Purifying apparatus for epoxypropane

A technology of propylene oxide and purification device, applied in the direction of organic chemistry, etc., can solve the problems of low concentration, waste of materials, high cost of extraction agent, and achieve the effect of reducing process energy consumption and improving technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

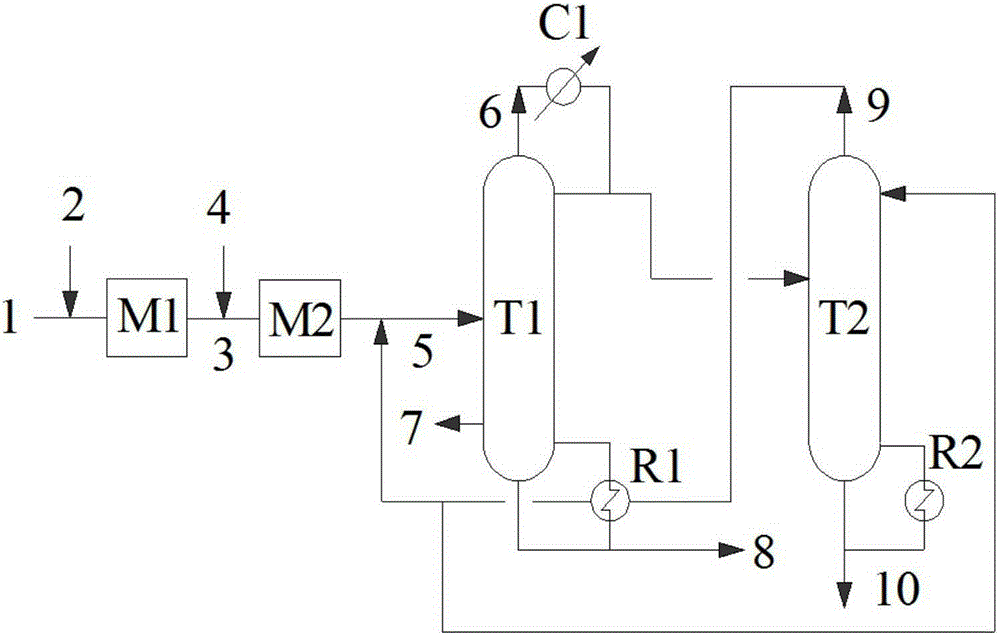

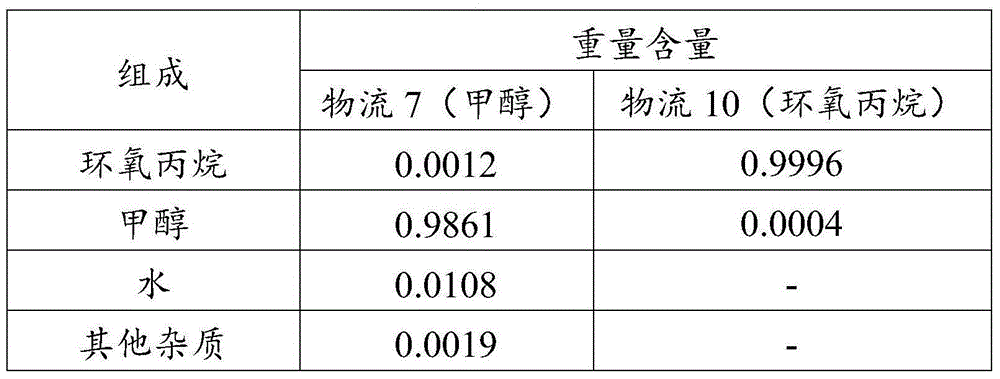

[0030] use figure 1 The composition of crude propylene oxide containing water, methanol, acetaldehyde, acetone, and methyl formate impurities in the shown device is shown in Table 1.

[0031] Table 1

[0032] composition weight content Methanol 0.26 Acetaldehyde 0.006 acetone 0.01 Methyl formate 0.01 water 0.01 other 0.004 Propylene oxide 0.7

[0033]The flow rate of crude propylene oxide 1 is 10000kg / h, reacts with stream 2 sodium hydroxide solution in the first mixer M1, methyl formate undergoes saponification reaction to produce methanol and sodium formate, and the reacted solution and stream 3 hydrazine solution are in the second mixer In the M2 reaction, carbonyl compounds such as acetaldehyde and acetone are reduced to produce hydrazone heavy components and water. After the reaction, the solution enters the upper part of the T1 tower. The number of theoretical plates in the T1 column is 40, the feeding position ...

Embodiment 2

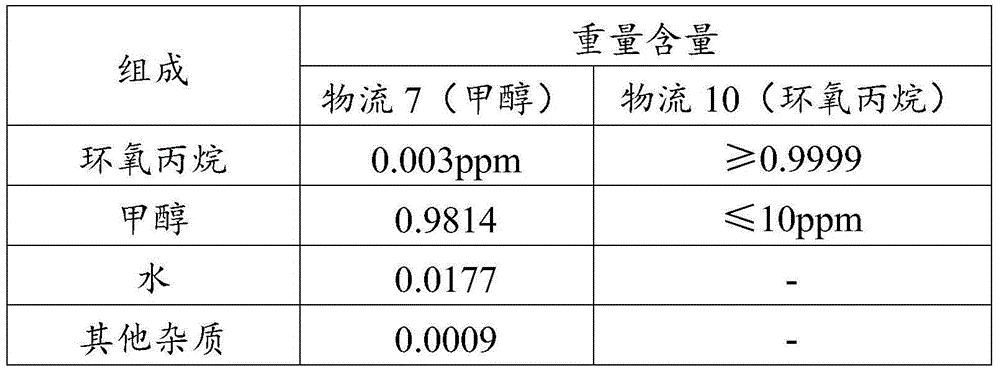

[0039] use figure 1 In the shown device, the composition of crude propylene oxide (stream 1) containing impurities such as methanol, acetaldehyde, acetone, methyl formate and water is shown in Table 3.

[0040] table 3

[0041] composition weight content Methanol 0.16 Acetaldehyde 0.008 acetone 0.007 Methyl formate 0.011 water 0.009 Propylene oxide 0.8

[0042] The flow rate of stream 1 is 10000kg / h, react with stream 2 sodium hydroxide solution in mixer M1, decompose methyl formate into methanol and sodium formate, react the solution with stream 3 hydrazine solution in mixer M2, and mix acetaldehyde, acetone The carbonyl compounds are reduced to produce hydrazone heavy components and water. After the reaction, the solution enters the upper part of the T1 tower. The theoretical plate number of the T1 column is 50, the feeding position is the 36th plate, the operating pressure is controlled at 80kPa, the reflux ratio is 6, t...

Embodiment 3

[0048] use figure 1 For the shown device, the composition of the crude propylene oxide solution (stream 1) containing impurities such as methanol, acetaldehyde, acetone, methyl formate and water is shown in Table 5.

[0049] table 5

[0050] composition weight content Methanol 0.07 Acetaldehyde 0.005 acetone 0.007 Methyl formate 0.006 water 0.01 Propylene oxide 0.9

[0051] The flow rate of stream 1 is 10000kg / h, react with stream 2 sodium hydroxide solution in mixer M1, decompose methyl formate into methanol and sodium formate, react the solution with stream 3 hydrazine solution in mixer M2, and mix acetaldehyde, acetone The carbonyl compounds are reduced to produce hydrazone heavy components and water. After the reaction, the solution enters the upper part of the T1 tower. The theoretical plate number of the T1 column is 60, the feeding position is the 45th plate, the operating pressure is controlled at 90kPa, the reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com