Dendrobium candidum health beverage and preparation method thereof

A technology for Dendrobium officinale and beverages, which can be applied to other dairy products, dairy products, milk preparations, etc., can solve the problems of affecting the taste and aroma of brewed tea, destroying the nutrition of tea leaves, etc., and achieve the effect of good maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

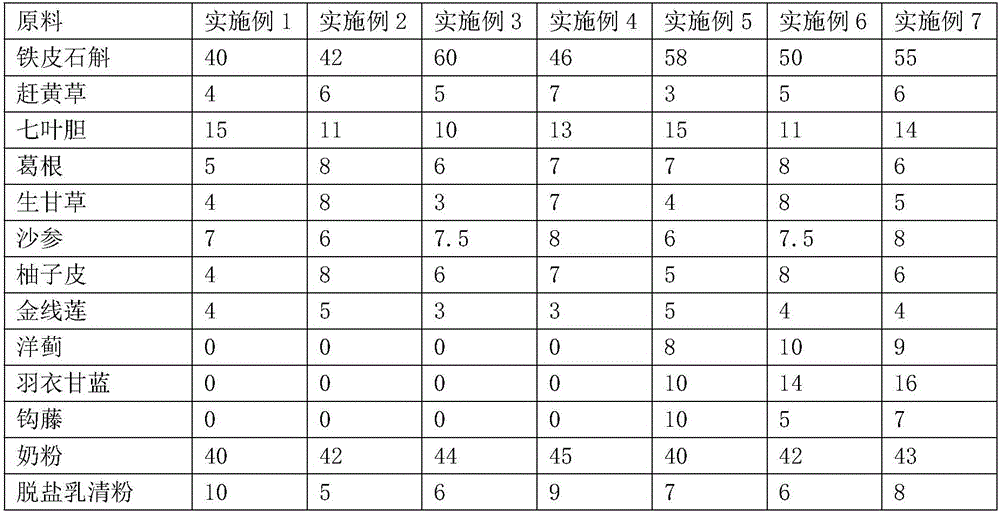

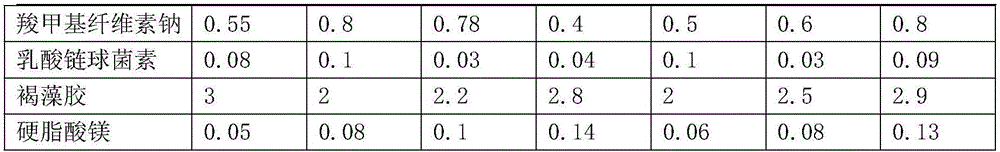

Embodiment 1~3

[0039] The preparation method of embodiment 1~3 is:

[0040] Take the raw material of component A, clean it, vacuum degree 20Pa, heat up for 3 hours, raise the temperature to 40°C and keep the temperature for 5 hours, then flatten the raw material of component A, crush it through a 100-mesh sieve for later use, and then put Put the pulverized raw material in a container, add 8 weight times of 95% ethanol, stir and mix evenly at a temperature of 30°C and a frequency of 35kHz for ultrasonic treatment for 20 minutes, reflux at room temperature, extract twice for 1 hour each time, and combine the extracts to obtain Filtrate and filter residue, the filtrate is concentrated to recover ethanol to obtain composite extract A, and the filter residue is dried for later use. Then add the milk powder of component B in the example to the composite extract A and dry mix it, and add it while stirring at 20°C to 30°C, and then add desalted whey powder, sodium carboxymethylcellulose, and nisin ...

Embodiment 4~5

[0041] The preparation method of embodiment 4~5 is:

[0042] Take the raw material of component A, clean it, vacuum degree 20Pa, heat up for 3 hours, raise the temperature to 50°C and keep the temperature for 5 hours, then flatten the raw material of component A, crush it through a 100-mesh sieve for later use, and then put Put the pulverized raw material in a container, add 10 times by weight of 95% ethanol, stir and mix evenly at a temperature of 40°C and a frequency of 40kHz for ultrasonic treatment for 15 minutes, reflux at room temperature, and extract once for 2 hours each time to obtain a filtrate and a filter residue. The filtrate was concentrated to recover ethanol to obtain compound extract A, and the filter residue was dried for later use. Then, the composite extract A is subjected to ultrafiltration membrane filtration, the filtered ultrafiltrate is added to the milk powder of component B in the example for dry mixing, and the desalted milk is added sequentially ac...

Embodiment 6~7

[0043] The preparation method of embodiment 6~7 is:

[0044] Take the raw material of component A, clean it, vacuum degree 20Pa, heat up for 3 hours, raise the temperature to 50°C and keep the temperature for 5 hours, then flatten the raw material of component A, crush it through a 100-mesh sieve for later use, and then put Put the pulverized raw material in a container, add 10 times by weight of 95% ethanol, stir and mix evenly at a temperature of 40°C and a frequency of 40kHz for ultrasonic treatment for 15 minutes, reflux at room temperature, and extract once for 2 hours each time to obtain a filtrate and a filter residue. The filtrate was concentrated to recover ethanol to obtain compound extract A, and the filter residue was dried for later use. Then, the composite extract A is subjected to ultrafiltration membrane filtration, the filtered ultrafiltrate is added to the milk powder of component B in the example for dry mixing, and the desalted milk is added sequentially ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com