Potato resistance increasing powder and potato steamed bun premixing powder with function of lowering blood sugar

A technology of potato and premixed powder, which is applied in application, food preparation, food science, etc. It can solve the problems of poor gas holding capacity of gluten network, small size of potato steamed buns, and rough surface of steamed buns, and achieves fast dissolution, simple composition, Difficult to digest and absorb in the small intestine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

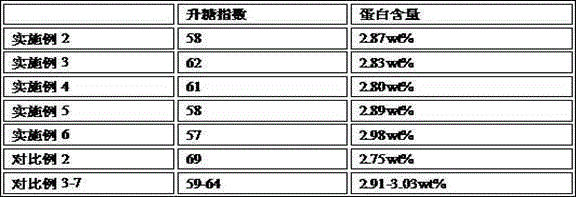

Examples

Embodiment 1

[0031] After the potatoes are broken, let them stand until they are separated into layers, pour off the upper liquid, wash the sediment with water until the supernatant is clear; mix the washed sediment with water at a ratio of 1:3-8g / mL to obtain potato pulp; Microwave the pulp under the condition of microwave power 400-600W for 50-200s, then place it in a water bath at 55°C for 18-24h, and then age it at 4°C for 12-36h; filter the aged potato pulp Dry at 40-45°C for 24 hours, then pulverize and pass through a 100-mesh sieve, and collect the under-sieve to become potato-enhancing powder. The resistant starch content in the potato enhanced powder was 24.86wt% (accounting for the proportion of the total starch dry basis).

Embodiment 2

[0035] Make steamed bread premix powder according to the following formula: 300g all-purpose flour, 400g potato powder, 100g potato α starch, 30g dendrobium powder, 30g guava leaf powder, 10g red peony powder, 15g mulberry powder, Astragalus powder 15g, edible gum 15g, steamed bread improver 10g, yeast 5g, baking powder 10g.

[0036] Mix the above components according to the proportion, stir evenly in the mixer, add 500mL of water, stir for 2 minutes in the dough mixer, then put the dough in a proofer at 38°C to ferment for 40 minutes, take out the dough and press it 10 times, shape it, and put it in Proof in the proofing box for 15 minutes, put it into the steamer and steam for 30 minutes. After turning off the fire for 2 minutes, uncover the pot cover, cover the steamed buns with gauze and cool at room temperature for 20 minutes, then analyze the relevant quality characteristics.

Embodiment 3

[0038] Make steamed bread premix powder according to the following formula: 300g all-purpose flour, 300g potato powder, 50g potato α starch, 30g dendrobium powder, 30g guava leaf powder, 10g red peony powder, 15g mulberry powder, Astragalus powder 15g, edible gum 15g, steamed bread improver 10g, yeast 5g, baking powder 10g.

[0039] Mix the above components according to the proportion, stir evenly in the mixer, add 500mL of water, stir for 2 minutes in the dough mixer, then put the dough in a proofer at 38°C to ferment for 40 minutes, take out the dough and press it 10 times, shape it, and put it in Proof in the proofing box for 15 minutes, put it into the steamer and steam for 30 minutes. After turning off the fire for 2 minutes, uncover the pot cover, cover the steamed buns with gauze and cool at room temperature for 20 minutes, then analyze the relevant quality characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com