Polyethylene resin, preparation method and applications thereof

A technology of polyethylene resin and ethylene, which is applied in the field of high chlorinated polyethylene, can solve the problems of adverse effects on the solubility of HCPE, uneven distribution of product particles, and increased raw material costs, and achieve narrow molecular weight distribution index, good chlorination performance, Excellent solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

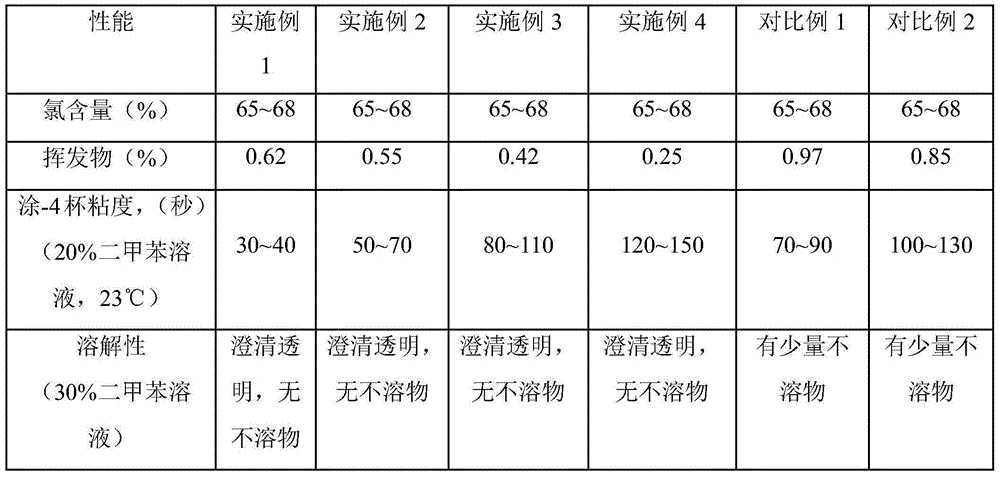

[0034] The preparation of HCPE in the examples is prepared by the aqueous phase suspension method. Specifically, 0.2 parts of dispersant (polyvinyl alcohol), 0.005 parts of suspension stabilizer (ethylene oxide propylene oxide copolymer), 0.005 parts of emulsifier (octylphenol poly Oxyethylene ether) 0.03 parts, add the PE resin powder (5-5.5 parts) for HCPE under the stirring condition, after fully stirring, heat to 35-45 ℃ through the hot water of the jacket, then add the initiator into the heated water Agent dibenzoyl peroxide (BPO) 0.02~0.03 parts, initiator dicumyl peroxide (DCP) 0.015~0.025 parts, continue heating to 60°C under sealed conditions, and pass through the water after the second temperature rise. Into chlorine, the total amount of chlorine is 22 parts by weight. The chlorination process is carried out in three stages. The first stage feeds 55% of the total amount of chlorine gas and reacts for 2.5 to 3 hours at a temperature of 75-88°C and a pressure of <0.2M...

Embodiment 1

[0039] According to the PE resin for HCPE of the present invention, prepare as follows: 1) add 200 liters of hexane solvents in 300 liters of reactors; Rinse through 1L hexane, add loaded metallocene catalyst and cocatalyst triethyl Aluminum (hexane solvent, the concentration is 0.88mol / L), start the stirring, the stirring speed is 250rpm, and at the same time heat the material in the reactor to 70-85°C through the external circulating water;

[0040] 2) Add 5 grams of hydrogen into the reactor at one time, continuously feed ethylene, and add 200 g of comonomer 1-butene in batches at the same time; adjust the feeding of ethylene to maintain the pressure in the reactor at 0.5-0.8 MPa for slurry polymerization 2 Hour, the total addition of ethylene in this process is 22kg.

[0041] 3) After the reaction is over, stop feeding ethylene, reduce the temperature of the material in the reactor to 25°C through external circulating water, vent the pressure in the reactor, release the po...

Embodiment 2

[0044] The difference from Example 1 is:

[0045] The solvent is changed into isobutane, and the hydrogen addition is 4 grams, and the comonomer butene-1 is changed into hexene-1, and the addition is changed into 75 grams;

[0046] The test results of this polyethylene resin are shown in Table 1; the properties of polyethylene resin chlorinated products are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com