A chemical synthesis method of inorganic non-lead halide perovskite thin film

A halide perovskite, chemical synthesis technology, applied in the direction of semiconductor devices, electrical components, photovoltaic power generation, etc., can solve the problems of Pb pollution, organic matter instability, etc., and achieve low equipment requirements, low cost, and solve unstable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

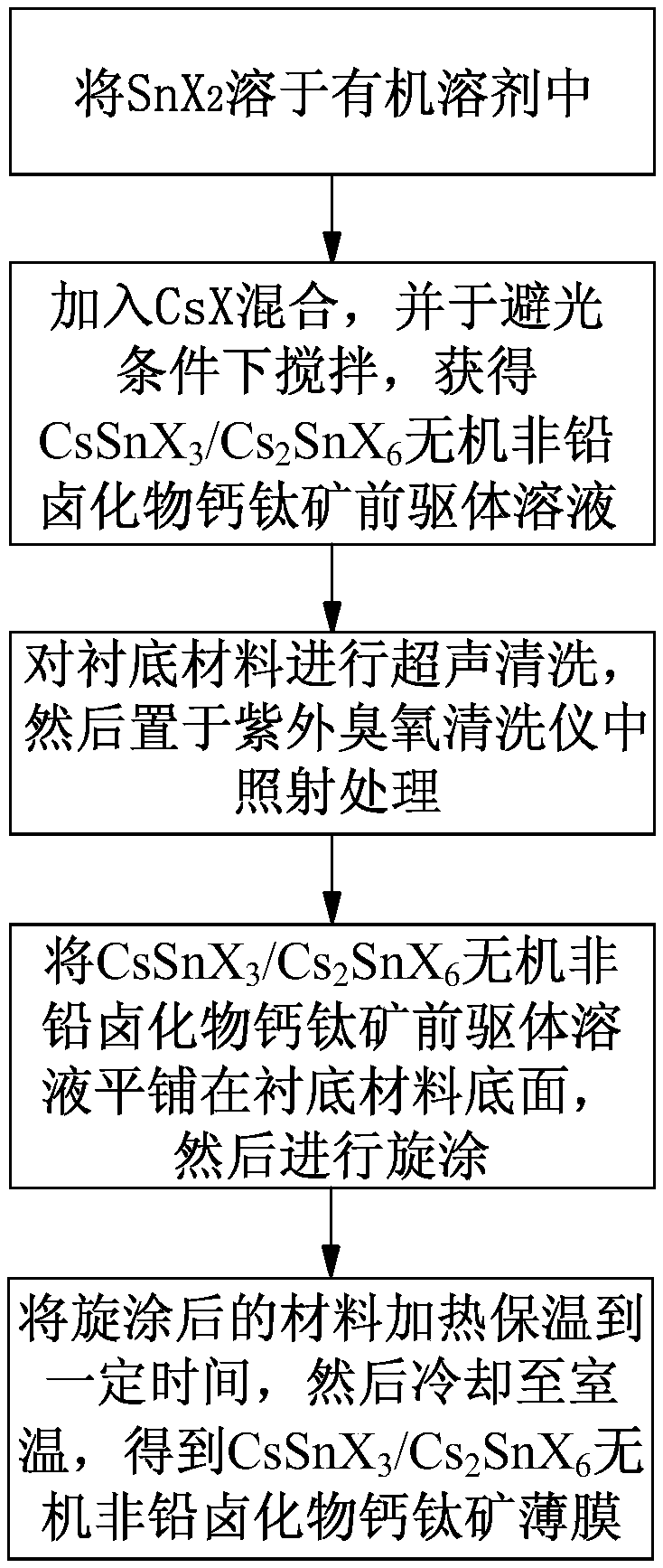

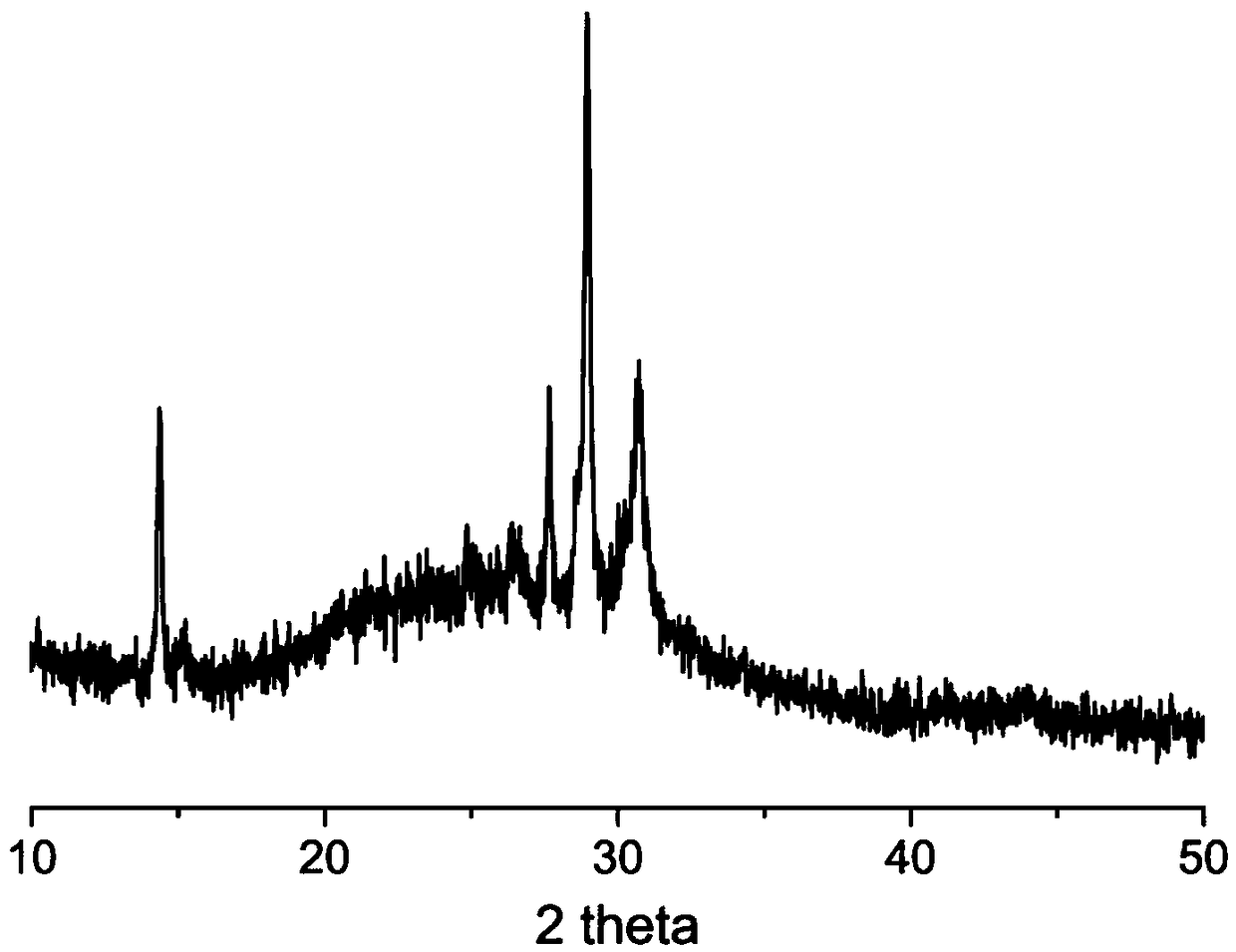

[0029] The invention provides a kind of inorganic non-lead halide (chemical formula is CsSnX 3 or Cs 2 wxya 6 , X is one or more of the halogen elements Cl, Br or I) perovskite thin films, which are mainly used in perovskite batteries. like figure 1 As shown, the process of preparing this kind of inorganic non-lead halide perovskite film is as follows:

[0030] 1. CsSnX 3 / Cs 2 wxya 6 Synthesis of Inorganic Non-Lead Halide Perovskite Precursor Solutions

[0031] (1) SnX 2 Dissolve in an organic solvent, and magnetically stir until completely dissolved, with a solubility of 0.1-5mol / L; the organic solvent is preferably DMF, DMSO, ether or isopropanol;

[0032] (2) Add CsX to mix (CsX and SnX 2 The molar mass ratio is 1-2:1), and stirred at 50-100°C and protected from light for 2-24 hours to obtain CsSnX 3 / Cs 2 wxya 6 Inorganic non-lead halide perovskite precursor solution;

[0033] The above-mentioned CsSnX 3 / Cs 2 wxya 6 The synthesis process of the inorganic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com