 hours, and then freeze-dried to obtain the antibacterial collagen.

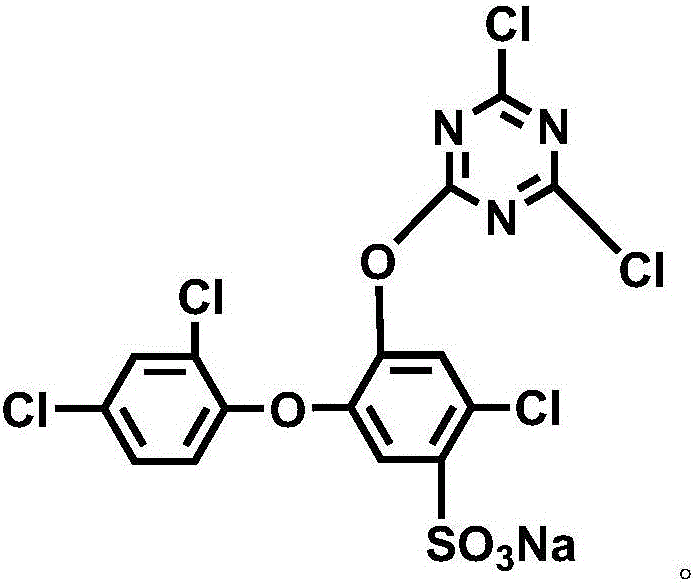

[0057] In the present embodiment, the modified triclosan has the following structure:

[0058]

[0059] The preparation process is as follows:

[0060] Dissolve triclosan in carbon tetrachloride solution, sulfonate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com