A preparation method for coating/ceramic inkjet printing with high-temperature and environment-friendly sub-nano zirconium silicate encapsulating cadmium-based pigments

A ceramic inkjet, environmentally friendly technology, used in inks, coatings, applications, etc., can solve problems such as poor performance, insufficient dispersibility, inapplicability, etc., to achieve strong color development, avoid particle enlargement, and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

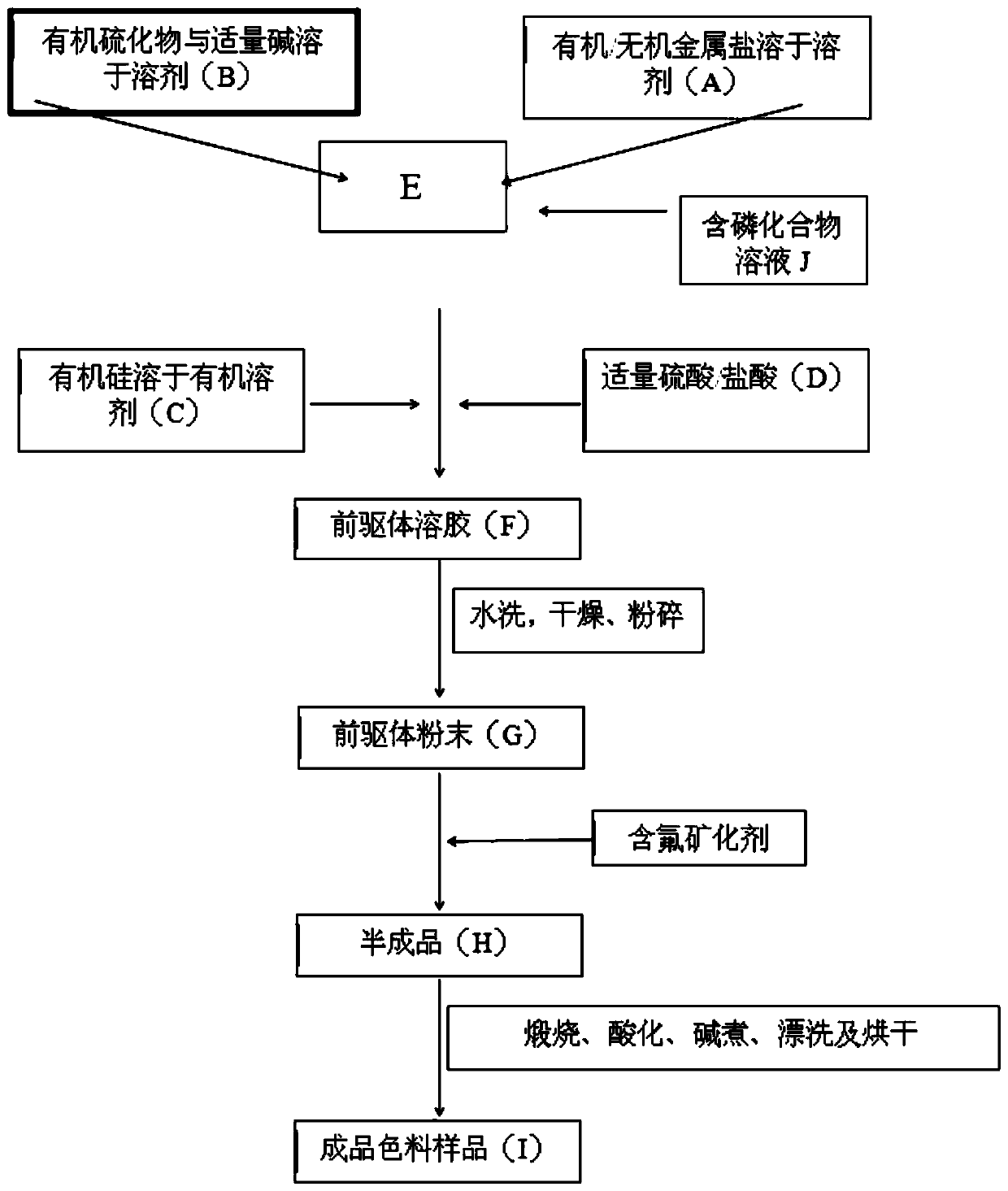

Method used

Image

Examples

Embodiment 1

[0041] The first step: 0.6mol of zirconium oxychloride, 0.06mol of cadmium chloride, 0.002mol of zinc chloride and 0.004mol of aluminum chloride are dissolved in propylene glycol to prepare a solution with a total mass fraction of 35%, which is denoted as A;

[0042] The second step: 0.14mol of sodium hydroxide, 0.06mol of ammonium sulfide, 0.01mol of selenium element and 0.001mol of tellurium element are dissolved in propylene glycol to prepare a solution with a total mass fraction of 11%, which is denoted as B;

[0043] The third step: take 0.6mol ethyl orthosilicate and dissolve it in propylene glycol, denoted as C;

[0044] The fourth step: dilute 30ml concentrated sulfuric acid into 500ml sulfuric acid solution (H 2 SO 4 , 98wt%), denoted as D;

[0045] Step 5: Dissolve 0.001mol of metaphosphoric acid in the solvent, denoted as J;

[0046] Step 6: Drop A and B in propylene glycol, keep stirring, and add J dropwise during the process, denoted as E;

[0047] Step 7: Aft...

Embodiment 2

[0054] The first step: 0.6mol of zirconium acetate, 0.06mol of cadmium acetate, 0.001mol of zinc acetate and 0.002mol of aluminum chloride are dissolved in propylene glycol to prepare a solution with a mass concentration of 35%, which is denoted as A;

[0055]Second step: 0.14mol of sodium hydroxide, 0.06mol of ammonium sulfide, 0.01mol of selenium element and 0.0008mol of tellurium element are dissolved in propylene glycol to prepare a solution with a mass concentration of 11%, which is denoted as B;

[0056] The third step: take 0.6mol ethyl orthosilicate and dissolve it in propylene glycol, denoted as C;

[0057] The fourth step: take 100mL concentrated hydrochloric acid and dilute it into 300ml hydrochloric acid solution (HCl, 37.5wt%), denoted as D;

[0058] Step 5: Dissolve 0.002mol of metaphosphoric acid in the solvent, denoted as J;

[0059] Step 6: Mix A and B co-dropwise, keep stirring, and add J dropwise during the process, denoted as E;

[0060] Step 7: After E i...

Embodiment 3

[0067] The first step: 0.8mol of zirconium acetate, 0.04mol of cadmium acetate, 0.005mol of zinc acetate and 0.004mol of aluminum chloride are dissolved in propylene glycol to prepare a solution with a mass concentration of 35%, which is denoted as A;

[0068] Second step: 0.12mol of sodium hydroxide, 0.04mol of ammonium sulfide, 0.008mol of selenium element and 0.002mol of hoof element are dissolved in propylene glycol to prepare a solution with a mass concentration of 11%, which is denoted as B;

[0069] The third step: take 0.9mol ethyl orthosilicate and dissolve it in propylene glycol, denoted as C;

[0070] The fourth step: take 100mL concentrated hydrochloric acid and dilute it into 300ml hydrochloric acid solution (HCl, 37.5wt%), denoted as D;

[0071] Step 5: Dissolve 0.006 mol of metaphosphoric acid in the solvent, denoted as J;

[0072] Step 6: Mix A and B co-dropwise, keep stirring, and add J dropwise during the process, denoted as E;

[0073] Step 7: After E is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com