Green phosphor and preparation method thereof

A technology of green fluorescent powder and fluorescent powder, which is applied in the field of materials science, can solve the problems of green fluorescent powder luminous efficiency, luminance not meeting practical requirements, low quantum efficiency of fluorescent powder, high preparation temperature requirements, etc., achieving remarkable technological progress , high quantum efficiency and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of green phosphor Sr 9-x Mg 1.5 (PO 4 ) 7 : xTb 3+ (x=0.01) preparation method, comprises the steps:

[0017] a. Weigh 3.2032 g of strontium carbonate, 0.3446 g of basic magnesium carbonate, 0.0064 g of terbium oxide, and 0.5602 g of ammonium dihydrogen phosphate, and place them in a mortar;

[0018] b. Grind the mixture obtained in a for 50 minutes, then add alcohol and grind it for 60 minutes;

[0019] c. Put the mixture obtained in b into a crucible boat, place the crucible in a double-temperature zone tube furnace, and calcinate at 1300°C for 9 hours under a CO reducing atmosphere, then cool naturally and grind it into powder to obtain single-matrix phosphate green light phosphor.

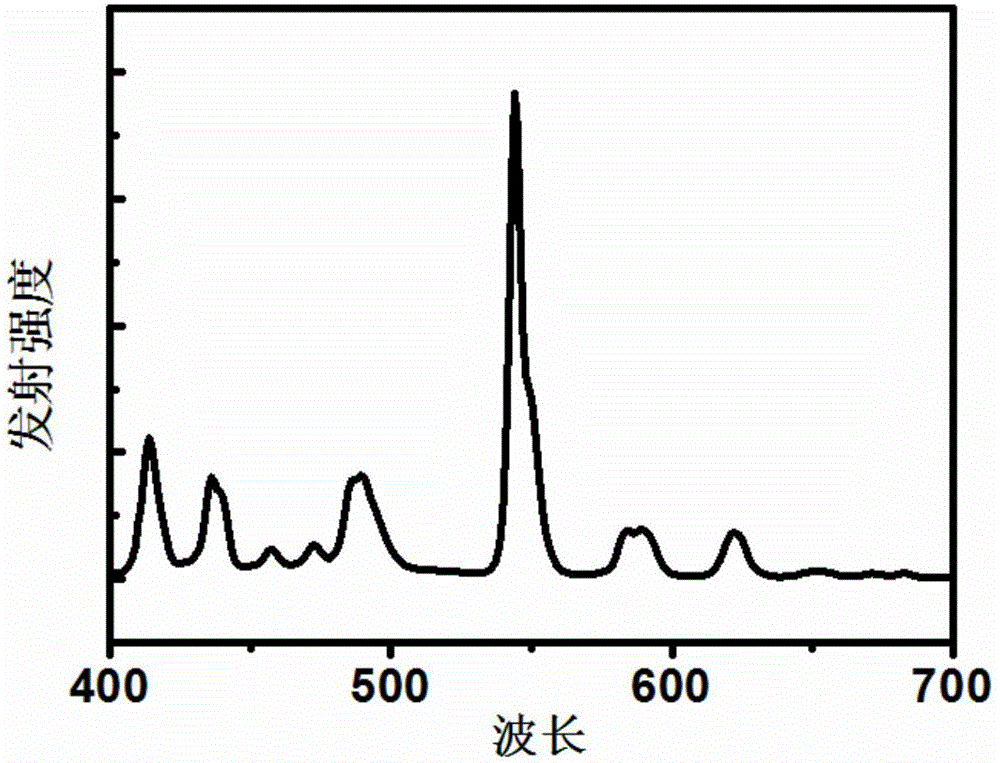

[0020] Sr 9-x Mg 1.5 (PO 4 ) 7 : xTb 3+ (x=0.01) Under the excitation of 230nm ultraviolet light, the main emission peak of the emission spectrum is located at 544nm, and the green light emission is strong and pure. attached image 3 Sr in this example 9-x Mg 1.5 (P...

