Batch synthesis method for green fluorescent nano carbon clusters

A green fluorescence, carbon nanocluster technology, applied in the multi-intersection research field, can solve the problems of low fluorescence quantum yield, no carbon cluster research papers and patent publications, etc., to achieve broad application prospects, easy to scale batches Simple effect of production, separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

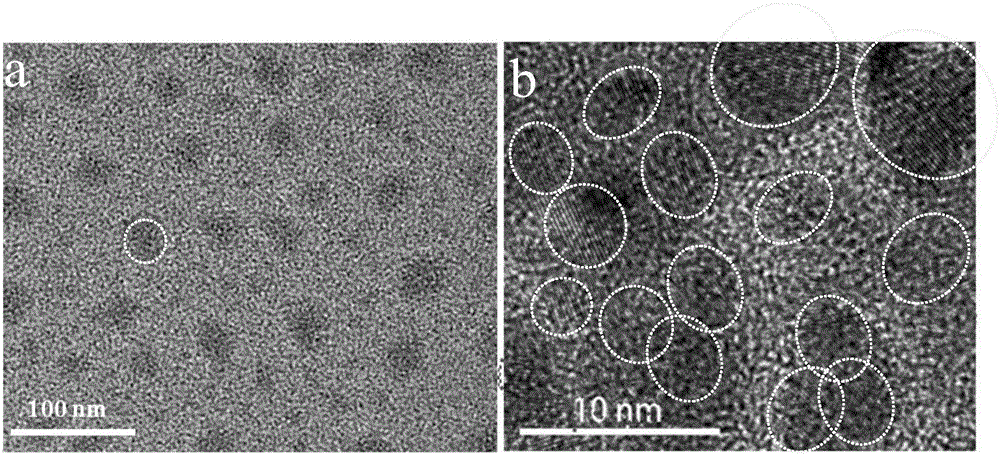

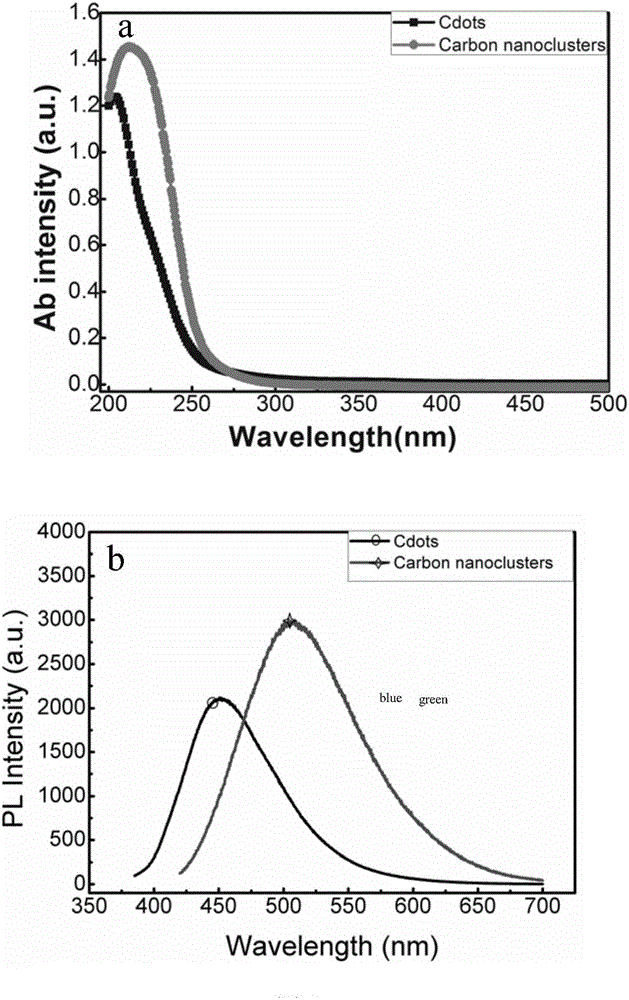

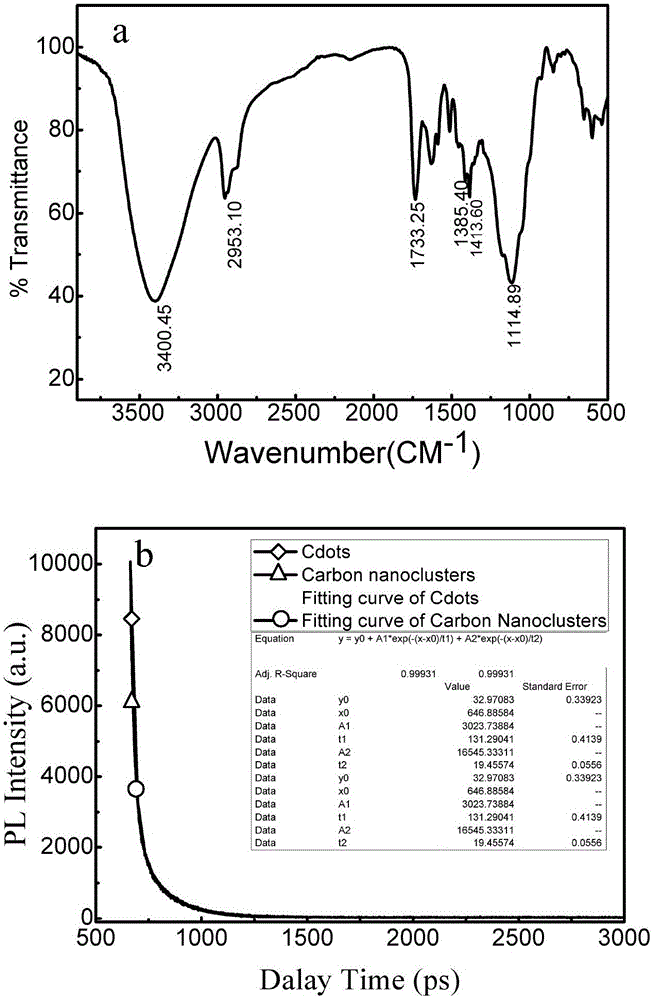

Image

Examples

Embodiment 1

[0040] This embodiment relates to a new method for preparing carbon nanoclusters, the method comprising the following steps:

[0041] Using glucose as the carbon precursor and leucine as the auxiliary reagent, the fluorescent carbon nanoclusters were prepared by reacting in an ethylene glycol medium, specifically:

[0042] (1) At room temperature, weigh 0.5g glucose and 0.5g leucine, dissolve them in a 25mL ethylene glycol round-bottomed flask under magnetic stirring, add concentrated phosphoric acid to the mixture, and make a mass ratio of 15 % ethylene glycol phosphoric acid solution, after the reactants are completely dissolved, heat to reflux for reaction, keep the temperature at 140°C and keep the reaction for 60 minutes, the concentration of the reaction solution turns from colorless and transparent to a dark brown solution, stop the reaction, cool and purify and separate.

[0043] (2) centrifuge the mixed solution obtained in step (1) at 5000r / min, and discard the preci...

Embodiment 2

[0048] Using citric acid as a carbon precursor and glutathione as an auxiliary reagent, the fluorescent carbon nanoclusters were prepared by reacting in an ethylene glycol medium, specifically:

[0049] (1) At room temperature, weigh 1g of citric acid and 0.5g of glutathione, dissolve them in a 25mL ethylene glycol round-bottomed flask under magnetic stirring, add concentrated phosphoric acid to the mixture, and make a mass ratio 5% phosphoric acid ethylene glycol solution, after the reactants are completely dissolved, heat to reflux for reaction, keep the temperature at 160°C and keep the reaction for 80 minutes, the concentration of the reaction solution turns from colorless and transparent to a dark brown solution, stop the reaction, cool and purify and separate.

[0050] (2) centrifuge the mixed solution obtained in step (1) at 8000r / min, and discard the precipitate.

[0051] (3) Put the supernatant in step (2) into a dialysis bag with a molecular weight cut-off of 500, pl...

Embodiment 3

[0055] Using citric acid as a carbon precursor and horseradish peroxygenase as an auxiliary reagent, react fluorescent carbon nanoclusters in a glycerol medium, specifically:

[0056] (1) At room temperature, weigh 1g of citric acid and 0.25g of horseradish peroxygenase, dissolve them in a 25mL ethylene glycol round-bottomed flask under magnetic stirring, and add concentrated phosphoric acid to the mixture to prepare the mass Compared with 20% phosphoric acid ethylene glycol solution, after the reactant is completely dissolved, heat to reflux for reaction, keep the temperature at 180°C and keep the reaction for 120min, the concentration of the reaction solution turns from colorless and transparent to a dark brown solution, stop the reaction, cool and purify and separate .

[0057] (2) centrifuge the mixed solution obtained in step (1) at 7000r / min, and discard the precipitate.

[0058] (3) The supernatant in step (2) is placed in a large amount of ultrapure water in a dialysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com