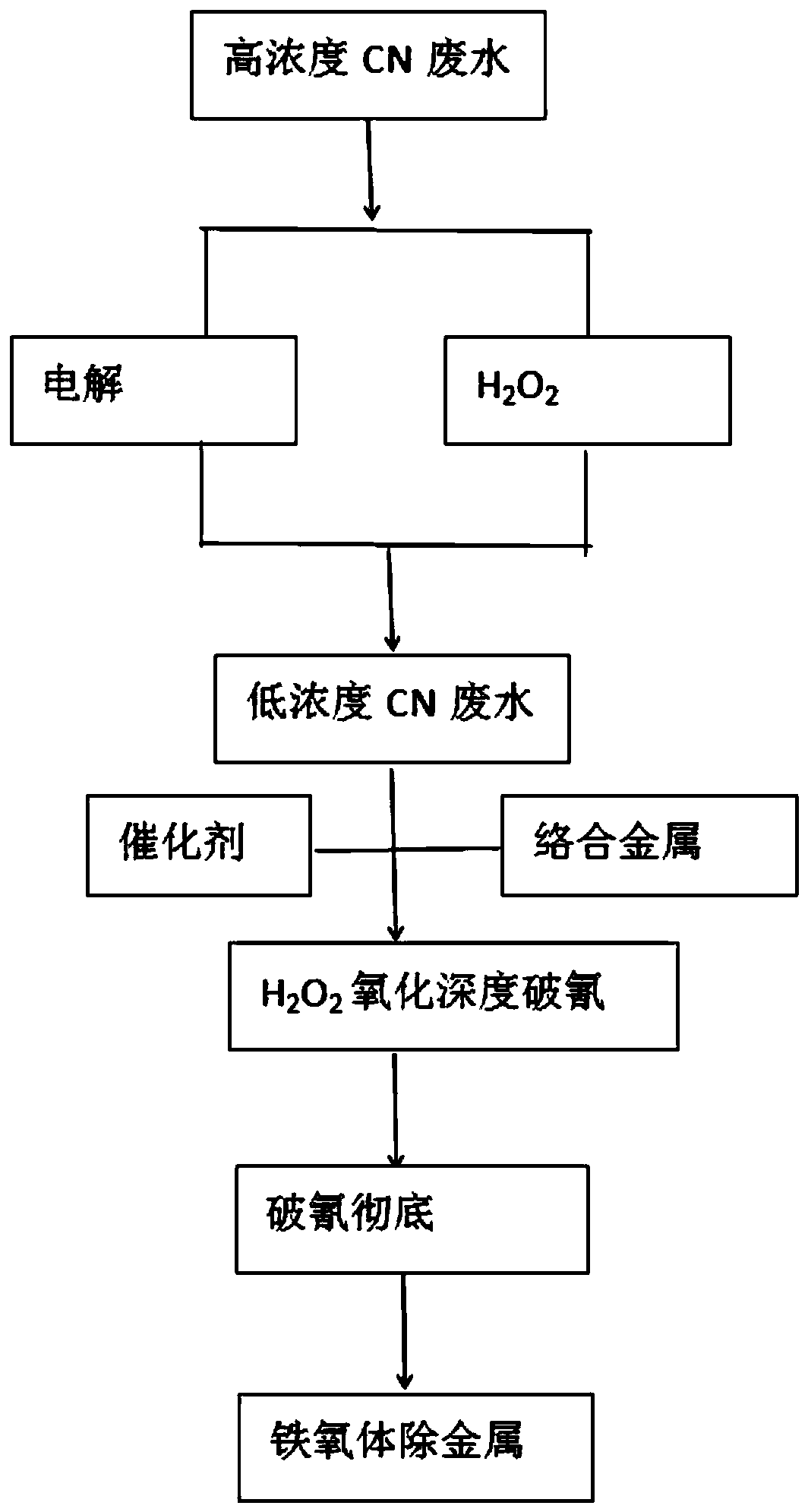

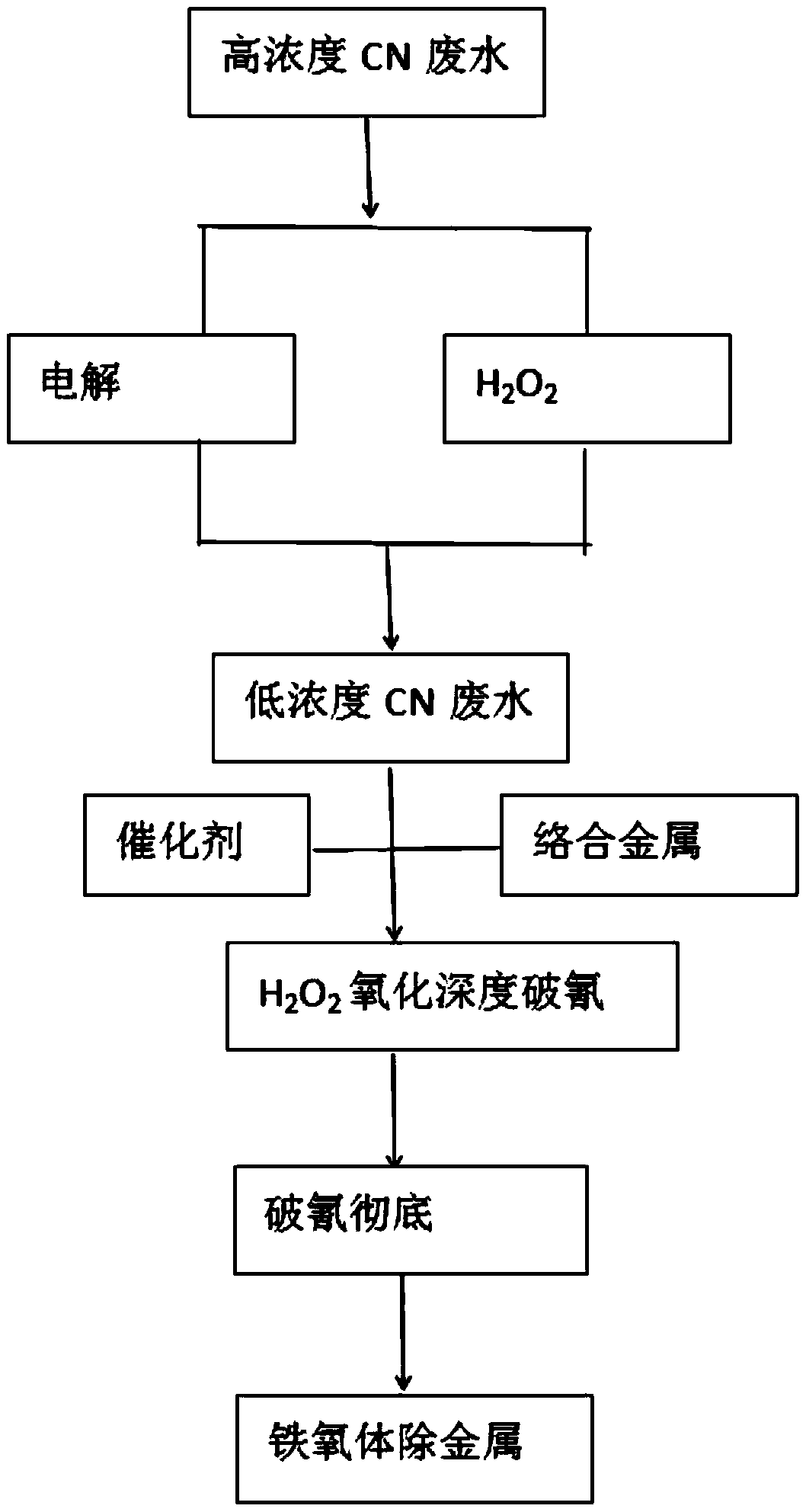

A method for removing heavy metals by breaking cyanide in high-concentration cyanide wastewater

A cyanide, high-concentration technology, which is applied in chemical instruments and methods, metallurgical wastewater treatment, water pollutants, etc., can solve the problems of HCN safety hazards, limited microbial load capacity, and high cost, so as to improve electrolysis efficiency and avoid subsequent reuse. The effect of low processing and reagent costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 500mL of cyanide wastewater from an electroplating factory. The main parameters of the raw water are: total cyanide: 15g / L, Fe content 35.2ppm, Zn content 2.5ppm, Ni content 5.6ppm, Cu content 10ppm.

[0031] Cyanide breaking and metal removal are mainly carried out through the following steps:

[0032] 1. Electrolysis: Pour 500mL wastewater into the electrolyzer, use NaOH / H 2 SO 4 Adjust the pH value to 10, use a cathode stainless steel plate, an anode titanium mesh plate, and adjust the current to 1.0A for constant current electrolysis.

[0033] 2. During the electrolysis process, add hydrogen peroxide in small amounts for several times, and the total volume of hydrogen peroxide added is 32.64mL.

