Preparation method of denitration and demercuration integrated catalyst powder

A catalyst and mercury removal technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as cracking and uneven dispersion of active substances, and achieve simple operation process, stable product quality, and environmental impact. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

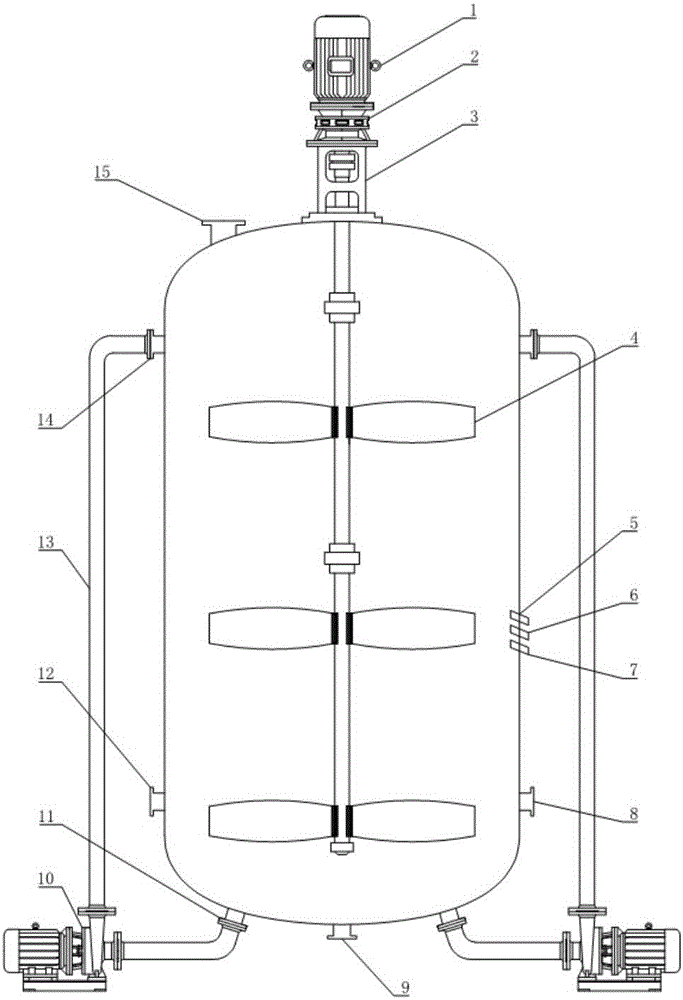

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The specific implementation steps of a preparation method of a denitrification and demercury integrated catalyst powder are as follows:

[0029] 1) The TiO obtained in the process of preparing titanium dioxide by sulfuric acid 2 ·H 2 O (hydrated titanium dioxide, also known as metatitanic acid) filter cake and water are mixed and beaten in a stirring tank to make TiO 2 ·H 2 Titanium solution of O;

[0030]2) Add NH to the mixing tank 3 ·H 2 O, the pH of the slurry, NH 3 ·H 2 O and TiO 2 ·H 2 SO entrained in O filter cake 4 2- Ion reaction formation (NH 4 ) 2 SO 4 , so that the slurry has a certain viscosity; then add a suspending agent to the slurry to enhance the dispersion and stability of the slurry; add a certain amount of nano-CeO to the titanium solution 2 powder;

[0031] 3) Start the stirrer positioned at the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com