Lubricant additive based on surface modified oxidized graphene, lubricant based on surface modified oxidized graphene, and preparation methods of lubricant additive and lubricant

A lubricating oil additive and surface modification technology, applied in the field of lubricating oil, can solve the problems of easy stratification and precipitation, and achieve the effect of high repetition rate, avoidance of addition and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

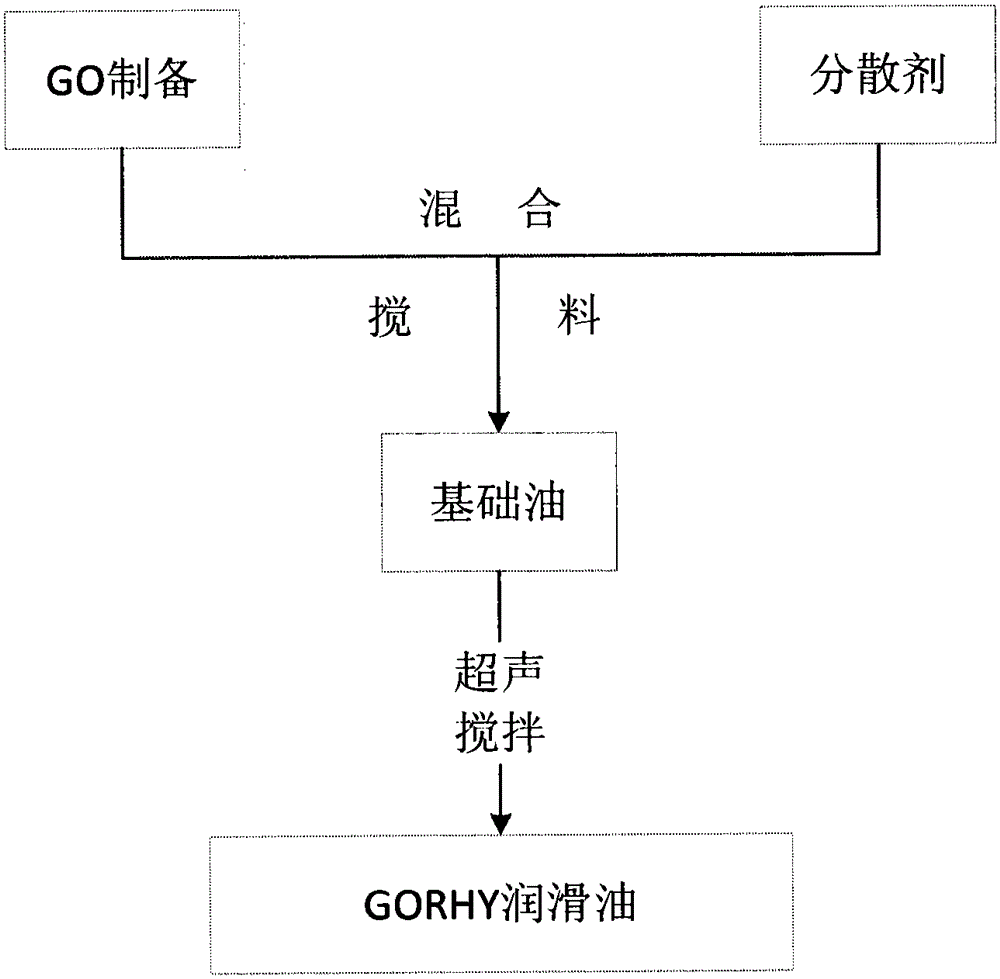

[0029] The invention also discloses a method for preparing a lubricating oil additive based on surface-modified graphene oxide, comprising the following steps:

[0030] Prepare graphite oxide and disperse it in an organic solvent to prepare a graphene oxide solution;

[0031] The aqueous solvent of bile salt or its derivatives is added to the prepared graphene oxide solution, and the reducing agent is added dropwise, and the target product is obtained after reaction.