Embodiment 2

[0022] A kind of green phosphor Sr 9-x Mg 1.5 (PO 4 ) 7 : xTb 3+ (x=0.05) preparation method, comprises the steps:

[0023] a. Weigh 3.1766 g of strontium carbonate, 0.3558 g of basic magnesium carbonate, 0.1329 g of terbium nitrate, and 0.5790 g of ammonium dihydrogen phosphate, and place them in a mortar;

[0024] b. Grind the mixture obtained in a for 120min, then add alcohol and grind for 50min;

[0025] d. Put the mixture obtained in b into a crucible boat and place it in a tube furnace with dual temperature zones. After calcining at 1200°C for 8 hours under a CO reducing atmosphere, cool naturally and grind it into powder to obtain a single-matrix phosphate that emits green light. Phosphor.

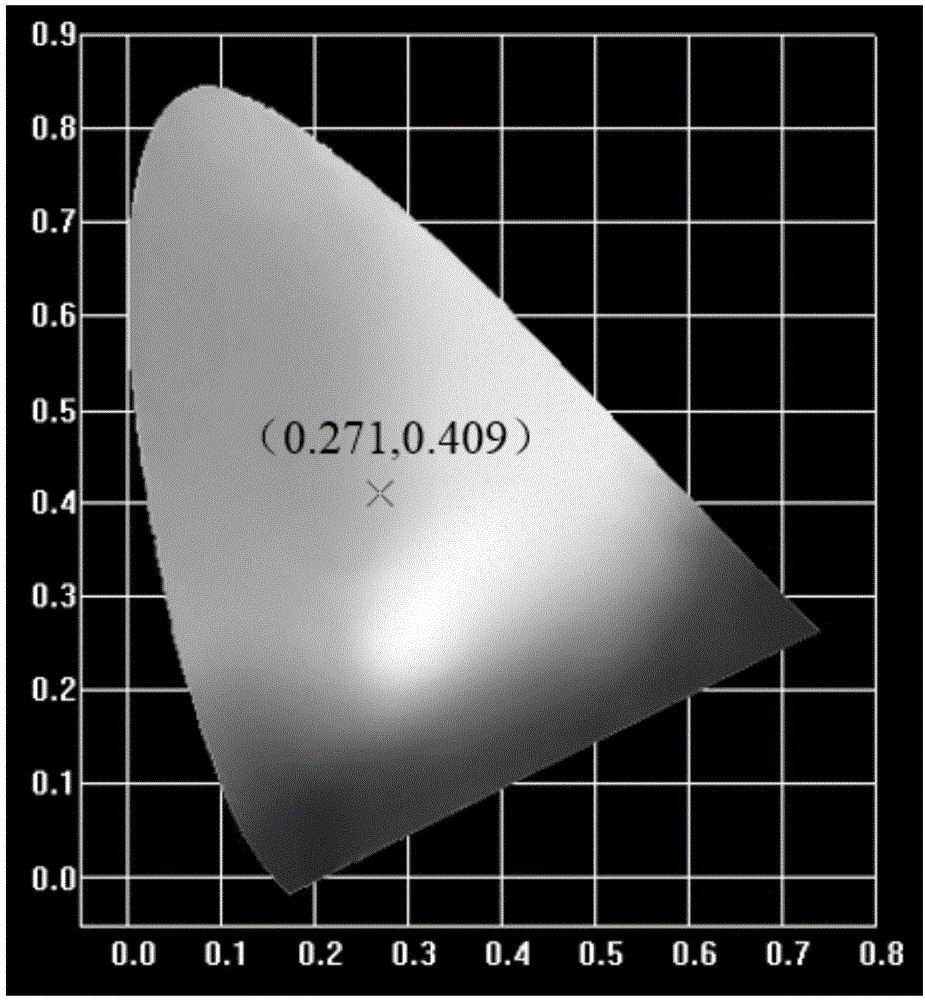

[0026] Sr 9-x Mg 1.5 (PO 4 ) 7 : xTb 3+ (x=0.05) Under the excitation of 230nm ultraviolet light, the main emission peak of the emission spectrum is located at 544nm, and the green light emission is strong and pure. The chromaticity coordinates of the prepared green phosp...