[0034] 3. Stop the electrolysis when the cyanide is electrolyzed to 100ppm. The pH of the solution is 10. Turn on the heating tube. When the temperature rises to 60°C, add 5g of EDTA disodium salt and 0.25g of copper sulfate and react for 1 hour.

[0035] 4. Turn on...

Embodiment 2

[0039] Take 800mL of cyanide wastewater from an electroplating factory. The main parameters of the raw water are: total cyanide: 16g / L, Fe content 27.5ppm, Cu content 12ppm, Ni content 6.3ppm, Pb content 2.4ppm.

[0040] Cyanide breaking and metal removal are mainly carried out through the following steps:

[0041] 1. Electrolysis: Pour 500mL wastewater into the electrolyzer, use NaOH / H 2 SO 4 Adjust the pH value to 11, use a cathode stainless steel plate, an anode titanium mesh plate, adjust the current 10A, and perform constant current electrolysis.

[0042] 2. During the electrolysis process, add hydrogen peroxide in small amounts for several times, and the total volume of hydrogen peroxide added is 66mL.

[0043] 3. Stop the electrolysis when the cyanide is electrolyzed to 80ppm. The pH of the solution is 11. Turn on the heating tube. When the temperature rises to 70°C, add 18g of EDTA disodium salt and 0.64g of copper sulfate and react for 2 hours.

[0044] 4. Turn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com