[0032] or

[0033] Prepare graphene oxide and disperse it in water to prepare graphene oxide dilute solution;

[0034] The water solvent of bile salt or its derivatives is added to the prepared dilute graphene oxide solution, the temperature is raised to 60-80° C., and the target product is obtained after reaction.

[0035] Wherein, the organic solvent may be toluene, xylene, cyclohexane and the like.

[0036] Wherein, the obtained surface-modified graphene oxide has a thickness of 0.17-1.4 nm, and a sheet di...

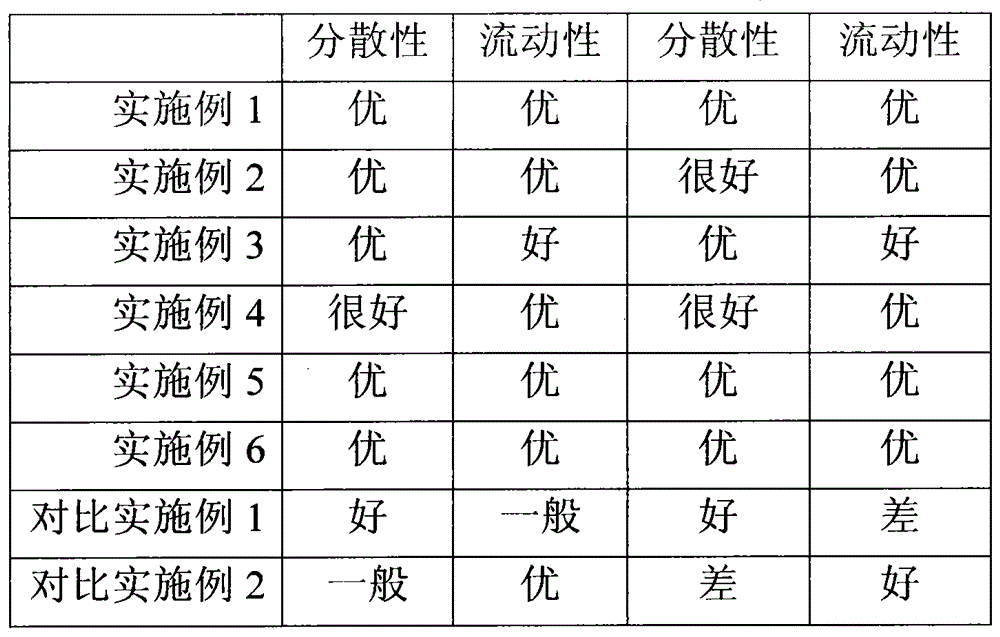

Embodiment 1

[0047]Preparation of graphite oxide: Using the Hummer method, add 2g flake graphite powder to a 250mL beaker, add 1g NaNO to it under the condition of ice water bath 3 After adding 46 mL of 98% H 2 SO 4 And stir well; slowly add 6g KMnO 4 , keep the temperature of the solution above 20°C and maintain this condition for 5 minutes, then remove the ice-water bath and heat to 35°C, and maintain this condition for 30 minutes; add 92mL of water and stir for another 15 minutes, the temperature will rise to about 98°C Continue to add 80 mL of 60°C 3% hydrogen peroxide, centrifuge the liquid after the above treatment for 30 minutes at 7200 rpm with a centrifuge; wash the residue with hot water until the pH of the upper suspension is about 7; disperse the obtained powder in Sonicate in water for 15 minutes, and obtain a uniform suspension after filtering the black residue; freeze-dry the suspension to obtain graphite oxide.

[0048] Preparation of graphene surface-treated with sodium...

Embodiment 2

[0051] The preparation method is the same as that in Example 1, except that 5.3 g of an aqueous solution of sodium deoxycholate with a concentration of 0.25 mol / L is added, the temperature is raised to 80° C., heated to reflux, and graphene oxide surface-treated with sodium deoxycholate is prepared by a two-phase method. , washed, filtered and dried to obtain a graphene oxide powder surface-treated with sodium deoxycholate.

[0052] 0.50% by mass percentage of sodium deoxycholate surface-treated graphene powder is added to the lubricating oil, stirred and mixed evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com