Embodiment 3

[0028] A kind of green phosphor Sr 9-x Mg 1.5 (PO 4 ) 7 : xTb 3+ (x=0.1) preparation method, comprises the steps:

[0029] a. Weigh 3.1407 g of strontium carbonate, 0.3708 g of basic magnesium carbonate, 0.0693 g of terbium oxide, and 0.6042 g of ammonium dihydrogen phosphate, and place them in a mortar;

[0030] b. Grind the mixture obtained in a for 70 min, then add acetone and grind for 50 min;

[0031] c. Put the mixture obtained in b into a crucible boat and place it in a tube furnace with two temperature zones, calcinate at 1100° C. for 10 hours under a CO reducing atmosphere, cool naturally and grind into powder.

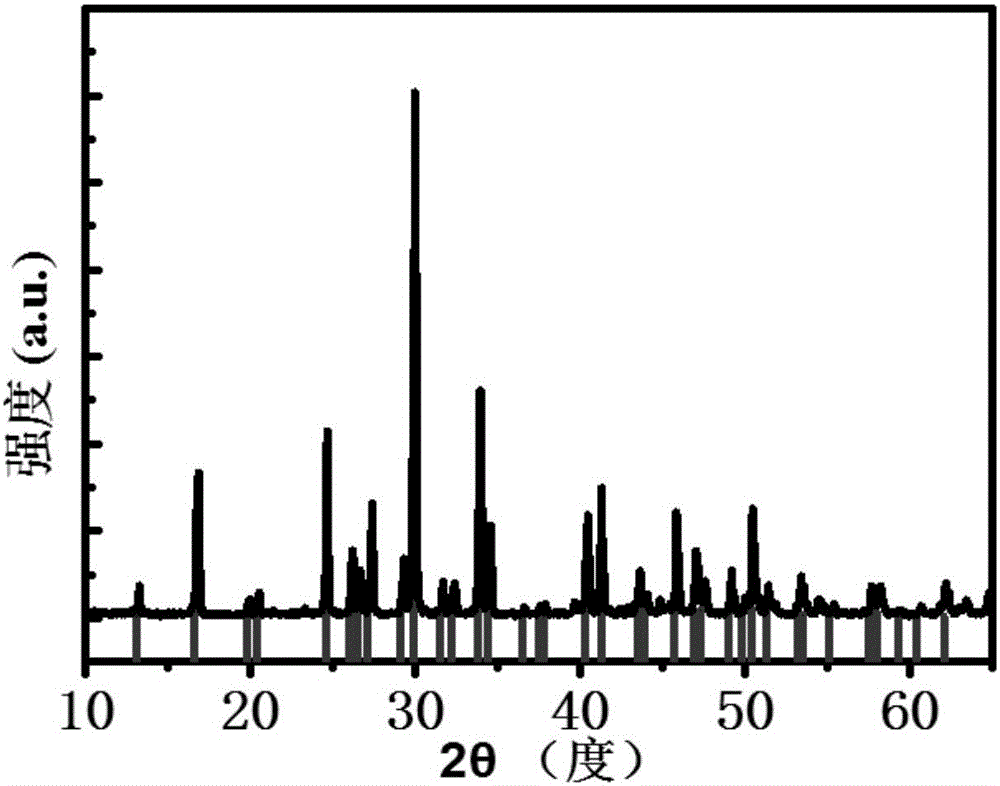

[0032] attached figure 1 Be the X-ray diffraction pattern of this embodiment, all emission lines are all with Sr 9 Mg 1.5 (PO 4 ) 7 The standard peak positions are the same. The resulting crystal is a single Sr 9 Mg 1.5 (PO 4 ) 7 : Tb 3+ Trigonal, Tb 3+ In the crystal instead of Sr 3+ position, its structure does not change and does not cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com